Video Display

Video Display

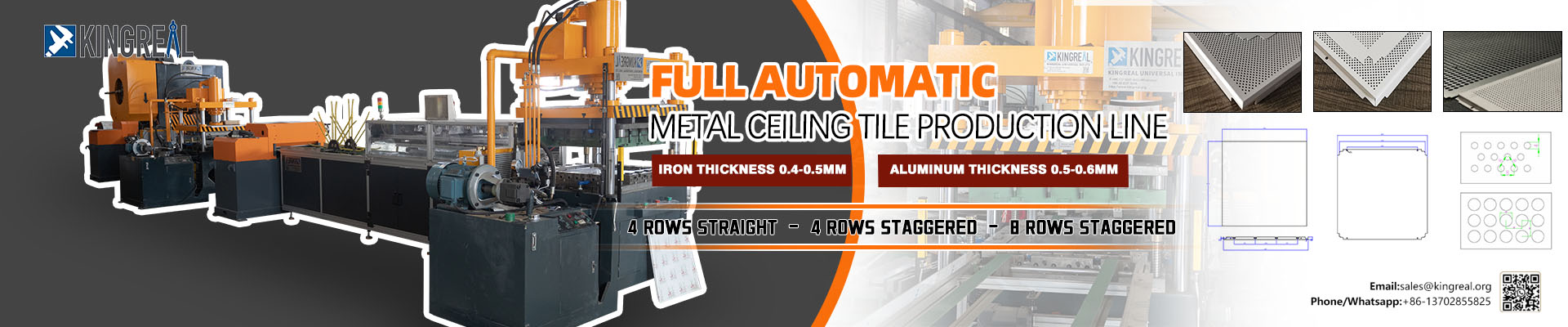

Description Of Clip In Metal Ceiling Tiles Production Line

Description Of Clip In Metal Ceiling Tiles Production Line

KINGREAL Clip In Metal Ceiling tile Production Line is design for produce swing down ceiling panel, Which can automate the process of processing, notching and shearing,punching, painting and washing the ceiling panels, effectively improving production efficiency and quality control.

