How many types of metal ceiling machines are there?

2025-04-21 17:00

In modern architecture and interior design, the role of the metal ceiling is not only to cover the structural beams and pipes, but also an important element to enhance the beauty of the space and improve the acoustic effect. As a metal ceiling machine manufacturer with more than 20 years of rich experience, KINGREAL CEILING MACHINERY is committed to customizing various types of metal ceiling panel production lines according to the diverse needs of customers. This article will introduce the different types of metal ceiling machines provided by KINGREAL CEILING MACHINERY in detail to help customers better understand the available solutions.

1. Fully Automatic and Semi-automatic Metal Ceiling Machines

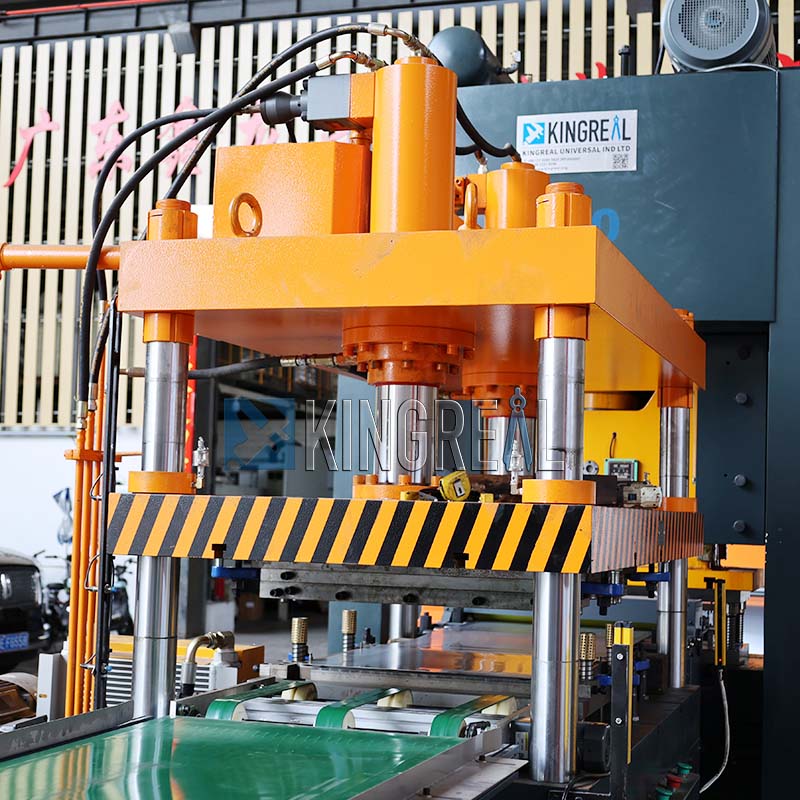

1.1 Fully automatic metal ceiling panel production line

The fully automatic aluminum ceiling tile machine is a representative of modern production and integrates advanced automation technology. The aluminum ceiling tile machine can complete the entire production process from raw materials to finished products without human intervention. The key features of the fully automatic aluminum ceiling tile machine include:

Highly automated components: Equipped with a variety of automated equipment, such as the automatic tiles feeding machine and the tiles flipping machine, these components can realize automatic loading, flipping and handling, reduce manual intervention, and improve production efficiency.

Automated control system: Through the intelligent control system, the production status can be monitored in real time to ensure high efficiency and stability in the production process.

High-speed production capacity: Fully automatic aluminum ceiling tile machines can quickly complete large-scale production tasks and are suitable for large-scale industrial production needs.

Fully automatic aluminum ceiling tile machines have the advantages of high output, low labor costs and high consistency, and are suitable for customers with strict requirements on quality and efficiency.

1.2 Semi-automatic metal ceiling machine

Semi-automatic metal ceiling panel production lines require certain human intervention during the production process and are suitable for customers with small production scales or who need flexible adjustments. This metal ceiling machine usually has the following characteristics:

Combination of manual operation and automation: Some steps still require manual operation, such as feeding manipulators and flip machines. Due to the lack of high-end equipment on fully automatic metal ceiling panel production lines, the operation of semi-automatic aluminum ceiling tile machines is relatively simple.

Flexibility: Semi-automatic aluminum ceiling tile machines can quickly adjust production parameters according to the specific needs of customers to adapt to different types of ceiling products.

Semi-automatic metal ceiling machines are suitable for small and medium-sized enterprises or customers with customized production needs, and can flexibly respond to market changes while maintaining a certain output.

2. Different Types of Metal Ceiling Machines

2.1 Metal ceiling machine for clip in ceiling

Clip in ceiling is a type of ceiling with high decorativeness and practicality, usually used in commercial spaces and high-end residences. KINGREAL CEILING MACHINERY Clip in metal ceiling machine can produce a variety of clip in ceilings to meet the personalized needs of customers. During the production process, the metal ceiling panel production line can efficiently complete processes such as molding and surface treatment to ensure the quality and beauty of each ceiling.

