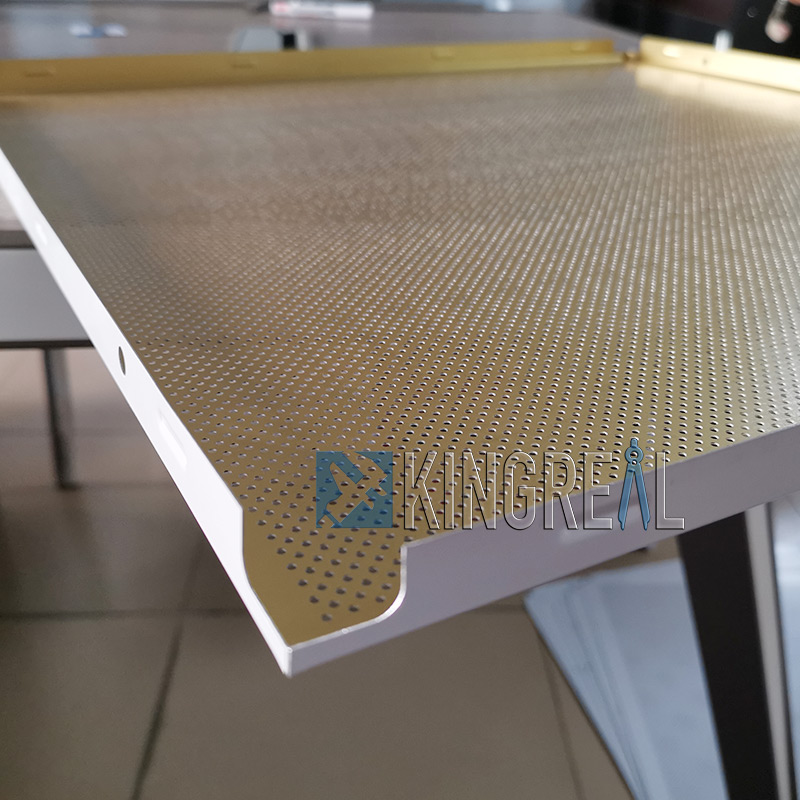

Metal ceiling surface treatment

As we know, the metal ceiling is produced by Square Metal Ceiling Machine. At present, there are three main types of ceiling surface treatment: film coating, rolling coating and spraying, among which the film-coated board is more practical.

Now there are many ceiling surface treatments in the market, also called lamination, but it is a kind of domestic film, and the forming board is called plastic lamination board.

There is also a pearlescent board, the surface looks similar to the film-coated board, but it is not a film at all, it is just adding pearlescent powder to the paint used for spraying in advance during electrostatic spraying.

This kind of board is prone to chromatic aberration, and generally it will change color after two or three years, and the paint will fall off.

Process of spraying the surface of the board

Semi-finished products - degreasing - cleaning - chroming - drying (air drying) - electrostatic powder spraying - curing, cooling - unloading and inspection - packaging and storage.

The surface of the best spraying board in the market is sprayed with "epoxy" electrostatic powder, with adhesion level 1, gloss of 18 degrees, no color difference, no bubbles, no accumulated particles, and weather resistance.

It is worth noting that a good spray plate is passivated before spraying on the surface. Any part of the surface is crossed with a sharp blade to draw a small grid of 1MM*1MM, and it is peeled off with medical tape, and the coating does not fall off. Wash it back and forth 100 times, the surface is not damaged.

Second generation Roller Plate Processing Process

Roller-coated boards have topcoat, primer, and back coat. The back coat mainly plays an anti-oxidation effect and makes it last longer.

Semi-finished products - upper machine - forming - lower parts and inspection - packaging and storage.

The surface of the roller-coated plate is uniform and smooth, without obvious defects such as missing coating, shrinkage holes, scratches, and falling off. However, there are trace defects such as bubbles, pits and inclusions on the surface, which are normal phenomena.

The third-generation film-coated board processing process

The surface treatment and process flow of the film-coated board are the same as those of the pre-coated board, except that the surface layer of the film-coated board is (PVC film).

The surface of the laminated board is firmly pasted, and there are no obvious defects such as wrinkling, scratching, falling off, and missing stickers. However, the surface is allowed to have a small number of micro-wrinkles, bumps and other defects within 0.2MM of the two sides in the width direction.

The above is about the ceiling surface treatment skills. If you want to know more about ceiling products or machines, please visit our official website.