Video Display

Video Display Description Of Full Auto Suspended Ceiling Tiles Production Line

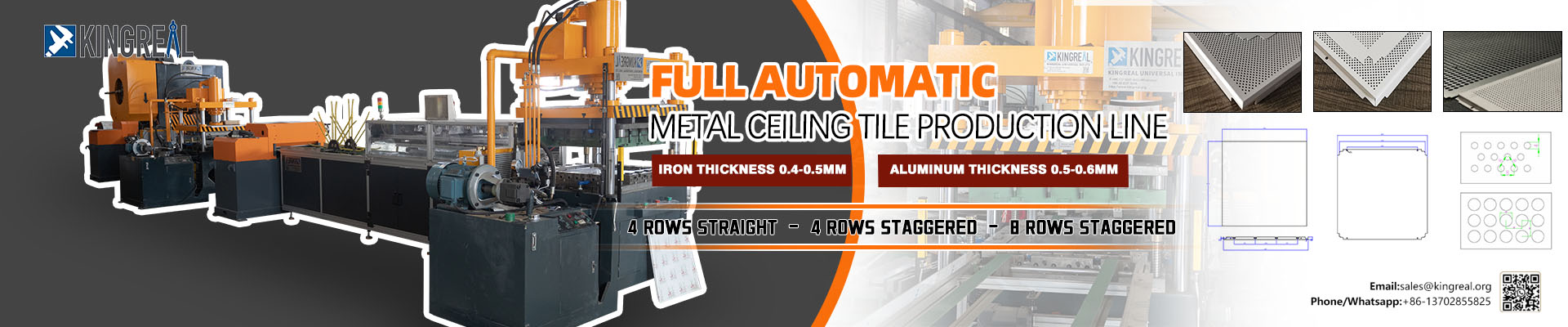

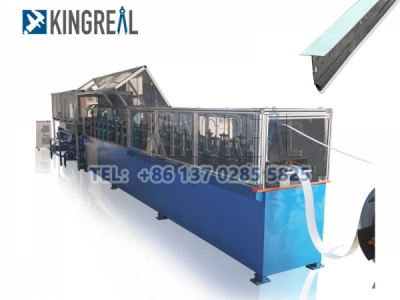

Description Of Full Auto Suspended Ceiling Tiles Production LineKINGREAL Full Auto Suspended Ceiling Tiles Production Line is one of our features product, which is design for specifically designed to automate the production of ceiling products of different sizes, including both lay-in and clip-in types.

This metal ceiling production line can realize a series of fully automatic production processes from decoiler, leveling, punching, washing and so on.

