Video About Metal Linear Strip Ceiling Making Machine

Video About Metal Linear Strip Ceiling Making Machine Different Linear Strip Ceiling Roll Forming Machine

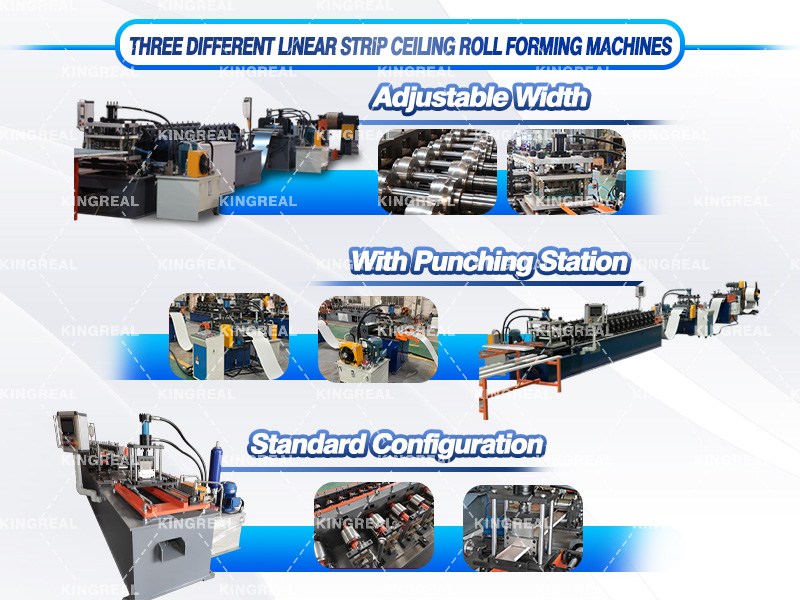

Different Linear Strip Ceiling Roll Forming Machine

Brief Introduction Of Different Shape Metal Linear Strip Ceiling Making Machine

Brief Introduction Of Different Shape Metal Linear Strip Ceiling Making Machine

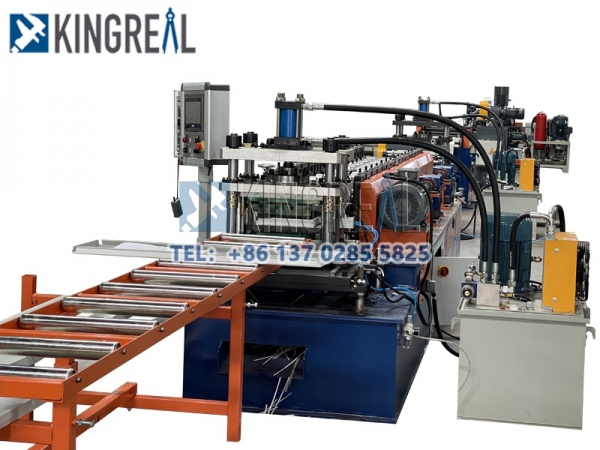

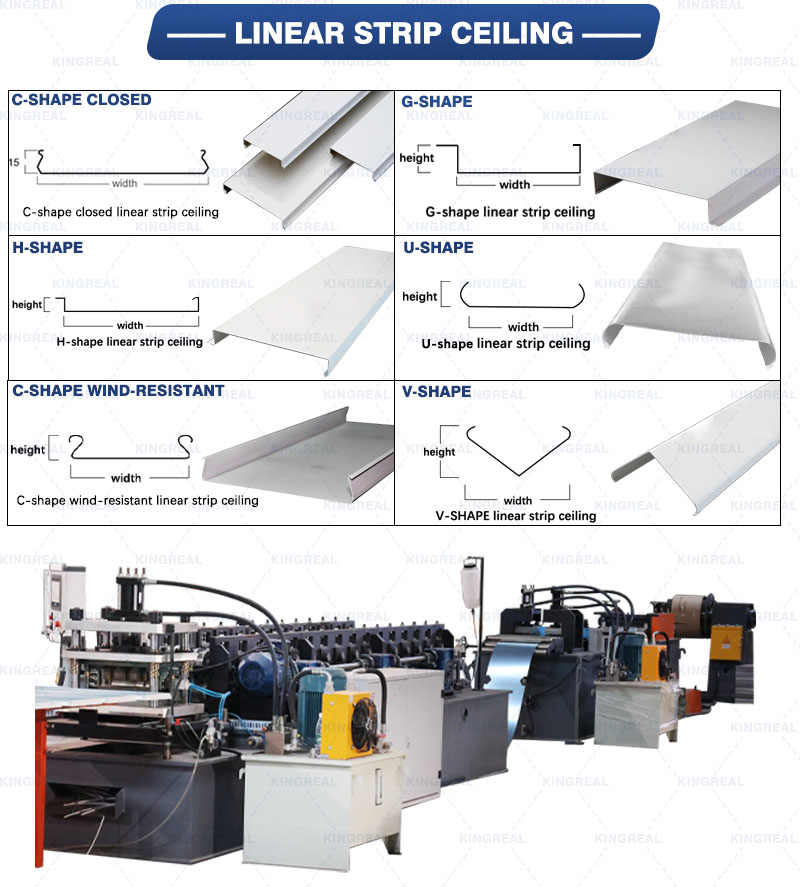

KINGREAL Metal Linear Strip Ceiling Making Machine is full-automatic type with capability of producing different sizes of linear ceiling panels. By switching roller stations, shearing stations and molds, production line can produce C-Shape ceiling strip, G-Shape metal linear, H-Shape ceiling strip, S-Shape metal linear, V-Shape linear strip ceiling and etc..

Kingreal has been deeply involved in the metal linear strip ceiling making machine manufacturing industry for more than 20 years, our strip making machine have been successfully exported to many countries, around the world, including Canada, UAE, Russia, India, etc.. We also can customized manufacturing machine according to your production needs, KINGREAL is literally your first choice of metal strip ceiling production.

