Video Display

Video Display

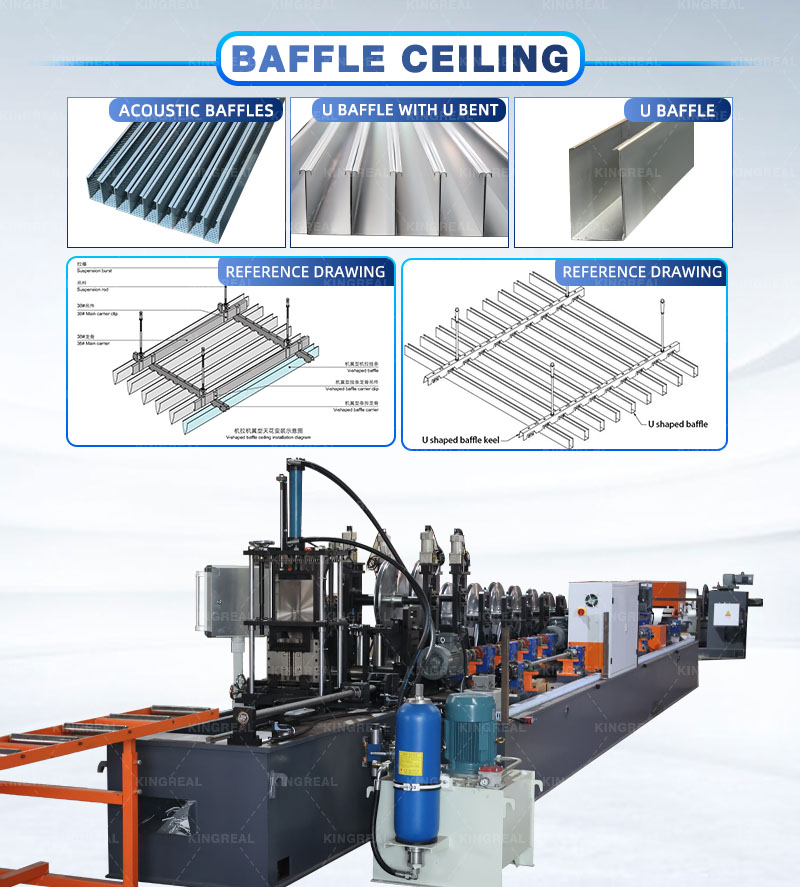

Description of Metal Baffle Ceiling System

Description of Metal Baffle Ceiling System

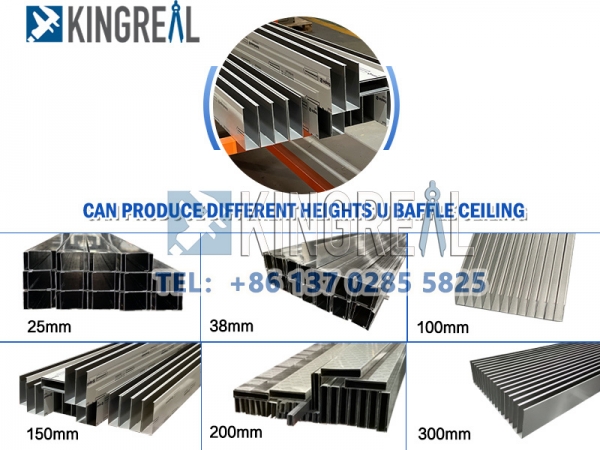

KINGREAL has been engaged in the metal baffle roll forming machine industry for more than 20 years and can provide different metal baffle production solutions, including

1. 150mm/200mm/300mm metal baffle roll forming machine

2. Acoustic baffle ceiling making machine

3. V shape suspended baffle ceiling making machine

4. Metal baffle with u bent making machine

and so on...

