Why degrease sheet metal?

Lubricants and oils are sometimes required when machining sheet metal parts and metals. For example, cooling lubricants are used before turning and milling or forming oils. Decreasing is part of the preparatory surface treatment as grease and oil residues can interfere with further processing steps.

Special solvents, so-called degreasers, are used for this. Degreasing and degreasing by dissolving grease and grease on workpiece surfaces. Degreasing can be carried out in the form of liquid solutions or dry degreasing.

Although lubricants and oils are necessary in certain machining steps, and aid in the forming, turning and milling processes described above. But they have aggravating effects in other process. Among other things, they hinder the application of uniform durable coatings.

Therefore, before spraying and spraying power coatings, the work-piece must be degreased and prepared for spraying.

The same applies to other processes, such as anodized aluminium or joining processes. Last but not least, degreasing may also be a customer request. Therefore, removal of greases, lubricants and anti-corrosion oils may also be useful or necessary without further processing (at the company itself).

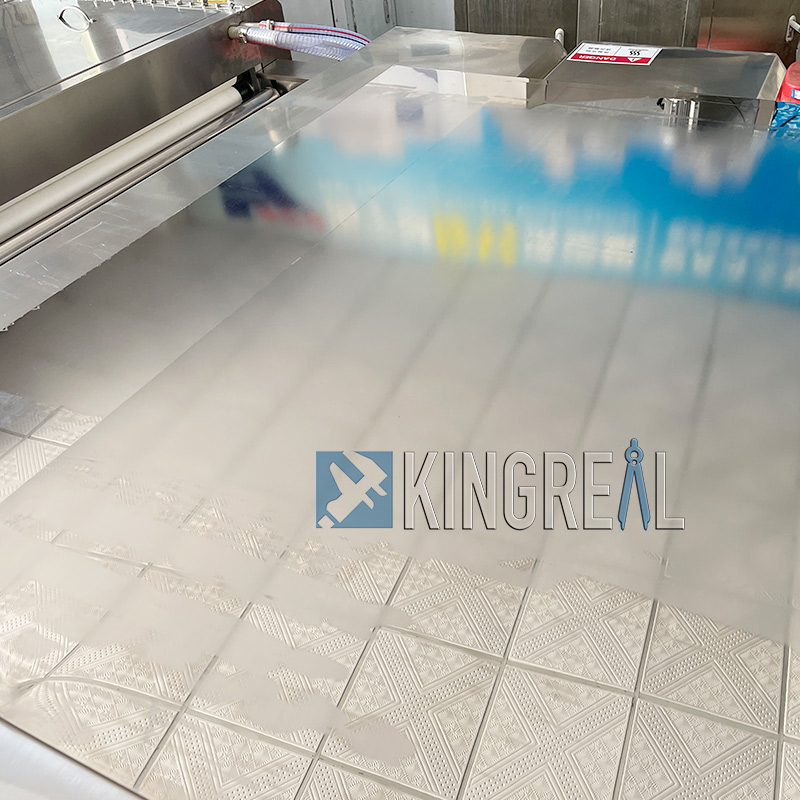

So how to degrease and degrease the metal plate? You can click here to know more about the Metal Sheets Cleaning Degreasing Machine