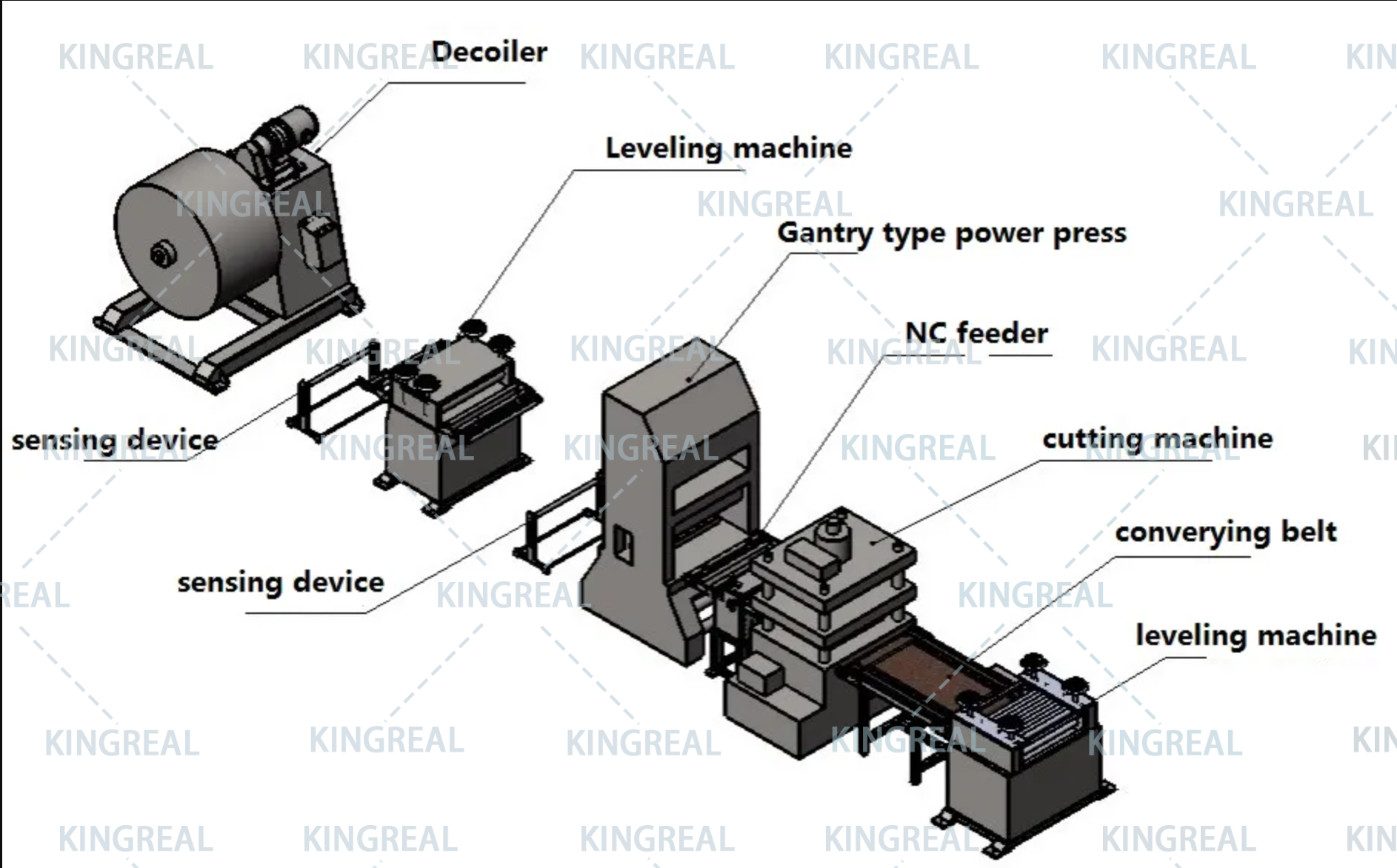

Composition Of Complete Production Line

Composition Of Complete Production Line

| Machine | Features | Amount |

| Decoiler | Hydraulic expansion | 1 Unit |

| Pre-straightener | High-precision 19 Rollers | 1 Unit |

| 125 Tons High-Speed Perforation Press | 125Tons, 100-150 SPM, 2-5PCS tiles/min | 1 Unit |

| NC Servo feeding machine | Yaskawa Servo motor, 3.0KW High accuracy | 1 Unit |

| Hydraulic notching & shearing press | 60tons Hydraulic press, High accuracy | 1 Unit |

| Transmission conveyor | Automatic | 2 Units |

| Precision straightener | High-precision 21 Rollers | 1 Unit |

| Automatic tiles flipping machine | For flipping 600*600 tiles 180 degrees | 1 Unit |

| Automatic feeding mechanical arm | For feeding 600*600 tiles to next step production | 1 Unit |

| Hydraulic bending forming press | For bending forming 600*600 tiles | 1 Unit |

| Electric control system | Reliable parts | 1 Unit |

What Is Clip In Swing Down Metal Ceiling?

What Is Clip In Swing Down Metal Ceiling?

Clip In swing down ceiling tile is a kind of ceiling panel which is easy to install and beautiful to look at.

It is made of aluminum alloy or other metal materials, has the structural characteristics of plywood, and is fixed to the ceiling keel or wood keel by the installation of snap or hook and other devices.

In addition to this ceiling line, KINGREAL offers several ceiling lines as follows:

