Full Auto False Ceiling Machine Exported to UAE

KINGREAL CEILING MACHINERY square metal false ceiling tile production line had been successfully delivered to Dubai, UAE. This perforated metal ceiling tile production line is for producing the standard 600*600mm aluminum and galvanized ceiling tile included 600*600MM CLIP IN ceiling tile, 600*600MM LAY IN ceiling tile.

Video About Metal Ceiling Tile Making Machine

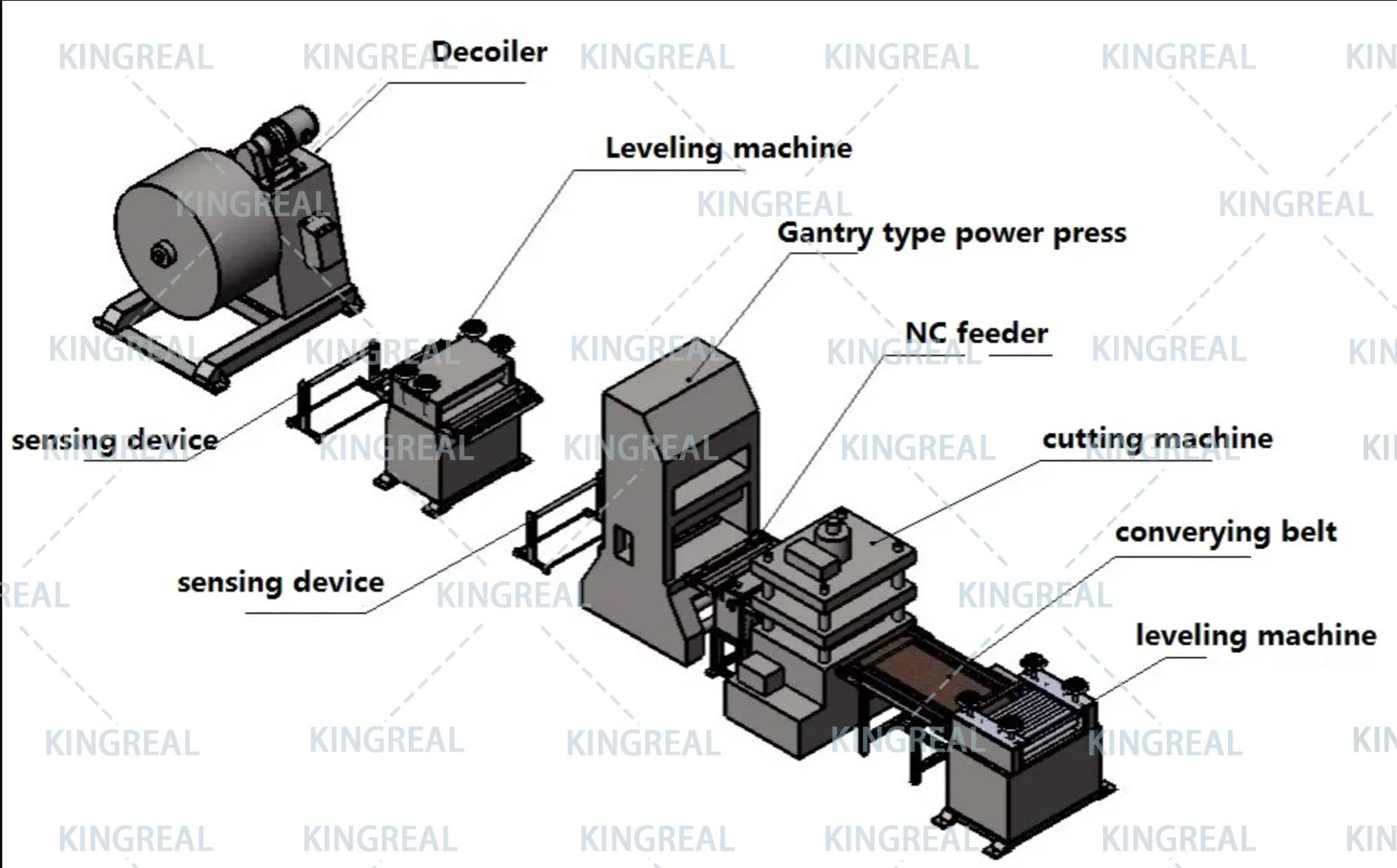

Working Process Of Metal Ceiling Tile Production Line

The basic procedure of 600*600mm full automatic square metal ceiling tile production line is uncoil the steel coil, then do the first flattening, after flattening then go the high speed perforation machine, after that it will cut to required length, and do the corner punch and panel forming automatically.