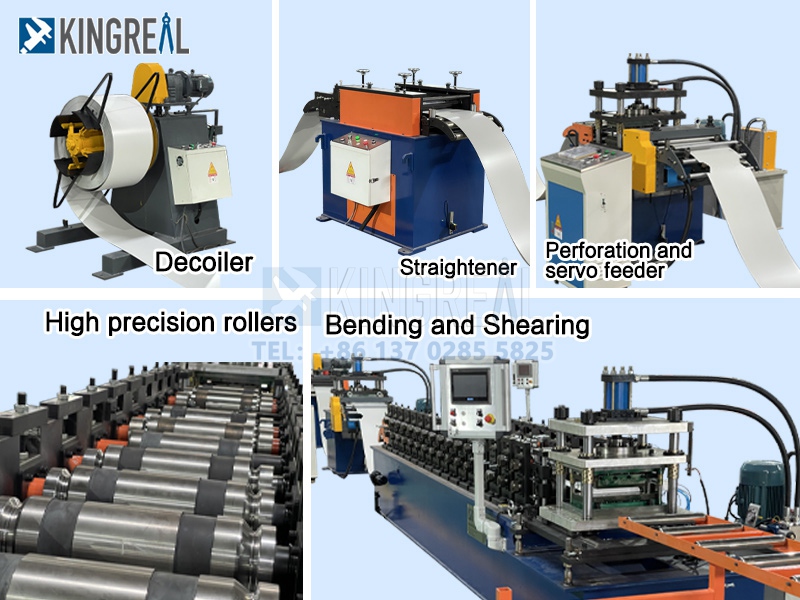

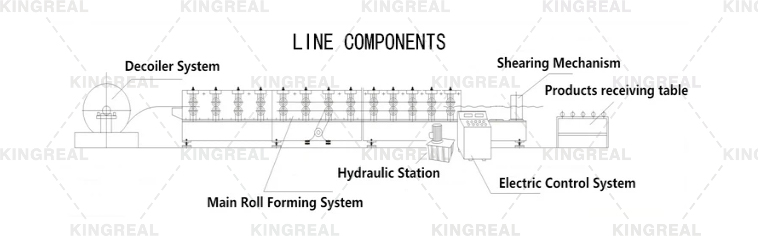

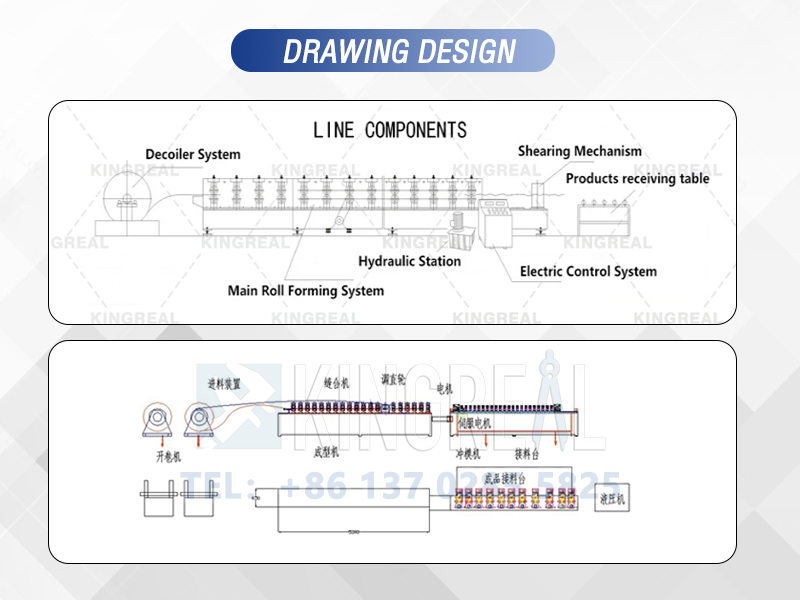

Main components of this production line

Main components of this production line

|

|

|

Working Process of Metal Linear Strip Ceiling Production Line

Working Process of Metal Linear Strip Ceiling Production Line

Hydraulic Decoiler -- Precision Straightener -- Pre-Notching Station -- Main Roll Forming Machine -- Shearing & Bending -- Output Table

Technical Specification

Technical Specification

|

Line structure |

Portal-type frame style, A3 steel |

|

Forming Roller Stations |

12 Stations |

|

Forming Roller shaft |

Φ40mm |

|

Forming rollers |

Cr12, Quenching, hardness HRC56-58º |

|

Hydraulic punching system |

Servo feeding; Holes position tolerance ±0.03mm |

|

Forming Speed |

7-12 meters / min |

|

Main motor |

5.5kw |

|

Material of Sheet |

Soft Quality (Annealed) Galvanized Sheet |

|

Sheet Thickness |

0.3 to 0.5 mm |

|

Cutting mode |

Hydraulic automatic punching and cutting machine |

|

Control Cabinet |

3xAC380v, 50HZ |

|

Main machine sizes (L*W*H) mm |

6000*700 *700 |

Feature of Linear Metal Strip Ceiling Making Machine

Feature of Linear Metal Strip Ceiling Making Machine

|

High Precision Straightener