2.2 Metal ceiling panel production line for lay in ceiling

Lay in ceiling is a common ceiling system widely used in offices, shopping malls and public buildings. This type of aluminum ceiling tile machine focuses on manufacturing standardized ceiling components, which has the advantages of easy installation and easy maintenance. KINGREAL CEILING MACHINERY lay in metal ceiling machine is equipped with advanced processing equipment, which can quickly produce lay in ceilings that meet industry standards to ensure product consistency and stability

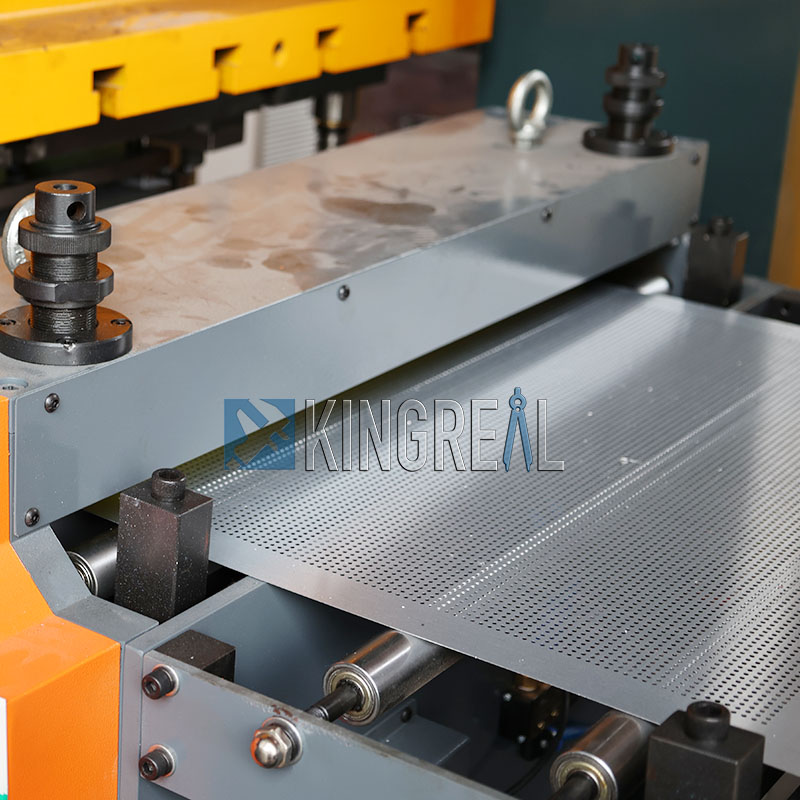

3. Production of Perforated Ceilings

Perforated ceilings are widely popular for their unique aesthetics and good acoustic performance. KINGREAL CEILING MACHINERY metal ceiling panel production line can be used in conjunction with the metal ceiling perforation line to achieve efficient punching production. Through precise punching molds, the produced ceilings not only have a beautiful appearance, but also have well optimized acoustic effects.

3.1 Advantages of punching technology

The design of the perforated ceiling allows sound to be transmitted through the holes, thereby improving the indoor acoustic environment. Suitable for cinemas, concert halls and other places that require good acoustic effects. KINGREAL CEILING MACHINERY metal ceiling perforation line can customize holes of different shapes and sizes according to customer needs through an efficient punching process to meet specific acoustic requirements.

4. Equip Metal Ceiling Machine with Various Components

In order to meet the customized needs of customers, KINGREAL CEILING MACHINERY has equipped the aluminum ceiling tile machine with a variety of accessories and auxiliary equipment. The addition of these components not only improves production efficiency, but also enhances the functionality of the ceiling.

4.1 Acoustical ceiling tile textile stick machine

The main function of the acoustical ceiling tile textile stick machine is to provide sound absorption for the ceiling. By sticking special sound-absorbing materials on the surface of the ceiling, the echo in the room can be effectively reduced and the comfort of the space can be improved. KINGREAL CEILING MACHINERY acoustical ceiling tile textile stick machine is simple in design and can work seamlessly with the metal ceiling machine to quickly complete the patching operation.

4.2 Metal sheets cleaning degreasing machine

The metal sheets cleaning degreasing machine is used to clean the surface of the produced ceiling to remove oil and dust. Keeping the ceiling clean not only helps to improve the appearance quality of the product, but also prolongs its service life. KINGREAL CEILING MACHINERY metal sheet cleaning machine uses high-pressure water flow and environmentally friendly cleaning agents to ensure cleaning results while reducing the impact on the environment

Get the latest price? We'll respond as soon as possible(within 12 hours)