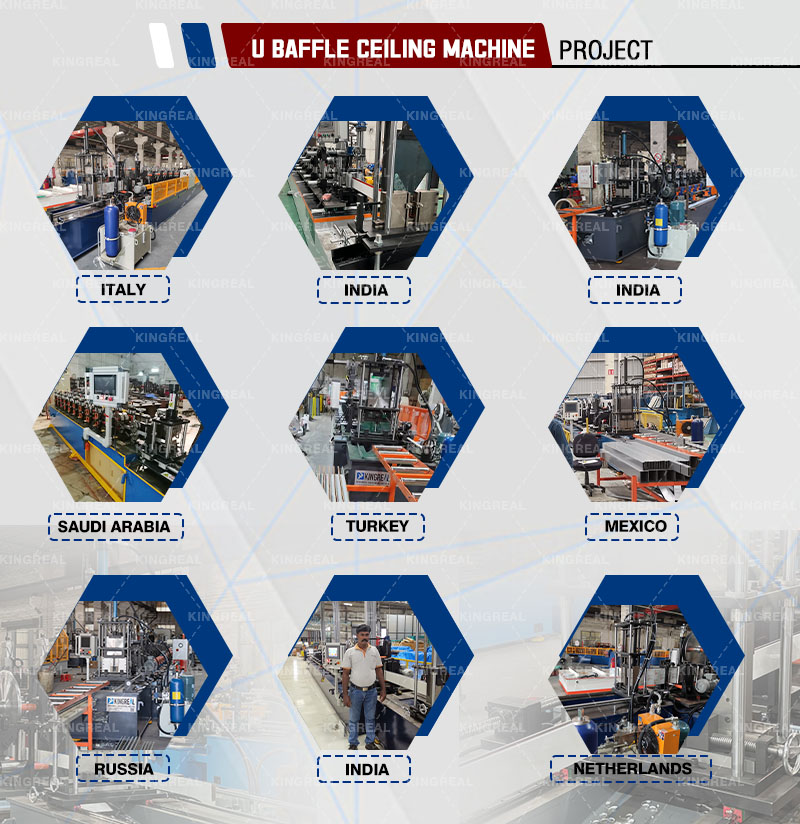

Due to its flexible production characteristics, it is favored by metal baffle ceiling manufacturers and has been successfully exported to Turkey, Greece, Russia, Brazil and other places.