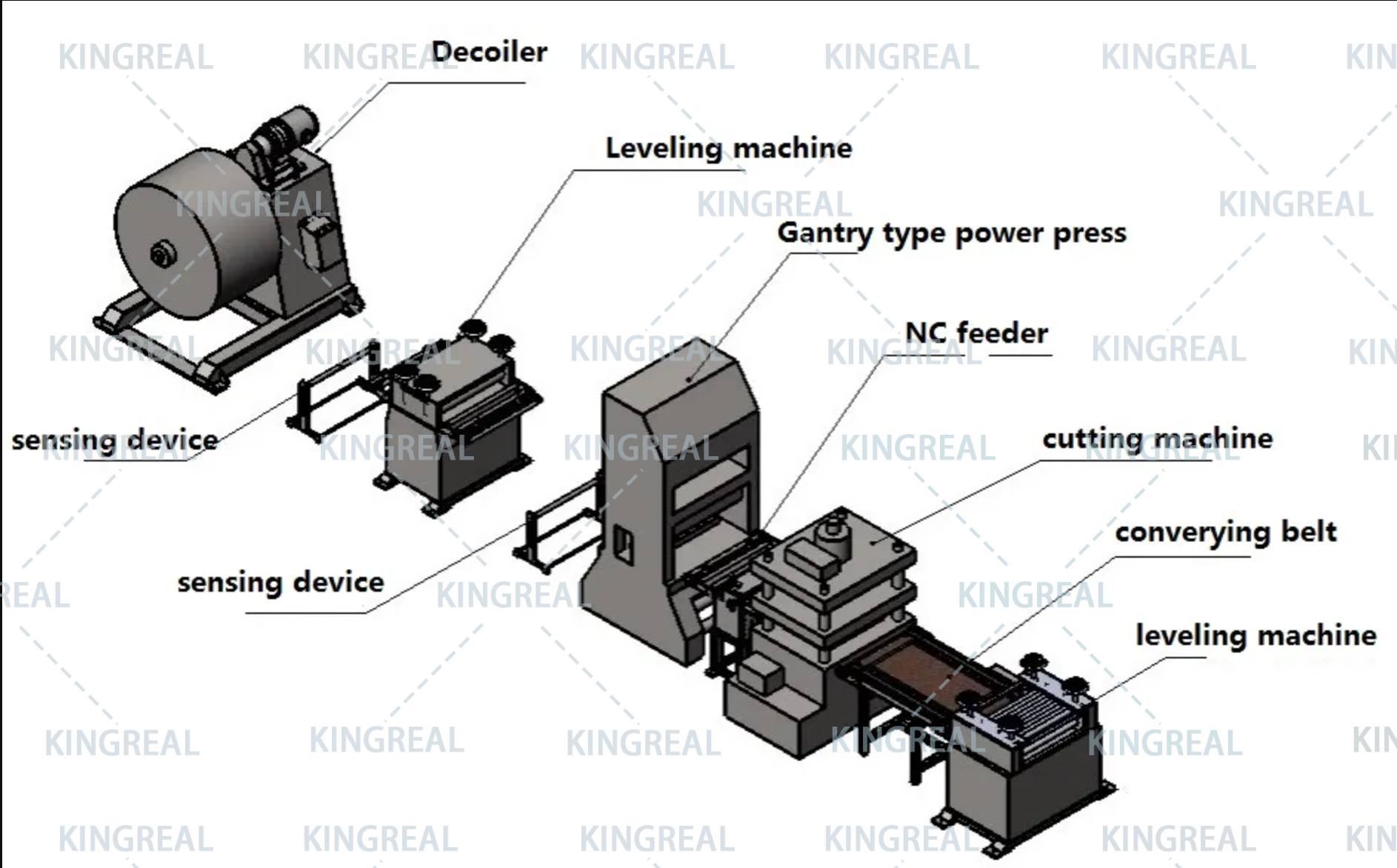

Composition Of Complete Production Line

Composition Of Complete Production Line

| Machine | Features | Amount |

| Decoiler | Hydraulic expansion | 1 Unit |

| Pre-straightener | High-precision 19 Rollers | 1 Unit |

| 125 Tons High-Speed Perforation Press | 125Tons, 100-150 SPM, 2-5PCS tiles/min | 1 Unit |

| NC Servo feeding machine | Yaskawa Servo motor, 3.0KW High accuracy | 1 Unit |

| Hydraulic notching & shearing press | 60tons Hydraulic press, High accuracy | 1 Unit |

| Transmission conveyor | Automatic | 2 Units |

| Precision straightener | High-precision 21 Rollers | 1 Unit |

| Automatic tiles flipping machine | For flipping 600*600 tiles 180 degrees | 1 Unit |

| Automatic feeding mechanical arm | For feeding 600*600 tiles to next step production | 1 Unit |

| Hydraulic bending forming press | For bending forming 600*600 tiles | 1 Unit |

| Electric control system | Reliable parts | 1 Unit |

Main Components Of Metal Ceiling Tiles Machine

Main Components Of Metal Ceiling Tiles Machine

|

- Hydraulic Decoiler - First leveling - High-Speed Gantry with NC feeding perforation - Corner cutting - Second precision leveling - Manipulator - Bending - Degrease Part |

|

Working Process Of This Production Line

Working Process Of This Production Line

Specification Of Metal Ceiling Press Machine

Specification Of Metal Ceiling Press Machine

|

Sizes of material |

610 x 610 mm (Lay-in) |

|

Thickness of material |

0.3-0.4 mm (GI Steel) 0.5-0.6 mm (Aluminum) |

|

Inner diameter |

Φ 500 |

|

Outer diameter |

Φ 1200 |

|

Maximum load |

5 tons |

|

Width of material |

<700 mm |

|

Feeding speed |

16m / min |

|

Punching stroke |

20 mm |

|

Punching pierce |

120-160times/min |

Machine Feature

Machine Feature

|

Hydraulic Decoiler The hydraulic decoiler has an automatic feeding frame, and it needs manual input for materials. |

