Video Display

Video Display  Description of Full Automatic Drop Ceiling Tile Production Line

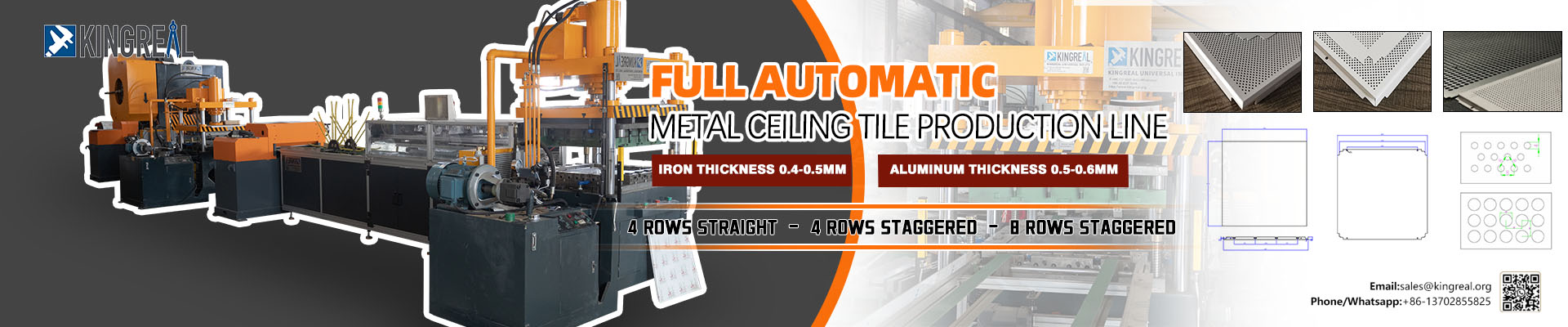

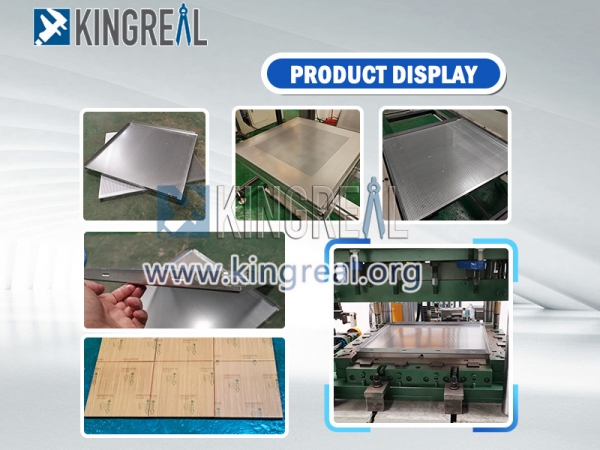

Description of Full Automatic Drop Ceiling Tile Production Line Kingreal Full Automatic Drop Ceiling Tile Production Line is one of our most distinctive products. It is also one of the production lines that ceiling manufacturers purchase the largest quantity from us.

The metal ceiling is leveled by the Kingreal Metal drop ceiling panels production line, which processes metal raw materials through punching, cutting angles, and other crafts, resulting in flat surfaces, neat splicing, adjustable thickness, and simple, easy operation. This ceiling tile perforation line can produce different types of ceiling tiles, such as clip in, lay in and tegular by changing the dies.

The fully automatic ceiling production line by mechanical control system, with high sensitivity, no manual adjustment accuracy. The system runs smoothly, has high output speed, and can effectively avoid the risk of injury.

Composition Of Complete Production Line

Composition Of Complete Production Line | Machine | Features | Amount |

| Decoiler | Hydraulic expansion | 1 Unit |

| Pre-straightener | High-precision 19 Rollers | 1 Unit |

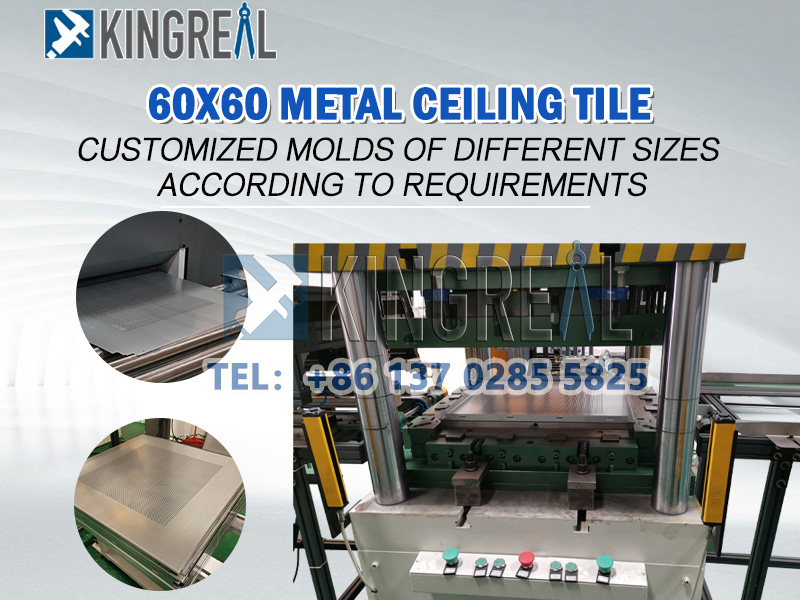

| 125 Tons High-Speed Perforation Press | 125Tons, 100-150 SPM, 2-5PCS tiles/min | 1 Unit |