The machine provides high-precision straightening. To ensure straightness of materials, we doubled the amount of precision rolls, adopting 21 rollers leveler. As a result, finished linear metal ceiling panelss have higher precision. Levelling rollers, which are made of 40Cr round bars, were thermal refined, quenched at high frequency, electroplated twice and accurately ground. They are smooth, without scratches, their hardness is above HRC62, and regulated by 4 threaded rods. |

|

|

PLC Control System This production line is PLC controlled with touch screen display operating systemm achieved high degree of automation. After parameters are input, roller stations will automatically adjust accordingly. The same procedure can be applied in all of our linear strip ceiling production lines, so that clients can flexibly choose their product sizes. The main roll forming machine contains 15 roller stations for cold linear strip forming. |

|

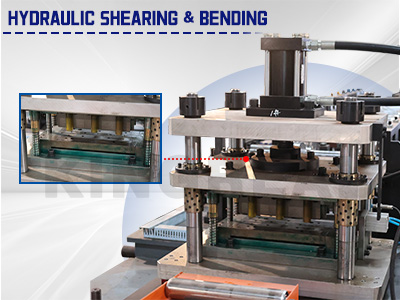

Hydraulic Cutting Station KINGREAL choose high-quality servo motor from YASKAWA for our hydraulic shearing and bending station. It‘s easy to set up length on touch screen operating system, then station will shear product to length accordingly. Shearing speed is 30m/min maximum and adjustable. This station can shear finished linear metal ceiling panels precisely and accurately. |

