What's wall panel cladding machine?

2025-02-25 17:00

Introduction of wall panel cladding making machine

Wall panel cladding production line is a kind of equipment specially used to process metal coils into wall panels. The wall panel cladding making machine converts metal materials into wall panels for construction through a series of process steps, including uncoiling, leveling, forming and cutting. With the development of the modern construction industry, wall panels are more and more widely used in residential, commercial and industrial construction projects, and their market demand is growing.

Due to the advantages of easy installation and maintenance of wall panels, more and more construction projects tend to use wall panel materials. Against this background, the demand for wall panel cladding making machines has also increased, becoming an indispensable equipment in modern construction projects.

Main components of wall panel cladding production line

The working process of wall panel cladding making machine consists of several key components, each of which plays an important role in the entire production process.

Decoiler

The decoiler is the first process of the wall panel cladding machine, which is responsible for the automatic uncoiling of metal coils. The decoiler ensures that the metal coils are smoothly transported to the subsequent processes to avoid affecting the production efficiency due to the distortion or overlap of the coils. An efficient decoiler can not only improve production efficiency, but also reduce manual operation and improve safety.

Straightener

Straightener is used to level the surface of metal coils for subsequent forming operations. Straightener eliminates the corrugation and unevenness of metal coils by flattening and stretching to achieve the ideal flatness. The leveled metal material can improve the forming accuracy and ensure the quality of the final wall panels.

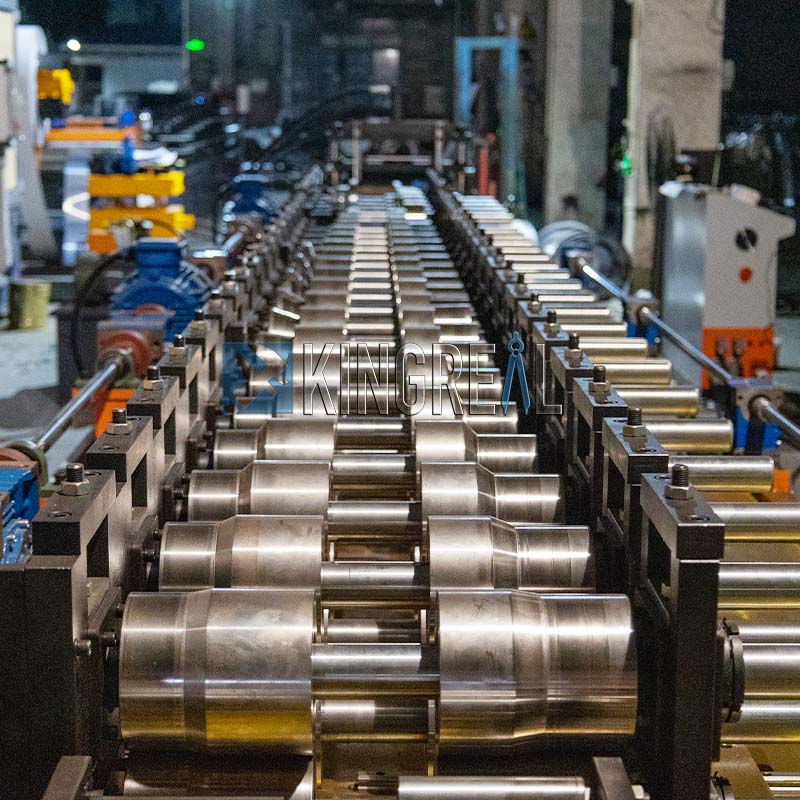

Roll forming machine

Roll forming machine is the core component of the wall panel cladding production line. It rolls the metal raw materials through rollers to form various types of wall panels. The design and construction of the roll forming machine directly affect the shape and thickness of the wall panel. KINGREAL CEILING MACHINERY's roll forming machine has an adjustable roller configuration and can produce wall panels of different specifications to meet the diverse needs of customers.

Cutting station

The cutting station is used to shear the produced wall panels according to the actual needs of the customer. The cutting station accurately cuts the wall panel according to the set length and specifications to ensure that each wall panel meets the customer's requirements. The automated design of this process not only improves production efficiency, but also reduces the errors caused by human operation.