| NC Servo feeding machine | Yaskawa Servo motor, 3.0KW High accuracy | 1 Unit |

| Hydraulic notching & shearing press | 60tons Hydraulic press, High accuracy | 1 Unit |

| Transmission conveyor | Automatic | 2 Units |

| Precision straightener | High-precision 21 Rollers | 1 Unit |

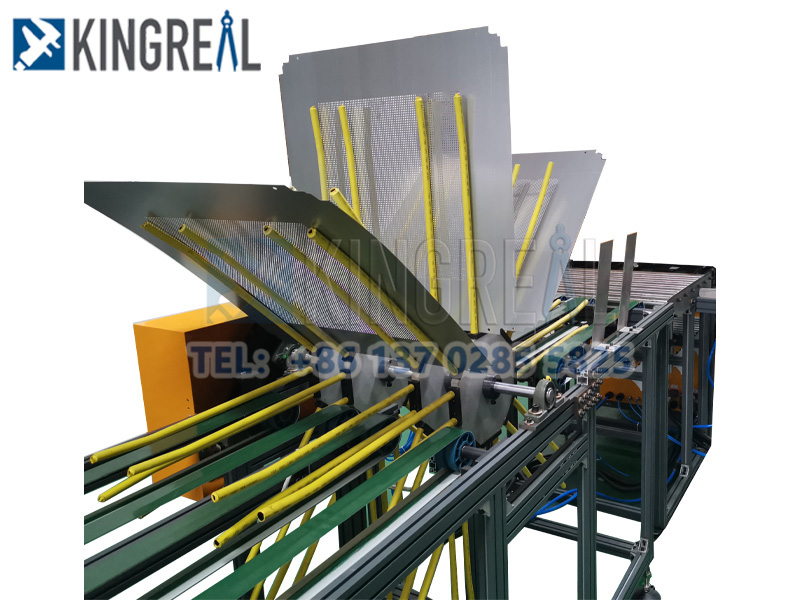

| Automatic tiles flipping machine | For flipping 600*600 tiles 180 degrees | 1 Unit |

| Automatic feeding mechanical arm | For feeding 600*600 tiles to next step production | 1 Unit |

| Hydraulic bending forming press | For bending forming 600*600 tiles | 1 Unit |

| Electric control system | Reliable parts | 1 Unit |

Main Components

Main Components Decoiler -- Straightener -- Servo Feeder -- Perforation Press -- Corner Cutting and Cut-off Press -- Bending Forming Press -- Products Stacking System

|

|

|

| Punching Press | Notching & Shearing Press Machine | Bending Forming Machine |

Optional:

Automatic Cleaning Machine -- Fleece Gluing Machine -- Automatic Turn-over Machine -- Automatic Mechanical Arm -- Re-Straightener

|

|

|

| Degreaser Cleaning Machine | Fleece Gluing Machine | Automatic Turn-over Machine |

Advantages of Main Components

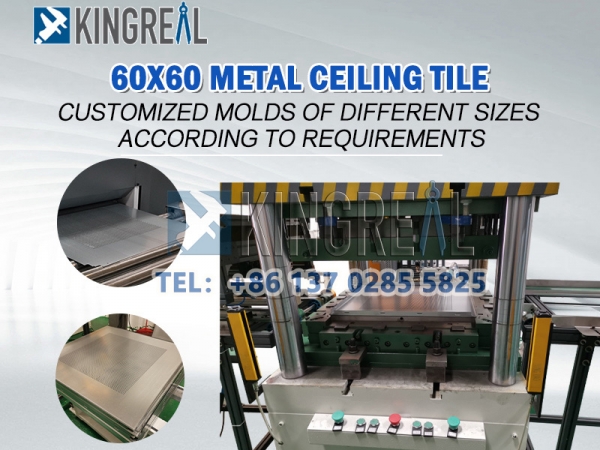

Advantages of Main Components | 1.Perforated Punching Machine (1)Various choices: ①Able to achieve punching requirements of different shapes and sizes; ②Various tonnage presses available(125/160 ton) (2)High speed: The punching speed of KINGREAL standard perforated punching machine can be up to 180 SPM, which can produce an aluminum panel of 5-6pcs/min and an iron panel of 4pcs/min. If you want to upgrade your production speed, kingreal also provides a high-end version of punch press, which can speed up to 240 SPM, can produce an aluminum panel of 6pcs/min and an iron panel of 6pcs/min. |

