Video Display About Linear Strip Ceiling And Carrier Making Machine

Video Display About Linear Strip Ceiling And Carrier Making Machine KINGREAL Successful Cases in Global

KINGREAL Successful Cases in Global |

|

Description Of Linear Strip Ceiling And Carrier Making Machine

Description Of Linear Strip Ceiling And Carrier Making Machine Linear Strip Ceiling Making Machine

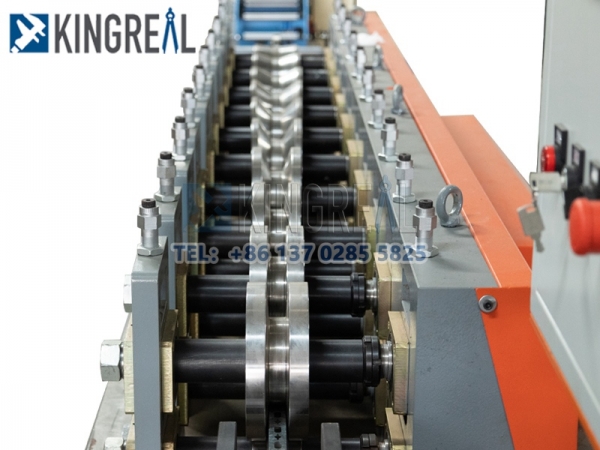

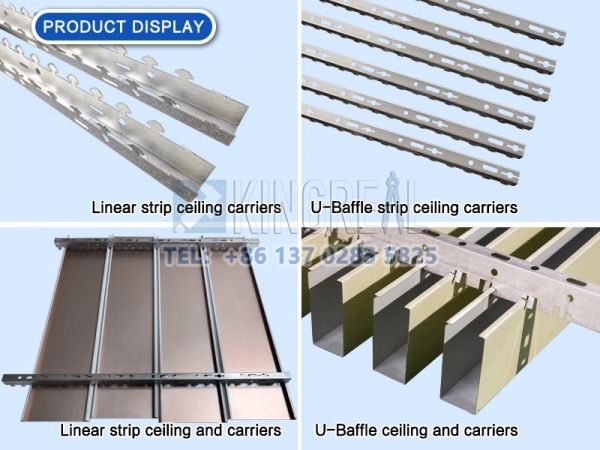

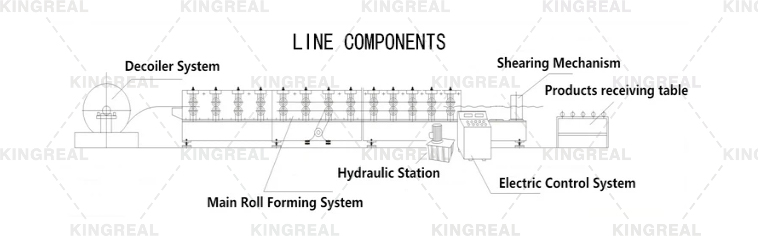

Linear Strip Ceiling Making Machine| KINGREAL Full-Automatic Metal Linear Strip Ceiling Making Machine is a fully computer controlled type, which can automatically produce different shapes of metal strip ceilings, including G/S/R/B/C shapes linear strip ceilings. Components of this line: Hydraulic Decoiler, Precision Straightener, Main Roll Forming Machine, Hydraulic Follow Shearing Station, Product Output Table and Electrical Control System. |

