Video Display

Video Display Description of HVAC Volume Control Damper Production Line

Description of HVAC Volume Control Damper Production Line The HVAC volume control damper is a device used to adjust the amount of fresh air in the ventilation system. It plays a key role in ventilation and air conditioning systems. The HVAC volume control damper adjusts the air circulation through precise adjustment and control, thereby achieving control and regulation of the indoor environment. The HVAC damper system involves many equipments, and the performance requirements of the machines are also different, so the production capacity and technical capabilities of the HVAC rectangular damper manufacturers are required to be high. KIGNREAL‘s technical team has developed a complete HVAC rectangular damper production line through continuous technical research and development and machine debugging, and can provide suitable technical solutions according to the different HVAC damper production needs of customers. KINGREAL is committed to providing you with excellent performance damper equipment. Our goal is to help you increase production capacity and increase benefits.

The volume control damper production line provided by KINGREAL includes vcd frame machine, TDC flange making machine and hvac rectangular damper blade machine. Different components are responsible for different processes, which can eventually be combined into a complete HVAC volume control damper.

Complete Volume Control Damper Production Solution

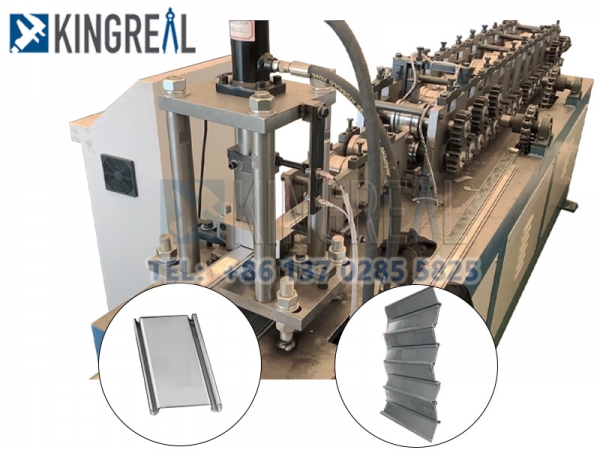

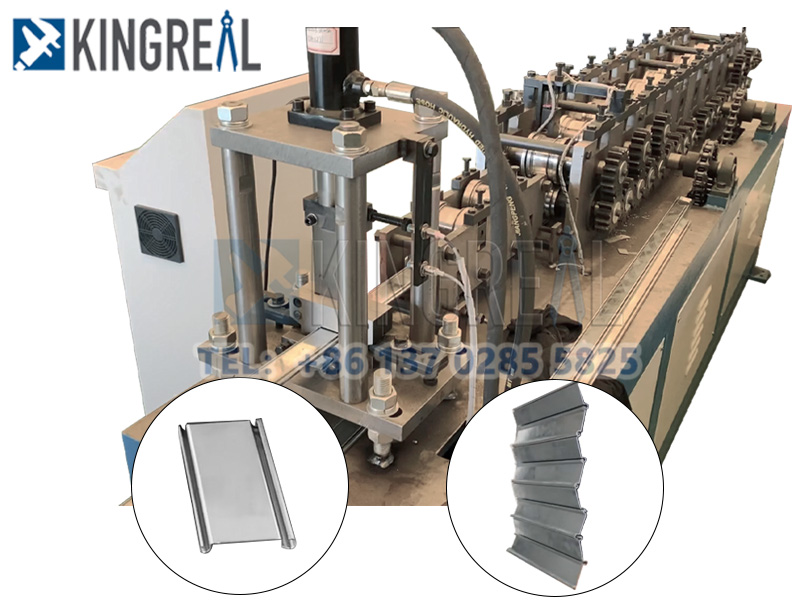

Complete Volume Control Damper Production Solution  VCD Frame Roll Forming Machine

VCD Frame Roll Forming MachineThis vcd frame machine is used to produce the outer frame of the vcd dampers without flanges, i.e. flat surfaces. It has a fully automated production mode, requiring only a small amount of manual labour, which ensures accurate production. The raw material, size and punching pattern of the vcd frame can be adjusted according to your production needs.

* Working process *

Hydraulic Decoiler -- Precision Leveler -- Punching Station -- Main Roll Forming Machine -- Hydraulic Bending Cutting Station -- Output Table

* Main Features *

1.Automatic production mode

The volume control damper frame roll forming machine is equipped with a PLC control system and adopts a fully automatic production mode. You only need to set the relevant parameters on the operating table to perform automatic production as required. From unwinding, roll forming, cutting, to finished vcd frame output, no extra manual operation is required. This not only saves labor costs and improves production accuracy, but also effectively reduces the generation of waste, which helps companies improve their efficiency.

