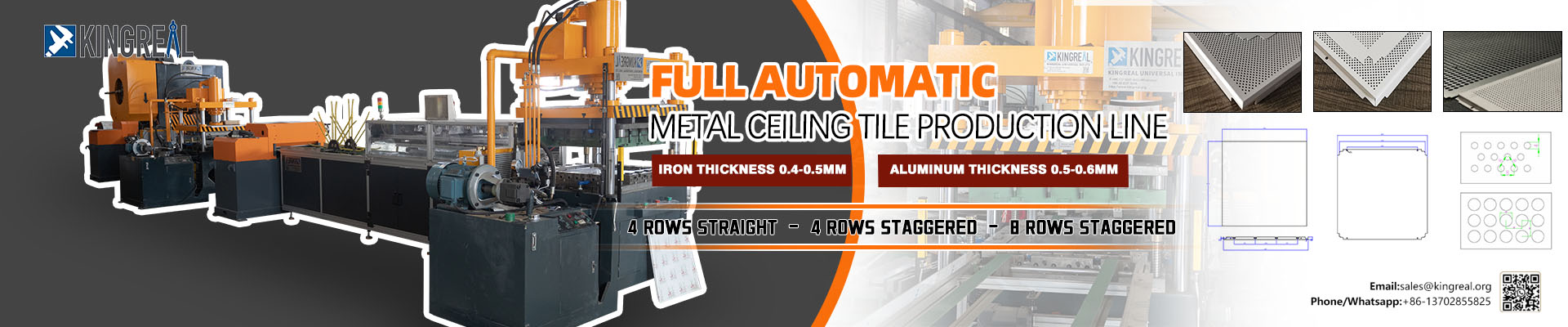

Description Of Hook-On Ceiling Tile Production Line

Description Of Hook-On Ceiling Tile Production Line

KINGREAL Hook-On Ceiling Tile Production Line is design for produce different size hook-on ceiling, which can maintains panel performance and is the ideal solution for a variety of commercial and industrial applications.

A solid, easily accessible ceiling system is provided by hook-on metal ceilings. Black iron is not necessary for heavy-duty extruded aluminum suspension, which is wire-hung. The system complies with CISCA and ASTM requirements.