Advantages of wall panel cladding machine

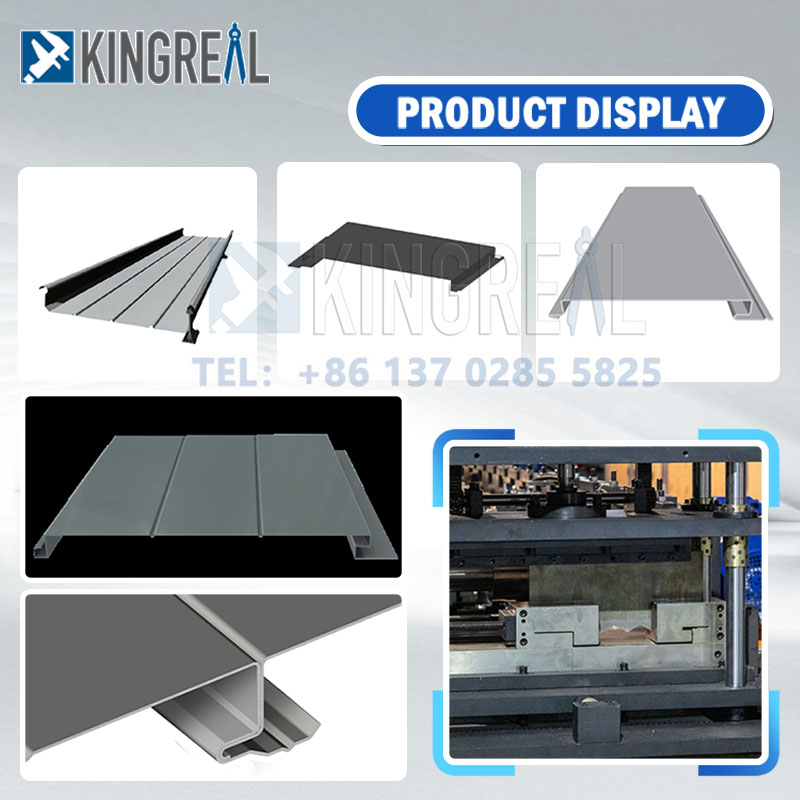

Suitable for different places

KINGREAL CEILING MACHINERY's wall panel cladding machine can produce wall panels suitable for different places, including offices, conference rooms, airports, hotels, etc. KINGREAL engineers will make customized wall panel cladding making machine manufacturing plans based on the customer's drawings to ensure that KINGREAL's wall panel cladding production line is suitable for the places required by the customer.

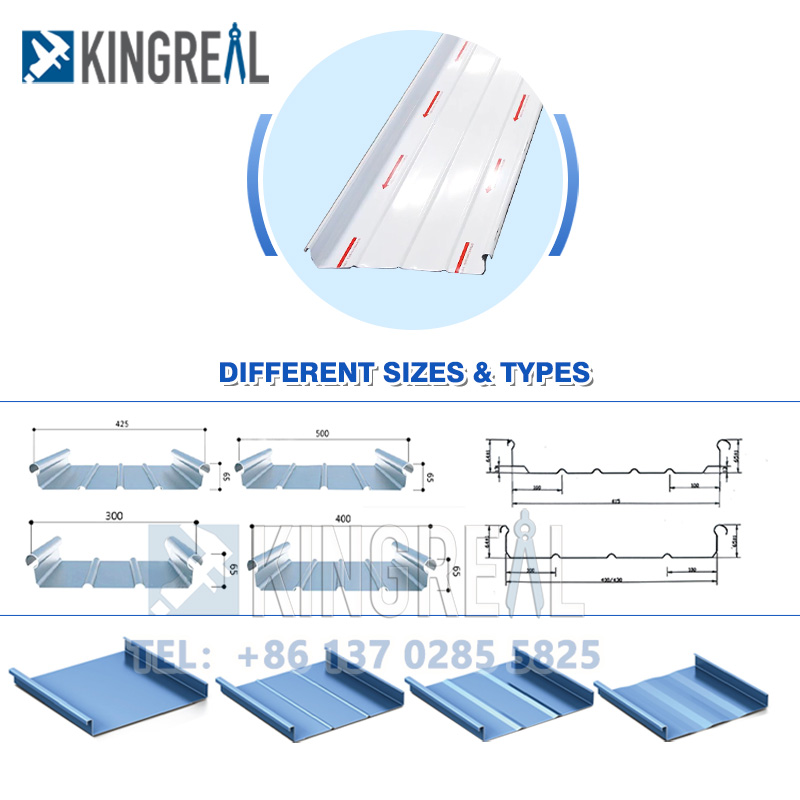

Can produce different sizes

The forming machine has flexible production capabilities and can produce wall panels of different sizes on a wall panel cladding production line. This flexibility allows customers to adjust production according to actual needs and reduce inventory pressure.

Full automation

KINGREAL CEILING MACHINERY's wall panel cladding machine adopts a fully automated design, which reduces manual intervention and reduces production costs. The increase in automation not only improves production efficiency, but also improves product consistency and quality.

Can produce different types of wall panels

KINGREAL CEILING MACHINERY has designed a variety of production solutions for various common types of wall panels on the market, such as flat panels, v-ribs, pencil ribs or clip reliefs, and customers can choose the most suitable molding machine according to their needs.

Get the latest price? We'll respond as soon as possible(within 12 hours)