2.Precise Leveling

KINGREAL equipped a precise 9 rollers leveler to straighten the metal coil before main roll forming. The leveling roller is made of GCR15 material after heat treatment, with chrome-plated surface, high hardness, wear-resistant and won‘t hurt the surface of metal coil. After the precise leveling machine to straighten the metal coil greatly improves the flatness of the finished plain volume control dampers.

3.Integrated bending

After the hydraulic cutting process, the semi-finished HVAC volume control dampers will be automatically sent to the bending device for bending, without the need to purchase additional bending machine or manual bending. HVAC volume control damper frames are connected by riveting technology without welding.

* Specification *

| Raw materials | 1.0-1.5mm mild steel(Q195,Q235) |

| Raw material ID | 450-520mm |

| Max. raw material weight | 5tons |

| Max. materials width | 400MM |

| Products sizes | According with customers‘ drawing |

| Maximum forming speed | 0-10 m / min |

| Machine Power | ~ 35 KW |

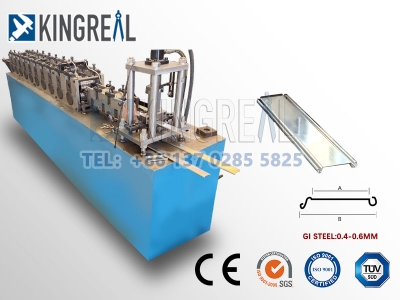

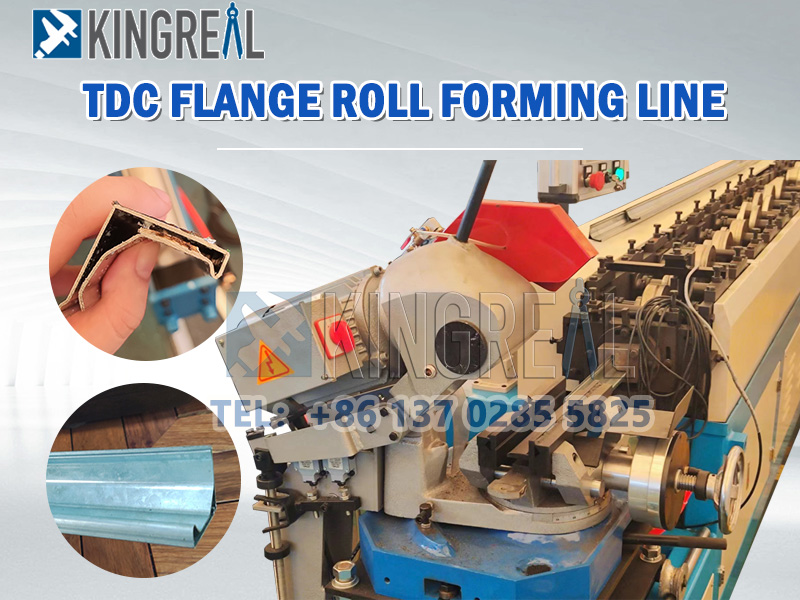

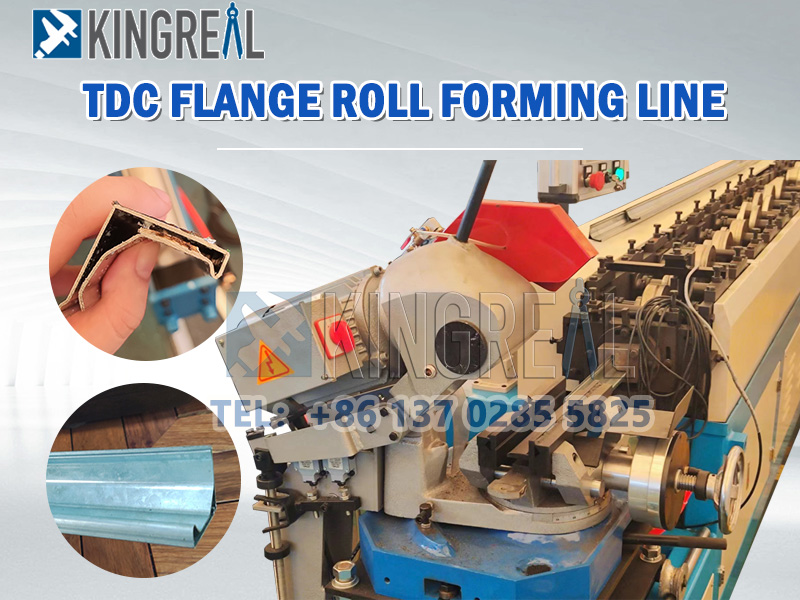

TDC Flange Making Machine

TDC Flange Making MachineTDC flange is the most widely used flange on volume control damper, with advantages such as good sealing and compact connection structure. KINGREAL TDC flange roll forming machine adopts fully automatic production mode, and the cutting system can achieve non-stop fixed-length cutting, saving your production time and effort.

