Video About KINGREAL 600*600 mm Aluminum Ceiling Tile Production Line

Video About KINGREAL 600*600 mm Aluminum Ceiling Tile Production Line KINGREAL Successful Local Installation Cases

KINGREAL Successful Local Installation Cases

Main Features

Main Features

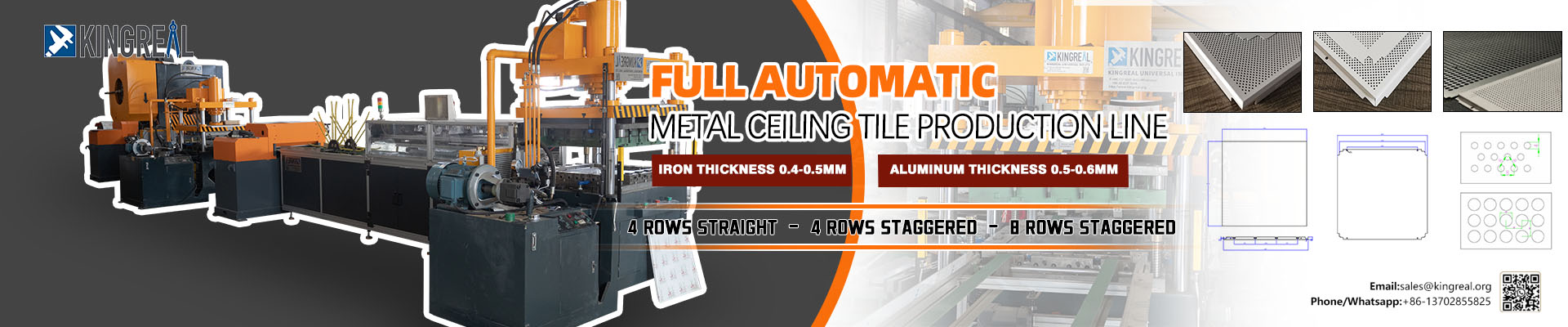

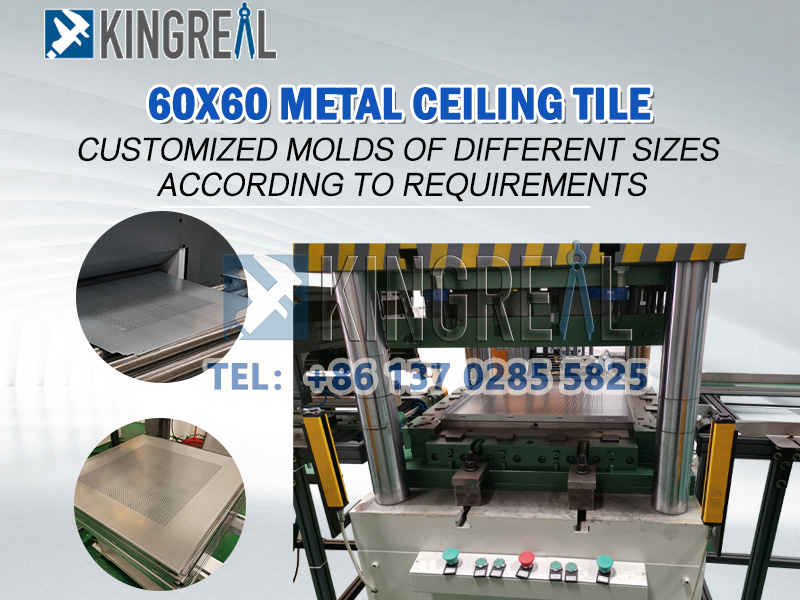

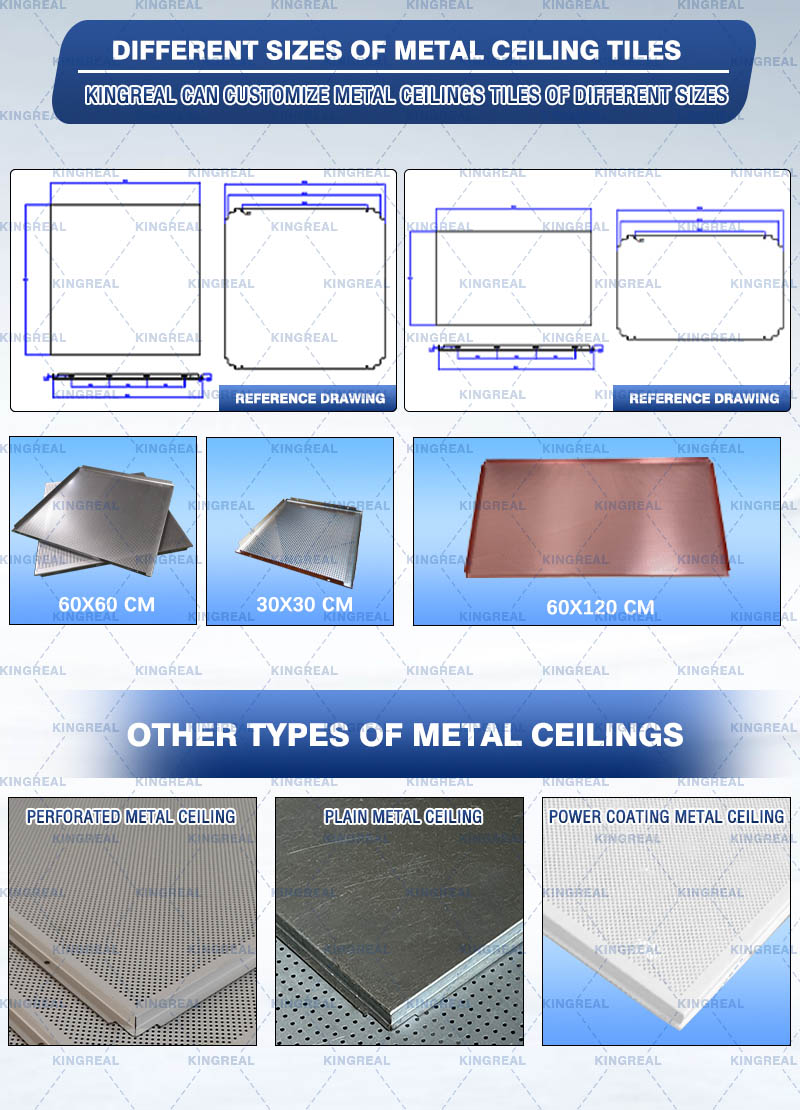

KINGREAL 600x600mm Aluminum Full-Automatic Metal Ceiling Tiles Production Line is one of our most featured products, it can produce both plain and perforated metal ceiling tiles according to customers‘ needs. This ceiling tile production line can produce tiles in sizes such as 30x30 cm, 60x60 cm, and 60x120 cm, as well as various types like clip-in, lay-in, and tegular, by changing the molds. The full- automatic metal ceiling tiles production line is mechanically controlled and sensitive, without manual control of accuracy. It has the characteristics of smooth operation, fast output speed, avoiding injury.

