Why does the hydraulic pump of a fully automatic hydraulic press leak?

Time:2021-03-11

Views:3054

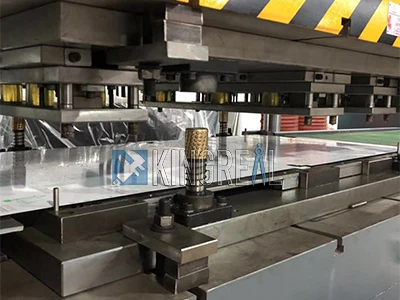

The part of the hydraulic pump of the fully automatic hydraulic press that constitutes the sealed working space must move relatively, so there is a cooperation gap. Because there is a pressure difference between the pump chamber and the booster chamber, the cooperation gap will inevitably leak, and the leak will affect the function of the hydraulic pump. The pressure oil in the oil chamber of the external hydraulic gear pump mainly leaks into the low pressure chamber in three ways.

(1) The leakage of the internal trap and the radial clearance of the tooth top of the hydraulic pump body. Because the rolling direction of the gear is opposite to the leakage direction, and the passage from the pressure chamber to the suction chamber is longer, the leakage is relatively small, accounting for about 10% to 15% of the total leakage.

(2) Leakage of tooth surface clearance. Due to the poor contact in the width direction of the teeth, the tooth profile error forms a gap, so a leak is formed between the oil pressure chamber and the oil suction chamber, and the amount of leakage in this part is very small.

(3) Leakage of gear end face clearance. The gap between the gear end face and the front and rear covers is large, and the oil seal in the gap is long and dirty, so the leakage is large, accounting for about 70% to 75% of the total leakage.

It can be seen that the leakage of the hydraulic gear pump is very large. Its extra work pressure is not high. In order to increase the extra pressure of the gear pump and ensure a higher volume power, the first thing to do is to reduce the leakage along the end face gap.

When using a fully automatic hydraulic machine, check whether the oil pump, control valve and pressure gauge are normal, and whether the oil temperature is within the allowable range; check whether the mold is broken and whether the fastening screw is loose; turn on the power switch and start the cooling cycle motor; start the main oil pump motor ; Check the oil level of each oil tank, check each oil circuit and hydraulic pipe for oil leakage, and check whether the connections are loose; check the deflection or stop and stop of the pressure gauge and pressure indicator of the fully automatic hydraulic press, and check the equipment immediately Extra pressure, and do not exceed the limit value during operation; adjust the operation method switch to the "0" position, perform manual operation, check whether the upper and lower limit switches of the movable beam are safe and reliable, whether the hydraulic system has abnormal sound, the photoelectric eye, Whether the operation button is an emergency stop switch, the safety protection device is sensitive and reliable; after everything is normal, please select the operation switch according to the required operation method.