|

|

2.Precision straightening machine and 2nd straightening machine Kingreal equipped this fully automated ceiling line with two straightening machines. The first one is after the uncoiler, a 21-roller precision straightening machine can highly level the coil before starting the forming operation. The second straightening machine is after corner cutting press. After punching and cutting the corners, the drop ceiling panels tend to bend easily, so the second straightening machine is very important for the quality control of the metal ceiling tile panels. |

| 3.Hydraulic Bending Forming Press (1)Fast and safe, with less material waste; (2)Manual operation:15PCS/min; automatic bending 10PCS/min (3)Suitable for bending and forming of square metal ceiling tiles of different sizes (4)By replacing different bending mold sets, can produce clip-in suspended ceiling tile and lay-in suspended ceiling tiles. |

|

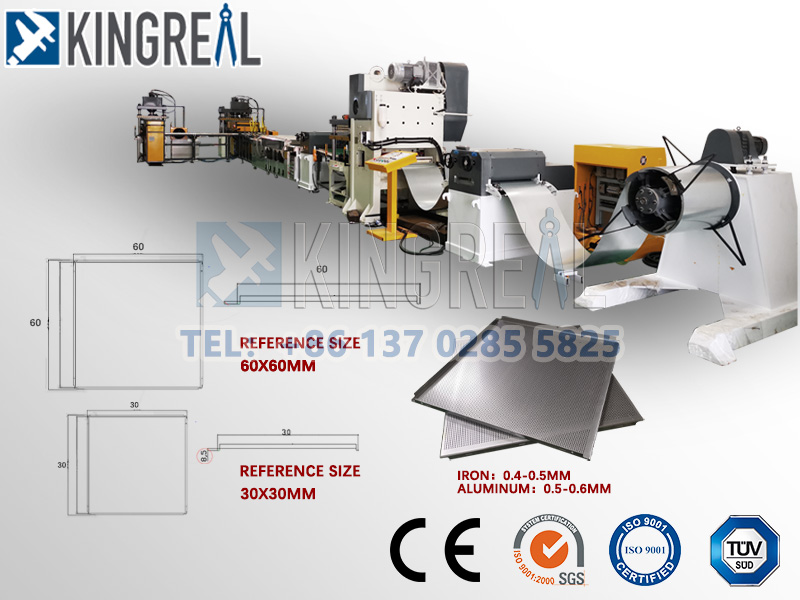

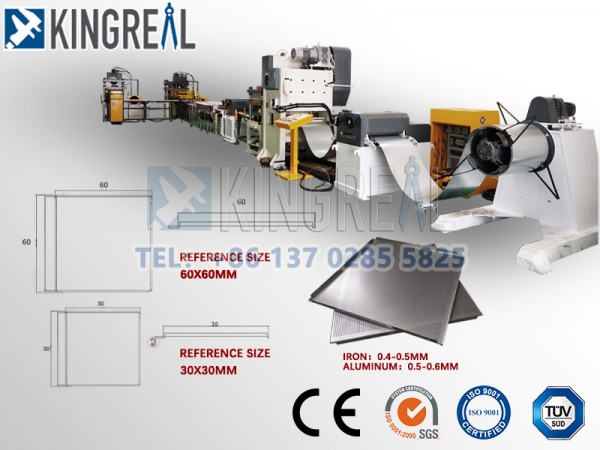

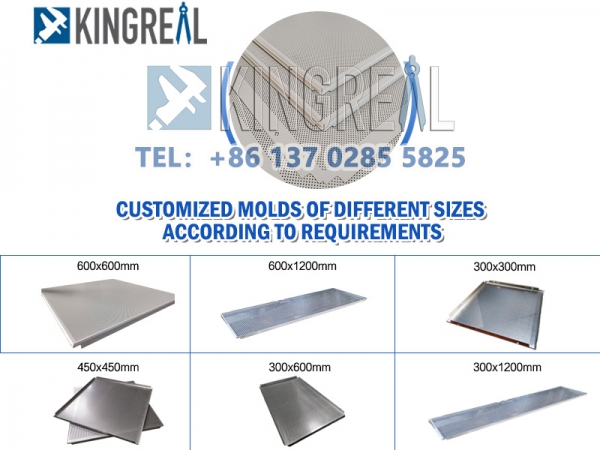

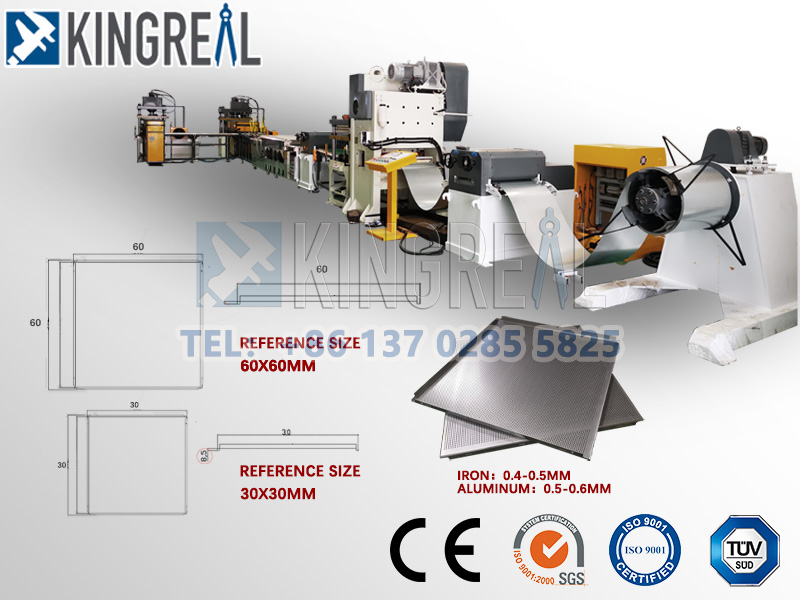

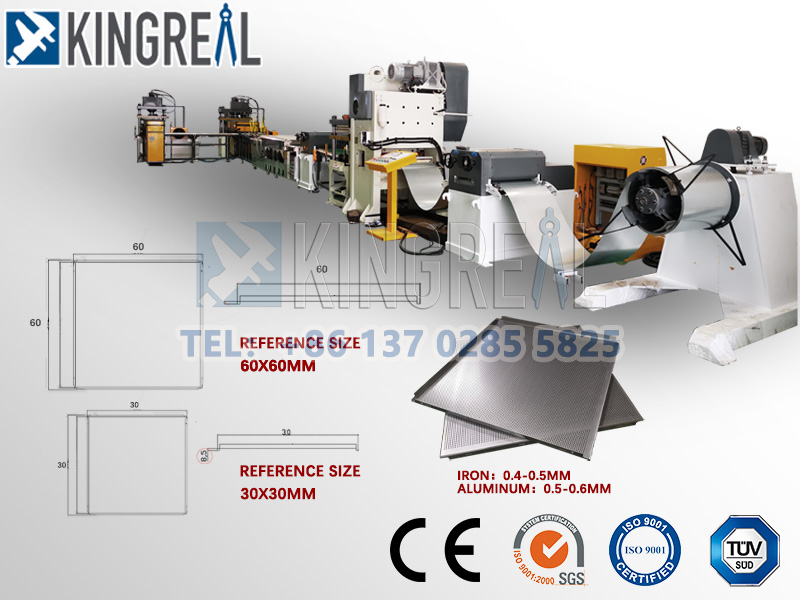

Produce 2 Size of Drop Ceiling Tile Easily

Produce 2 Size of Drop Ceiling Tile Easily 600*600mm and 300*300mm are the most common size in the drop ceiling planks market and are also KINGREAL 2 best-selling drop ceiling panels production lines. In order to adapt to the rapid growth in market demand for these two sizes of drop ceiling panels and to facilitate the production of metal ceiling manufacturers, KINGREAL combined two metal ceiling production lines as one line.

One metal ceiling tile production line can produce 2 different sizes of metal ceiling tile panels, including 300*300mm and 600*600mm. You just need to change the punching mold and corner cutting mold, 2 different sizes of suspended ceiling tiles can be produced easily.

KINGREAL Drop Ceiling Tile Production Line Successful Projects

KINGREAL Drop Ceiling Tile Production Line Successful Projects

Why Choose Kingreal?

Why Choose Kingreal?Expert Technical Support

KINGREAL excels in fully automated processes and precision forming techniques. Our metal ceiling manufacturing equipment is designed to deliver rapid production while ensuring consistent quality and accuracy.

Extensive Production Experience

With over 25 years of experience in drawing design and machine manufacturing, KINGREAL boasts a highly skilled technical team. As a leading manufacturer of metal ceiling production machinery, we have successfully customized ceiling production lines for clients across numerous countries, including Turkey, UAE, Russia, and India.

Kingreal Factory

Kingreal Factory To integrate R&D, KINGREAL has established our own factory, located in Foshan, Guangdong. In addition to maintaining close contact online, many of our customers also choose to visit our factory to observe the production of machines and communicate with us face to face. We are looking forward to reaching long-term and stable relationships with customers around the world with our professional capability and consistent level of service!