|

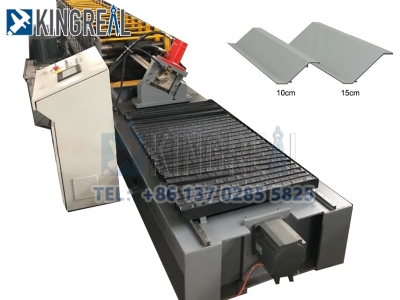

Diverse Linear Metal Ceiling Production Solution

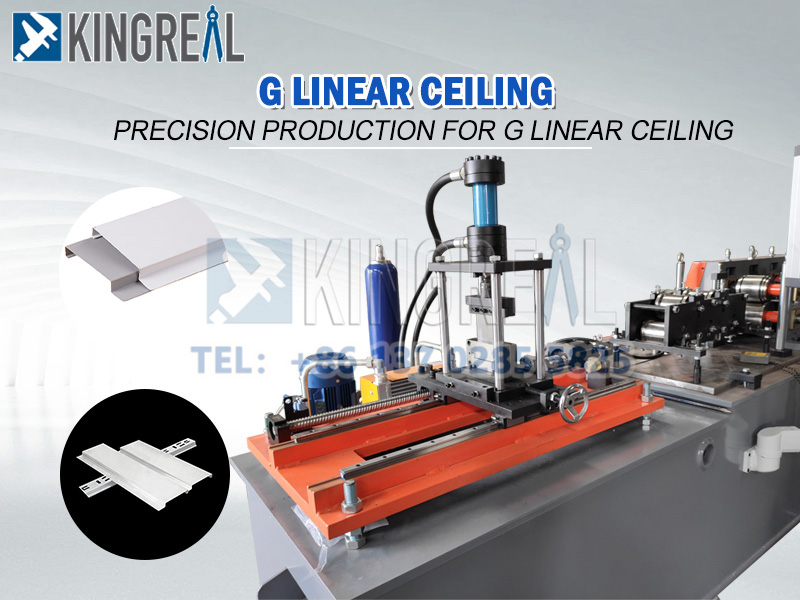

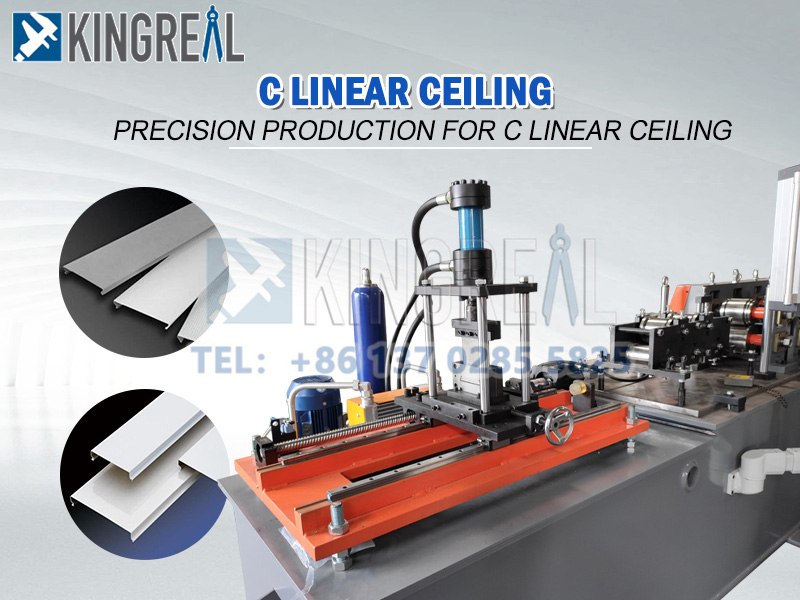

Diverse Linear Metal Ceiling Production SolutionKINGREAL linear metal ceiling making machine adopts advanced technology and can produce linear ceiling panels in various sizes and shapes. The following are common linear ceiling panels types:

G-Shape metal linear

|

C-Shape ceiling strip

|

S-Shape metal linear

|

V-Shape linear strip ceiling

|

KINGREAL can provide customized production services. Just tell us your production needs of ceiling strip and we will provide you with the latest technical solutions and quotations.

Application of Linear Strip Ceiling

Application of Linear Strip Ceiling

Technology Support

Technology Support |

|

KINGREAL in Diverse Exhibition

KINGREAL in Diverse Exhibition