1. Full Automatic Metal Ceiling Production

2. Semi-Auto Square Metal Ceiling Tile Production Line

3. Clip-In Ceiling Tile Production Line

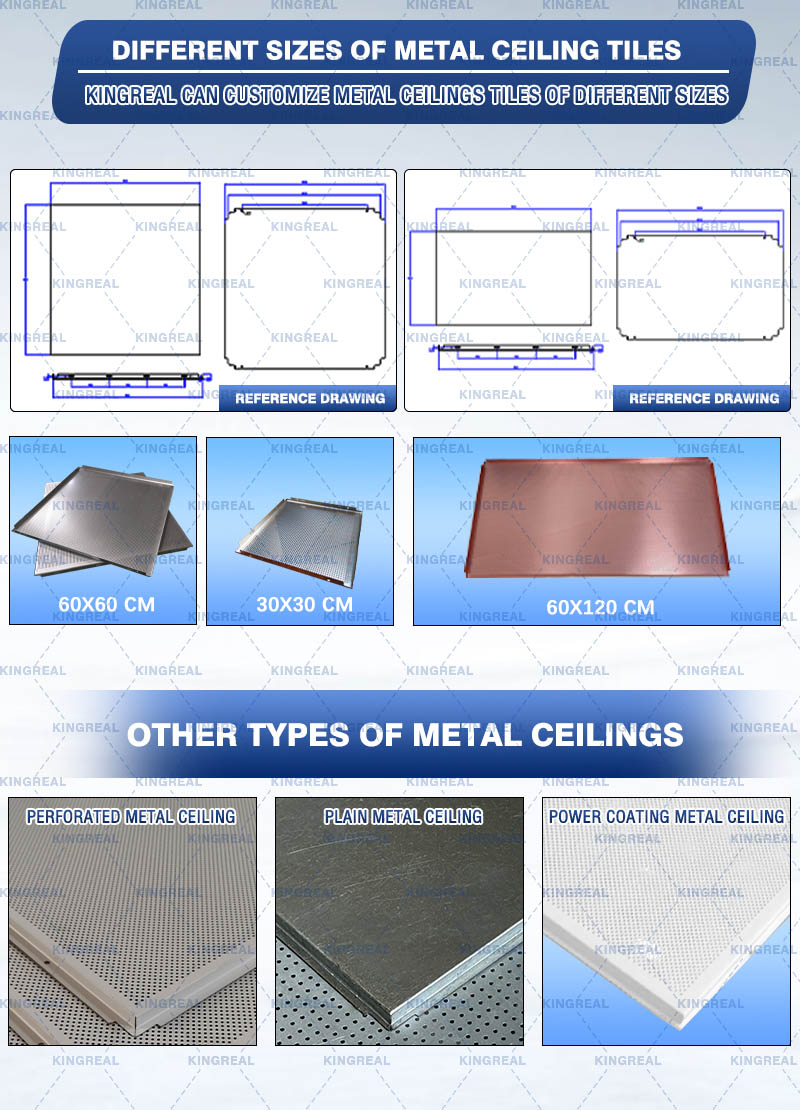

4. 30cm*30cm, 60cm*60cm, 60cm*120cm Metal Ceiling tile Machine

KINGREAL Successful Cases in Global

KINGREAL Successful Cases in Global

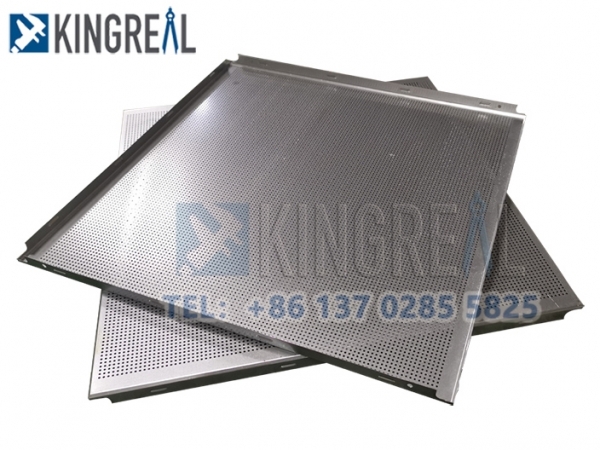

Which Type Of Metal Ceiling Tiles Can Be Produced?

Which Type Of Metal Ceiling Tiles Can Be Produced?

Working Procedure Of This Clip in Tile Ceiling Production Line

Working Procedure Of This Clip in Tile Ceiling Production Line

Hydraulic decoiler -- Pre-straightener -- NC Servo Feeder -- Gantry press for perforation -- Precision straightener-- Automatic cleaning and drying machine-- Conveyor-- Automatic turning machine -- Automatic positioning machine and mechanical arm -- Automatic hydraulic press for bending forming

Technical Specification Of Metal Ceiling Tile Production Line

Technical Specification Of Metal Ceiling Tile Production Line

| Sizes of material | 610 x 610 mm (Lay-in) |

| Thickness of material | 0.3-0.4 mm (GI Steel) 0.5-0.6 mm (Aluminum) |

| Inner diameter | Φ 500 |

| Outer diameter | Φ 1200 |

| Maximum load | 5 tons |

| Width of material | <700 mm |

| Feeding speed | 16m / min |

| Punching stroke | 20 mm |

| Punching pierce | 120-160times/min |

| Ceiling Tile Type | Swing Down |

Technical Support

Technical Support

KINGREAL is a professional manufacturer of Metal Suspended Ceiling Making Machines in China, We have successfully customized squared ceiling production lines to meet the needs of customers in many countries, including Turkey, the United Arab Emirates, Russia, India and so on.

KINGREAL has a professional technical team with more than 25 years of relevant experience from the drawing design to the manufacturing of machines.

Quality Assurance

Quality Assurance

KINGREAL has passed ISO9000 certification and has the ability of ISO9000 quality system management.

Raw material procurement → production process → assembly → testing → packaging & shipping. Each production step is under strict quality control.