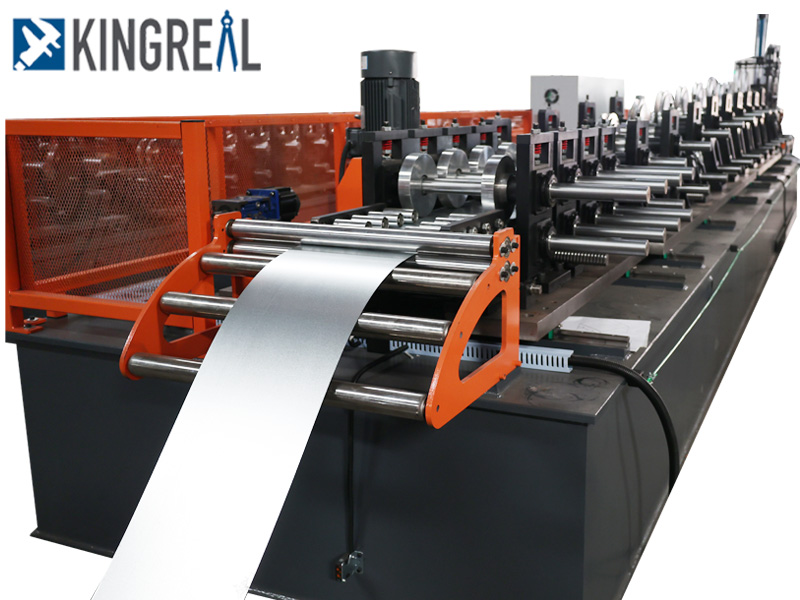

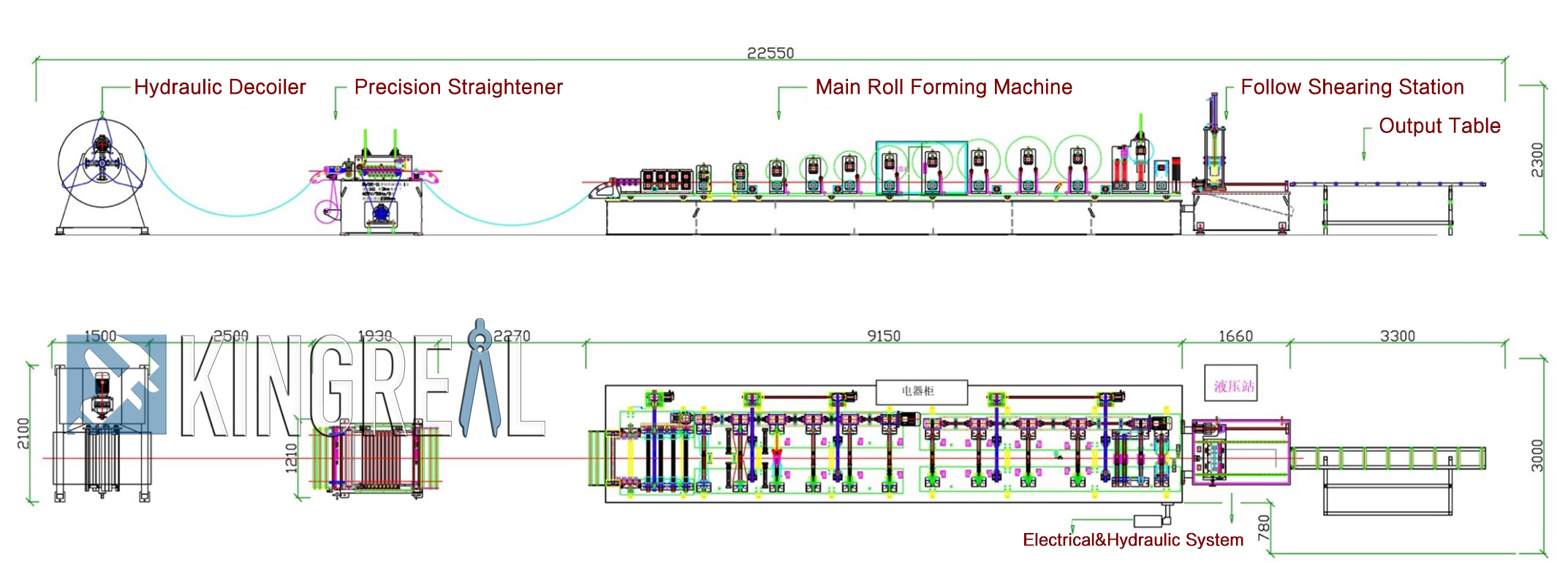

Main Components

Main Components

Decoiler

|

Leveler

|

Main Roll Forming Machine

|

Shearing System

|

Working Process of Baffle Ceiling Roll Forming Machine

Working Process of Baffle Ceiling Roll Forming Machine

Decoiler - Leveler - Main roll forming - Shearing - Output

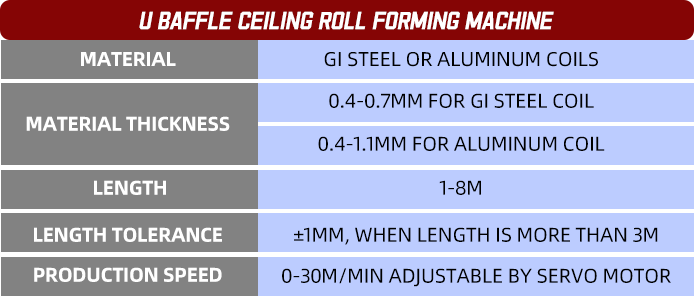

Specification

Specification

Introduction of Different Metal Baffle Ceiling Making Machine

Introduction of Different Metal Baffle Ceiling Making Machine

|

|

|

150mm / 200mm u baffle ceiling making machine

main features:1. It can produce different sizes of baffle ceiling with width (30-100mm) and height (35-200mm). 2. Controlled by PLC, and the imported rotary encoder has automatic length detect. It takes only 1 minute to change from one specification to another. |

300mm metal baffle ceiling roll forming machine

main features:1. Adopting hollow structure to reduce the problem of indentation caused by weight of the rollers. 2. Successful customized projects for Douglas Group, if you have any special u baffle ceiling produstion requirement, welcome to contact us! |

|

|

|

acoustic baffle roll forming machine

main features:1. Hydraulic following shearing station is equipped in the sound baffle ceiling roll forming machine, highly increased the production efficiency. 2. Compatible with pre-painted and pre-perforated raw material coils. |

v shape baffle roll forming machine main features:

1. Forming by high-quality Cr12MoV rollers, which ensures high-precision roll forming. 2. Adopting 21 rollers straightening device, which can realize procise leveling. |

Product Display

Product Display

KINGREAL Successful Projects

KINGREAL Successful Projects

Customer Visit

Customer Visit

It is such a delight to have friends coming from afar. KINGREAL is warmly welcome customers to visit our factory and communicate with us!