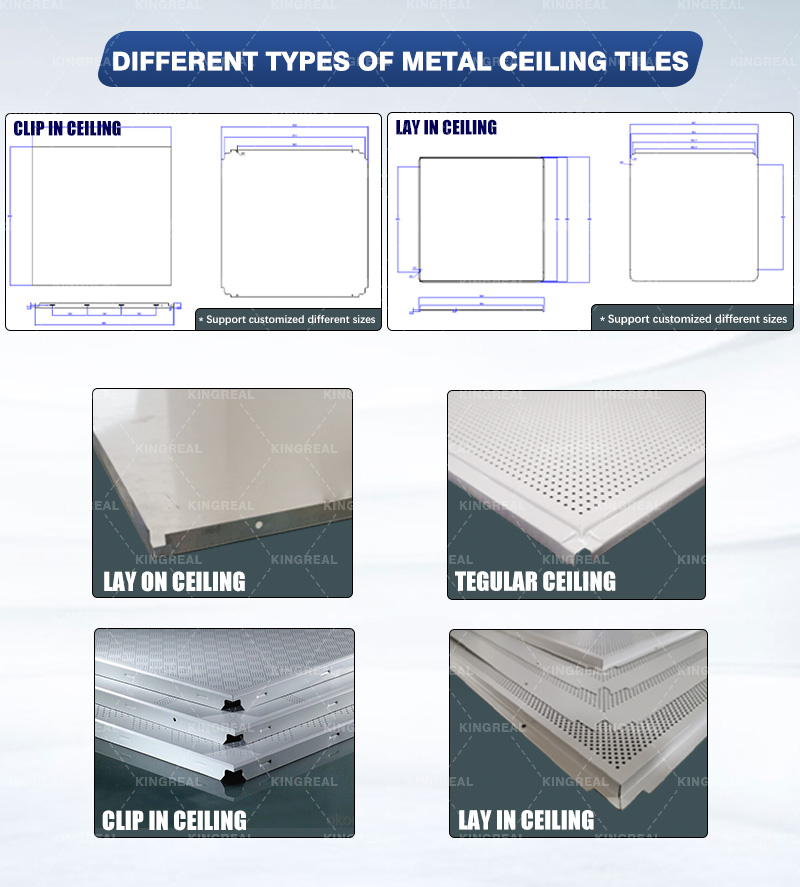

Different Types Of Ceilings Can Be Produced

KINGREAL CEILING MACHINERY full automatic false ceiling tile production line can produce LAY IN ceiling tile and CLIP IN ceiling tile on the same production line by changing the notching mold and bending forming molds. For LAY IN ceiling tile, there are different types on markets, most popular is 575*575mm exposed for T24 system and 585*585mm exposed for T15 system. These two kinds of metal ceiling tile also need to be produced by changing the notching and bending forming molds.

Main Components Of Metal Ceiling Tile Production Line

KINGREAL CEILING MACHINERY UAE false ceiling tile production line is featured with high speed, stable output, low faults and high performance. The metal ceiling tile notching and shearing is finished in one step to ensure the size more accurate and the procedure easier.

KINGREAL CEILING MACHINERY offer full automatic production line for the metal ceilings, including auto decoiler, auto straightener, auto perforation, auto notching & shearing, auto washing & drying, auto tiles turn, auto bending forming. KINGREAL CEILING MACHINERY can design the production line according with customers' request of different procedures, different dimensions and etc.

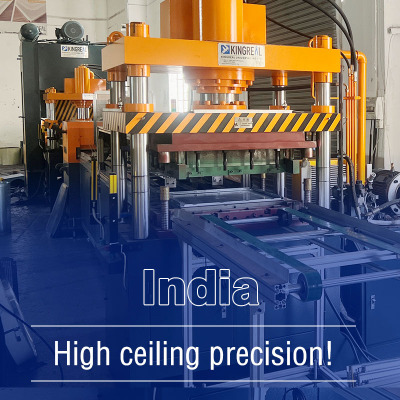

KINGREAL CEILING MACHINERY INDIA 60*60CM CLIP IN/ LAY IN ceiling tile production line is controlled by PLC, and the metal ceiling tile making machine use high quality YASKAWA servo feeder motor to ensure the accurate of the production.