|

|

High-Speed Gantry Press Machine We use 120-ton high speed gantry press to punch the holes. This machine uses pneumatic brake system to replace the old gear drive system. This will ensure the accurate perforation and higher speed production. |

|

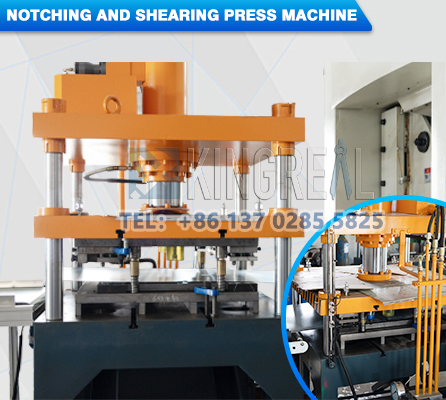

Notching and Shearing Press Machine Our 2-in-1 notching, and shearing press machine can do corner-cutting and cut-to-length at the same time, which saves time and improves productivity. |

|

Quality Assurance

Quality Assurance

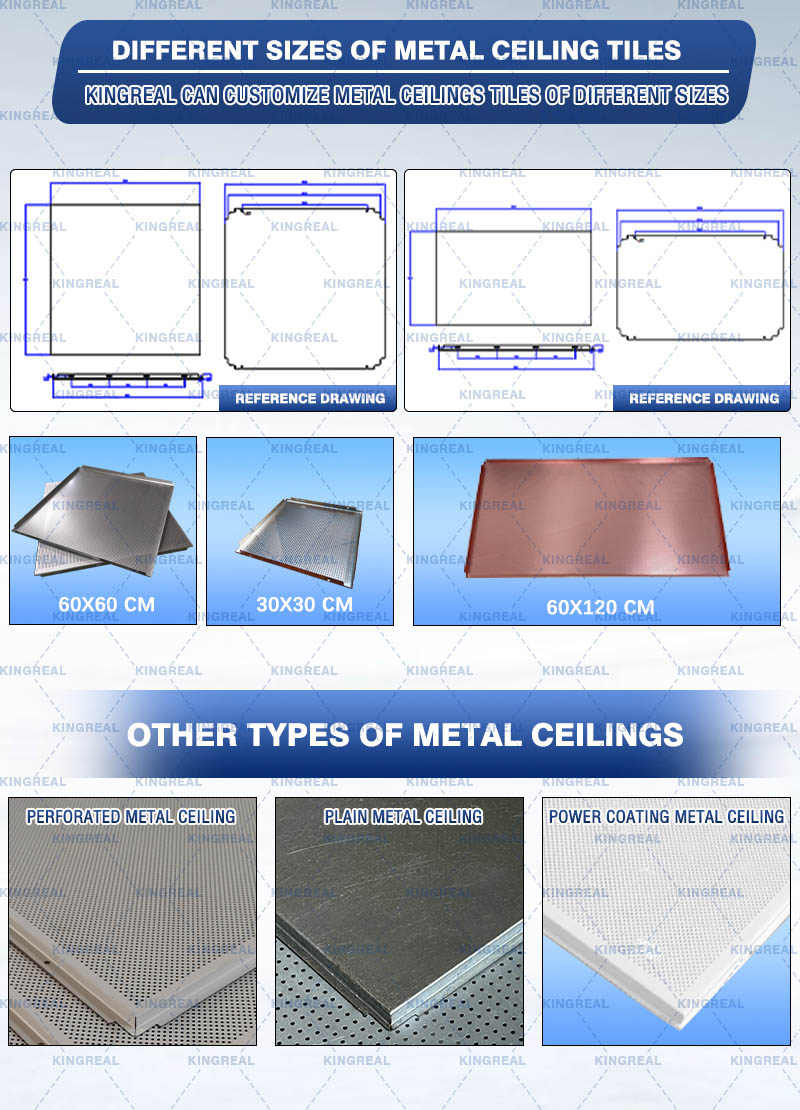

What Metal Ceiling Tiles Can Be Produced By KINGREAL Production Line

What Metal Ceiling Tiles Can Be Produced By KINGREAL Production Line

Installation Service Case

Installation Service Case