|

| Raw materials | Pre-painted Aluminum |

| Ceiling sizes | 75mm -300mm according with different design |

| Ceiling length | Set on touch screen |

| Maximum forming speed | 10-60 m / min for different products design |

| Roll Forming stands | 15-21 Rollers station according with clients’ request |

| Ends bending | Depends on customer’ request |

| Machine Power | ~ 15 KW |

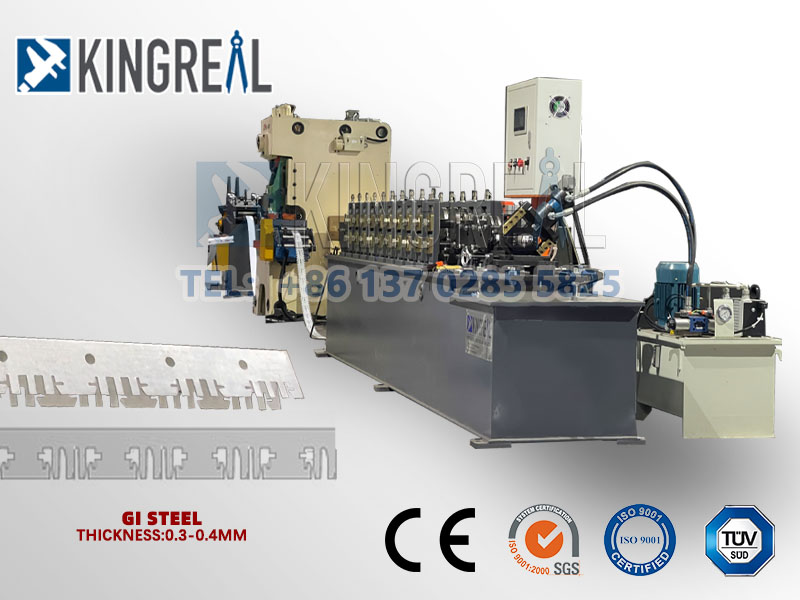

Metal Strip Ceiling Carrier Roll Forming Machine

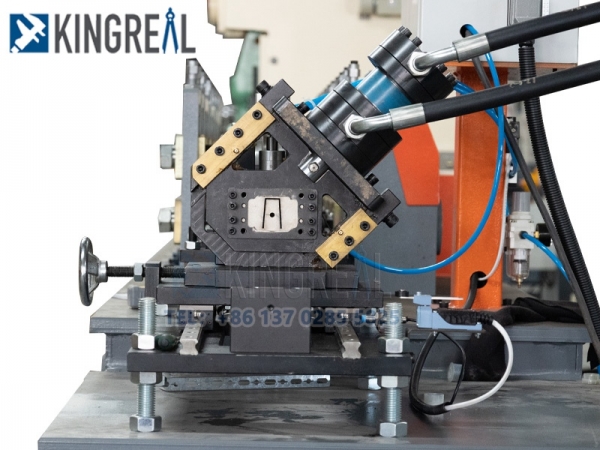

Metal Strip Ceiling Carrier Roll Forming Machine| KINGREAL Linear Metal Ceiling Carrier Making Machine can produce different shapes and different widths of linear ceiling panels and carriers of corresponding sizes, which are used to install the suspended linear ceiling. Components of this line: combine decoiler and straightener, main roll forming machine, punch press, auto shearing station, output tables. |

|

Specification

| Raw materials | Galvanized steel strip |

| Carrier sizes | According with customers’ drawing |

| Maximum forming speed | 20 m / min |

| Roll Forming stands | 10-15 Rollers station |

| Machine Power | ~ 20 KW |

Advantages of Linear Strip Ceiling And Carrier Making Machine

Advantages of Linear Strip Ceiling And Carrier Making Machine

Working Process of Linear Strip Ceiling Production Line

Working Process of Linear Strip Ceiling Production Line

Uncoil → Material Straightening → Punching Station →Continuously Cold Roll Forming → Auto Shearing → Products Output

Application of Linear Strip Ceilings

Application of Linear Strip Ceilings

Different Combination Suspended Ceiling And Carrier Production Solution

Different Combination Suspended Ceiling And Carrier Production Solution

U Baffle Ceiling System

|

|

|

U Baffle Ceiling Making Machine can produce different heights of metal baffle ceiling, including 150mm / 200mm / 300mm, other sizes can be customized. Main Features: - The width of the metal baffle ceiling can be adjusted automatically - Adopt following shearing, greatly increase the production speed |

U Baffle Ceiling Carrier Roll Forming Machine

U Baffle Ceiling Carrier Roll Forming Machine is used for producing a carrier to install a metal baffle ceiling. Main Features: - The metal punching machine adopts a pneumatic brake system makes the perforation more accurate and stable - Can produce u baffle ceiling carrier and linear strip ceiling carrier in one machine |

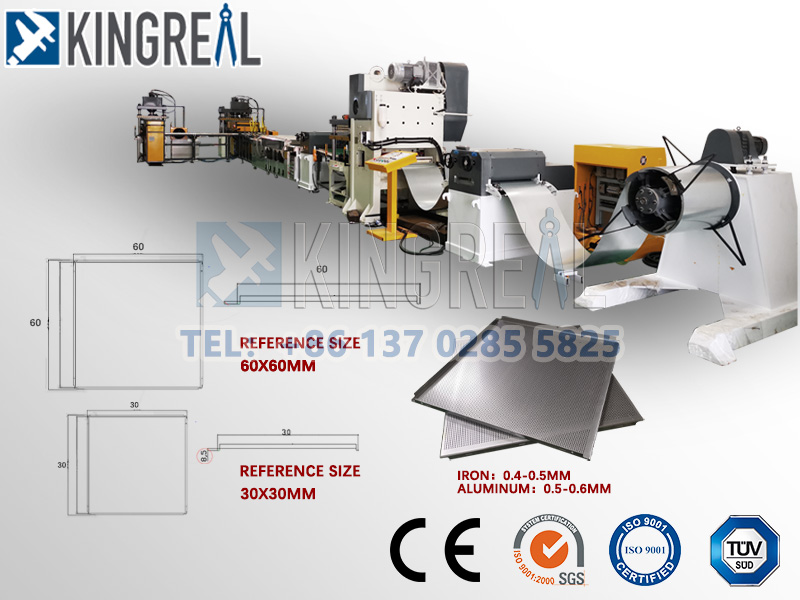

Metal Ceiling Tiles System

|

|

|

|

Metal Ceiling Tiles Making Machine can produce different sizes and different types of metal ceiling panels. The common sizes include 30*30cm / 60*60 cm / 60*120 cm. The common types include lay in ceiling tiles and clip in ceiling tiles. Can be customized according to your production needs. Main Features: - Flexible production solutions and machine configurations, all determined by your metal ceiling panel production needs - Highly automated, only a small amount of manpower is needed from unwinding to finished metal ceiling panel output |

Metal Ceiling Tiles Carrier Roll Forming Machine

KINGREAL can provide different types of metal ceiling panel carriers according to your production needs. The common types include T bar grid, spring tee and A type carrier. Main Features: - Adopt hydraulic follow shearing station, ensures precision and neatness in the cutting of the ceiling tile carrier - The specifications can be easily set in the touch screen operating system with multilingual support |

How KINGREAL Ensures The Quality of Manufacturing Machine

How KINGREAL Ensures The Quality of Manufacturing MachineEstablish a strict quality system

In order to better control the quality of the machine, Kingreal has established its own factory and technical team. KINGREAL has established standardized work process standards to ensure that the machine maintains a high standard from manufacturing to debugging. From the selection of parts to the debugging of the machine, our team works strictly in accordance with the standards. To provide customers with professional and high-quality machines, in order to fulfill this promise, KINGREAL has subdivided the work into every step.

Quality certified

KINGREAL has passed ISO9000 certification and has the ability of ISO9000 quality system management. It has also passed the international CE certificate certification.

After-Sales Services

After-Sales Services

Services are always highly considered by us, in addition to establishing a complete remote service system, localized after-sales service is also what KINGREAL has been insisting on doing. The global localization service point is under construction.