The metal ceiling tile making machine can produce both CLIP in ceiling tile and LAY in ceiling tile. When produce different types of ceiling tiles, it needs to change the notching & shearing molds set, also the bending forming molds set. KINGREAL CEILING MACHINERY metal false ceiling tile production line can produce both steel ceiling tile and also aluminum ceiling tile. When producing different materials, it needs to change the perforation molds.

KINGREAL CEILING MACHINERY hydraulic ceiling tile bending forming machine can do the ceiling plates bending forming full automatically, the perforated sheet can be sent to the hydraulic bending forming press automatically by the manipulator. Then the hydraulic press will do the bending forming, after the ceiling tile bending forming, it will be pushed out. At the same time, one new perforated sheet will be put into the hydraulic press.

KINGREAL CEILING MACHINERY hydraulic ceiling tile bending forming machine is 140ton high capacity hydraulic press, and it will be equipped with fan cooling system and also water cooling system to reduce the temperature of hydraulic oil. This will ensure the continuously running of the machine and production line, which can also fit the hot weather of Dubai, Abu Dhabi of UAE.

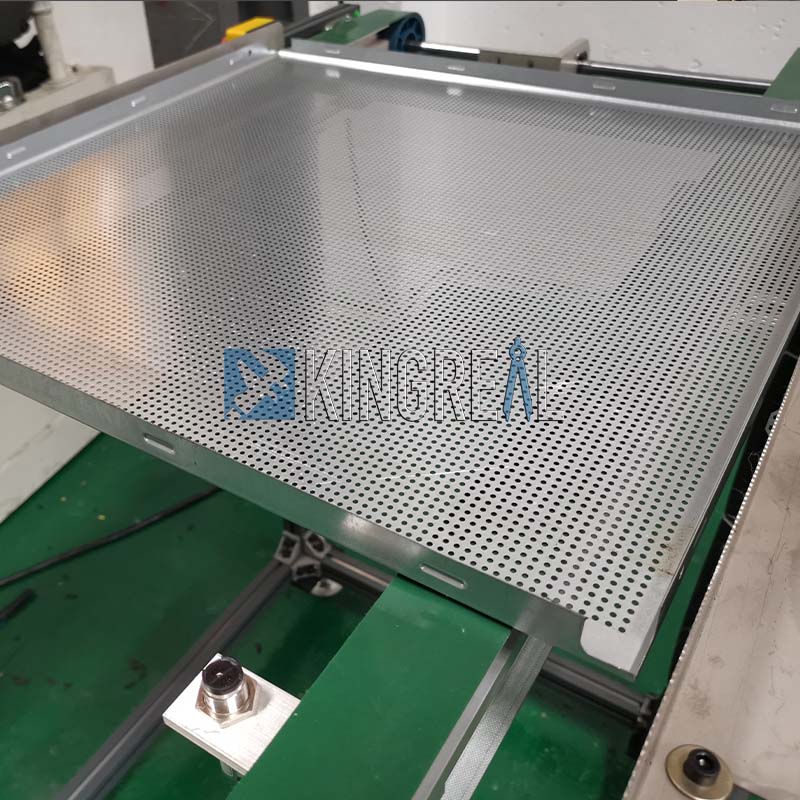

KINGREAL CEILING MACHINERY precision straightener can ensure the levelness of the perforated sheet. KINGREAL CEILING MACHINERY precision leveller is special designed 21 rollers to level the perforated sheet.

We use four-column oil press for the corner cutting and bending forming. For corner cutting, we use the same mould to produce aluminum ceiling tile production and galvanized steel ceiling tile production. While for the bending forming, due to different thickness of the aluminum and galvanized steel, we suggest to use different mould to do the bending forming.

There are clip in, lay on, lay in type for the ceiling panels, molds need to be changed when producing different types of ceiling tiles.

KINGREAL CEILING MACHINERY full automatic ceiling tile production line has auto tile turn machine. After perforated, the aluminum sheet has burrs on the backside, so it will has to be auto turned. We use automatic manipulator for the corner cutting and bending forming. This is first choice for the ceiling tile production line manufacturer. Which can save a lot of labor cost for the manufacturer.

KINGREAL CEILING MACHINERY uses 120 ton high speed gantry press to do the metal ceiling tile perforation. For the aluminum ceiling tile it can perforate 8 rows each time, for the galvanized steel it can perforate 4 rows each time.