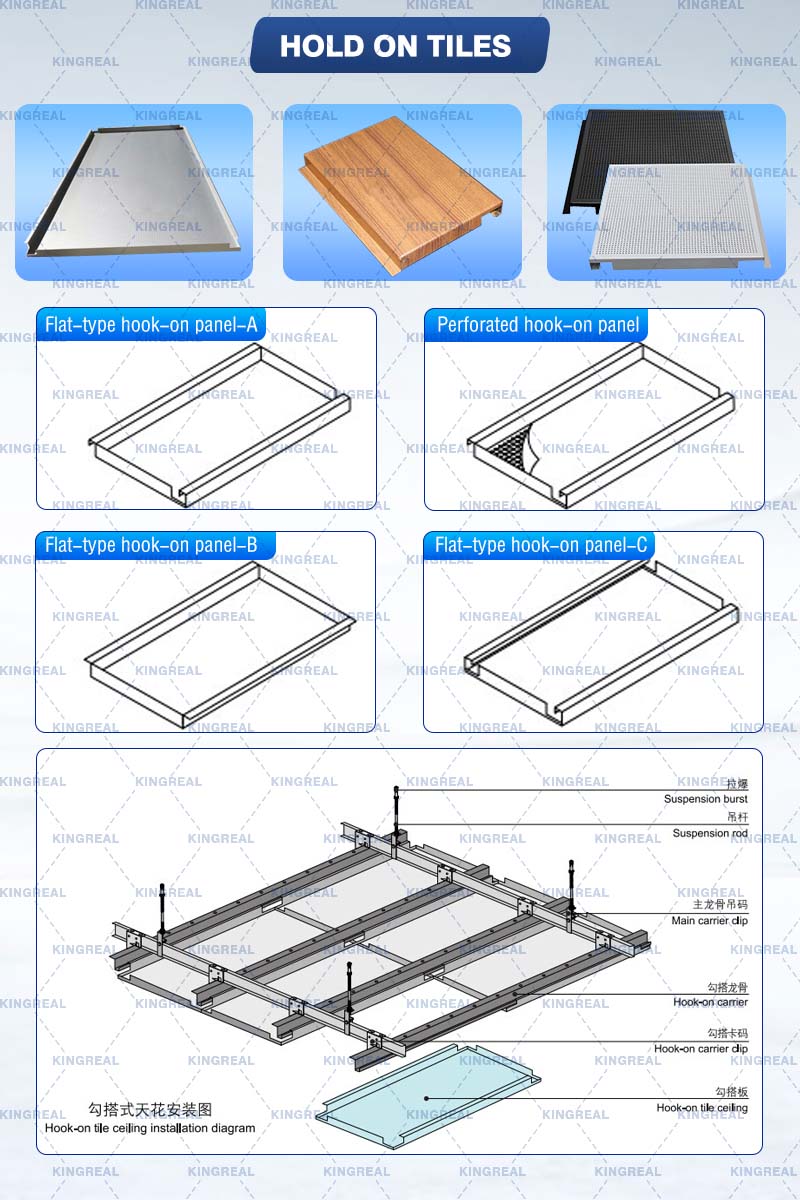

Reference Drawing

Reference Drawing

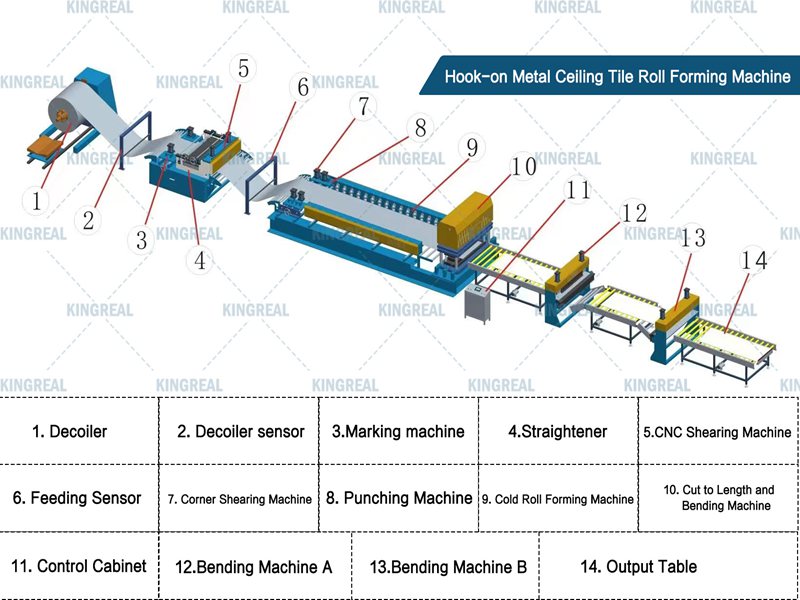

Working Process Of Hook On Ceiling Production Line

Working Process Of Hook On Ceiling Production Line

Strip Pieces Feeding -- Main Roll Forming Machine(Width Adjustable) -- Discharge (Hook) -- Discharge (On) -- Conveying -- Bending Part -- Output Table

Specification Of Hook Ceiling

Specification Of Hook Ceiling

| Panel Material: | Aluminum, Stainless Steel, Steel and so on |

| Ceiling Width: |

3‘-0" or more Panels can be up to 8 feet long. |

| Surface: |

Rectangle and square are typical shapes. |

| Hook On Ceiling Tile Size: |

600*600mm, 600*1200mm, 800*800mm, 1000*1000mm Width from 300-1000 Length from 200-2000mm Thickness: 0.5-1.0mm |

Advantage Of Hook On Ceiling Production Line

Advantage Of Hook On Ceiling Production Line

Structure of a Sturdy Roll Forming Machine

The line‘s fundamental panel is built of excellent steel and has a superb 30mm thickness. It was additionally divided by various servo motors. Please take note that this panel can guarantee machine durability throughout prolonged use.

Auto-Adjustable Width

Yaskawa well-built servo motors were used to power this assembly line and place the roller stands precisely. The Acoustic Baffle Ceiling Machine is also computer controlled, so adjustments only require input to the system; the remainder will be completed by the machine itself.

Product Display:

Product Display:

FAQ:

FAQ:

Q1:How long will you send the proposal and offer?

A1:We will need about 3~7 days to design the proposal upon collecting all details of the ab- ove mentioned info necessary.

Q2:How long do you need to install and commissioning the machine line?

A2: Usually one week for installing and teaching workers about how to operate.

Q3:How many people will come to install and commission the machine line?

A3: Usually 1 engineer is enough to do all the things. All his expense during this travel will be paid by buyer accordingly.

KINGREAL Factory

KINGREAL Factory

KINGREAL MACHINERY is one of the most professional metal sheets forming machines supplier in China.

We have a team of experts who have over 25 years of experience in Full-Automatic Metal Ceiling Tiles Production Lines with Fleece Sticking, Semi-Automatic Metal Ceiling Tiles Production Lines, High-Speed Metal Sheets Perforating Lines, A-shape/Triangle Roll Forming Carriers, Tee Grids Ceilings Production Lines, Independent Fabric Sticking Machines, etc.

At present, KINGREAL has successfully transported the machine production to all over the world, including the United Arab Emirates, India, Russia, Saudi Arabia, Egypt, Pakistan and other countries

Our Customers

Our Customers

How To Order?

How To Order?