* Working process *

Decoiler -- Leveler and Feeding Guide -- Main Roll Forming -- Cutting

* Main Features *

1.Strong compatibility

In addition to being compatible with different raw materials, the TDC flange making machine can also produce flanges of different shapes, sizes and thicknesses. The main forming roller is made of high-hardness material, and the production error is extremely small. Different types of flanges bring different sealing effects, KINGREAL can provide a suitable TDC flange making machine solution according to your production requirement.

2. The cutting system is equipped with lubricating oil

The cutting system of the TDC flange roll forming machine is equipped with a lubricating oil device, which can extend the service life of the cutting blade, eliminating the need to frequently replace the cutting blade, allowing the TDC flange machine to achieve continuous cutting production without interruption.

* Specification *

* Specification *

| Raw Material | GI Steel, stainless steel and etc. |

| Coil Width | Max. To 89mm |

| Production Speed | 0-10m/min |

| Material Thickness (mm) | according to customer’s need |

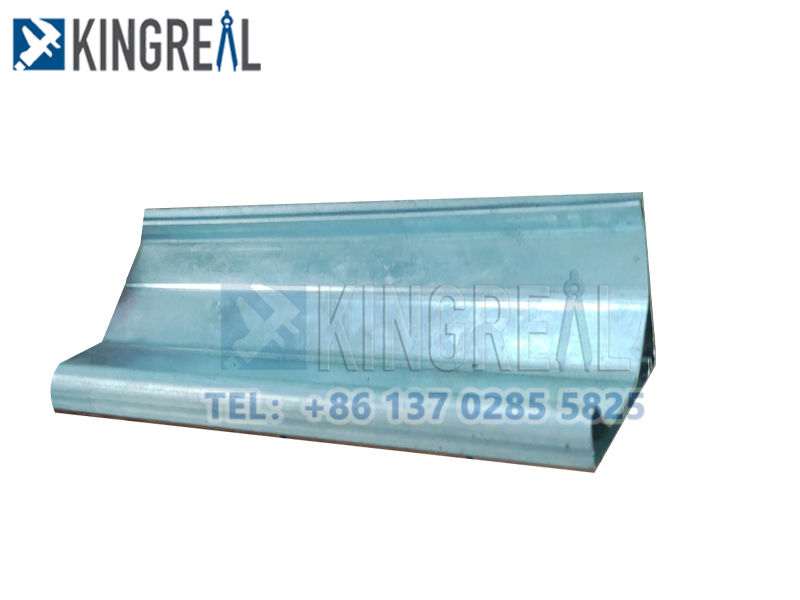

HVAC Rectangular Damper Blade Making Machine

HVAC Rectangular Damper Blade Making MachineThe volume control damper blade is an important part of the hvac vcd system. KINGREAL hvac rectangular damper blade roll forming machine adopts an automated production mode with strong compatibility. It can be compatible with different raw materials and product sizes, which helps you flexibly adjust production.

* Working process *

Decoiler -- Feeding Guide Device -- Main Roll Forming Machine -- Hydraulic Cutter -- Output Table

Main Features:

1.Flexible production

KINGREAL hvac rectangular damper blade roll forming machine is compatible with a variety of metal raw materials, and you can produce VCD damper blades of various materials on one machine. If you need to produce VCD damper blades of different sizes, you only need to adjust parameter settings.

2. Two cutting methods are available

There are two ways to cut the hvac rectangular damper blade: using a hydraulic cutting machine or a punching machine. Both cutting methods can ensure the flatness of the cut surface, and customers can choose according to specific production needs.

* Specification *

| Power | 380V, 60Hz, 3 phase |

| The width of coil | 70-350mm |

| The thickness of material | 1.6mm |

| Length of product | ≦1200mm |

| Total power | about 12kw |

| Line speed about | 18m/min(Not included cutting time) |

Custom HVAC Volume Control Damper Production Line

Custom HVAC Volume Control Damper Production LineDue to the contemporary demand for ventilation system equipment, there are many ways to produce HVAC volume control damper frames, TDC flange and damper blades. In order to meet the general HVAC volume control damper production needs, KINGREAL continues to innovate manufacturing technology and polish every technical detail. Whether it is a vcd frame machine, TDC flange roll forming machine or a volume control damper blade machine, KINGREAL can ensure that the functions of the machine can be optimized and bring the greatest benefits to customers. KINGREAL provides customized manufacturing services for customers. You only need to tell us your production needs or send sample drawings, and we will develop a suitable machine production plan for you.

|

|

|

Kingreal‘s Factory

Kingreal‘s FactoryTo integrate R&D, KINGREAL has established our own factory, located in Foshan, Guangdong. In addition to maintaining close contact online, many of our customers also choose to visit our factory to observe the production of machines and communicate with us face to face. We are looking forward to reaching long-term and stable relationships with customers around the world with our professional capability and consistent level of service!