The perforation mould is also very important for the final ceiling tile products quality. We choose high quality wire cut molds to do the perforation. For aluminum ceiling tiles and galvanized ceiling plates, we use different mould to ensure the quality.

KINGREAL CEILING MACHINERY metal ceiling tile production line is full automatic operation including automatic decoiler, straightener, high speed ganty press, servo feeder, hydraulic notching & shearing, and precision straightener. This metal perforation is full automatic operation and featured with high speed, low labor cost and easy to operation.

Customer Feedback in UAE

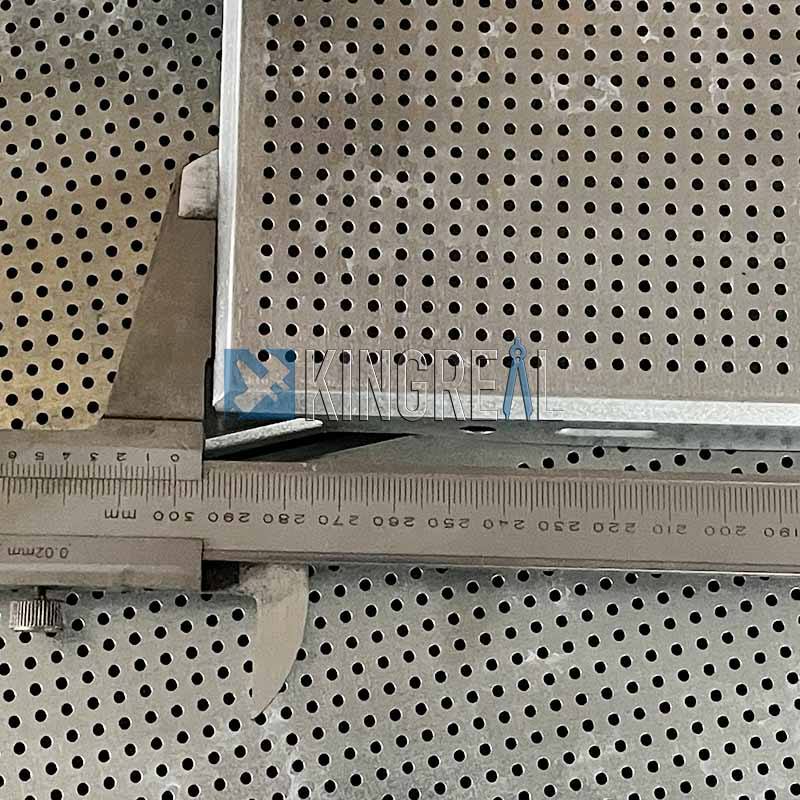

KINGREAL CEILING MACHINERY's metal ceiling production line has received high praise from customers in the UAE. After using it for a period of time, the customer gave feedback to KINGREAL CEILING MACHINERY's staff: "This metal ceiling production line runs very smoothly, and the metal ceilings produced are extremely accurate, which makes us feel confident and believe that we can become bigger and stronger in the industry and further enhance the reputation of the ceiling business. It is worth mentioning that the error range in the production process is only within ±0.1mm. In addition, the ceiling surface is smooth, burr-free, and the consistency of the product is also very high."

KINGREAL CEILING MACHINERY sincerely thank the UAE customer for his high evaluation of KINGREAL CEILING MACHINERY's metal ceiling production line. As a metal ceiling machine manufacturer with more than 20 years of rich experience, KINGREAL CEILING MACHINERY has established good cooperative relations with customers in many countries such as India, Bangladesh, Russia, Saudi Arabia, etc. In addition to the repeatedly praised quality of metal ceiling making machines, KINGREAL CEILING MACHINERY's one-stop service is also well received.

KINGREAL CEILING MACHINERY focuses on providing comprehensive support to customers, including sending professional staff to accompany customers to visit the factory and explain the technical details of the metal ceiling production line in detail. In addition, KINGREAL CEILING MACHINERY invites customers to meet with KINGREAL CEILING MACHINERY engineers to discuss and develop customized metal ceiling machine manufacturing solutions.

After the metal ceiling making machine is manufactured, KINGREAL CEILING MACHINERY will strictly conduct the test phase to ensure that the products produced fully meet customer needs and all parameters are consistent with the previous plan before sending them to the customer's factory. In order to ensure smooth production, KINGREAL CEILING MACHINERY will also send engineers to the customer's factory to install the metal ceiling production line to ensure that every detail achieves the best effect.

Get the latest price? We'll respond as soon as possible(within 12 hours)