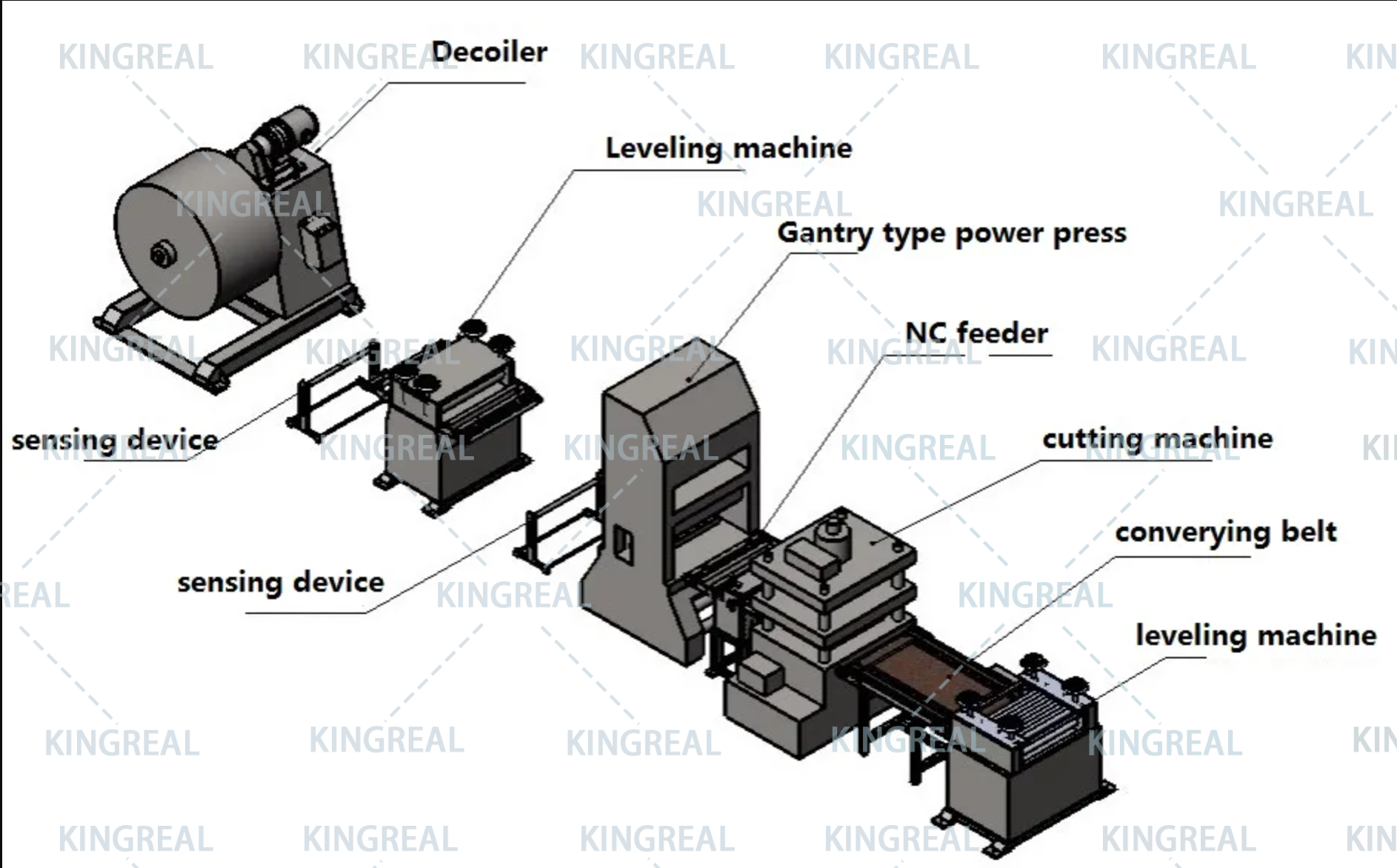

The front part of the 600x600mm metal ceiling tiles production line is composed of a hydraulic decoiler and straightener, both of which are fully automatic type for decoiling and straightening metal coil. The decoiler adopts hydraulic expansion and the straightener is a high precision type with 21 rollers.

Perforation press can perforate metal sheets as per design from clients. By changing stings and molds, this press can provide different perforation patterns. Servo Feeder with quality motor to feed metal sheets for next step production. A notching press can cut corners of metal sheets precisely. This combination is compatible with other sizes such as 300x300mm, 300x600mm ceiling tiles as well.

The final bending forming press is also hydraulically powered, with different molds it can bend and form multiple types of metal ceiling tiles such as Clip-in, Lay-in and Tegular types. Raw tiles are fed by an automatic mechanical arm, which can avoid unnecessary work injuries. This press can be operated as fully automatic or manual. The final products will be transformed into a stacking system for collecting.

The Metal Ceiling Tiles Production Line can use both aluminum and Gi steel coils as raw material. It provides high quality products with different holes of diameters. Clients can customize this production line for specific products like 300x300mm, 600x1200mm tiles.

This production line is featured with our most advanced technology, and it was successfully installed in many countries. We have successfully provided local installation services to customers in Russia, Saudi Arabia, Turkey, Brazil and other places

Composition Of Complete Production Line

Composition Of Complete Production Line

| Machine | Features | Amount |

| Decoiler | Hydraulic expansion | 1 Unit |

| Pre-straightener | High-precision 19 Rollers | 1 Unit |

| 125 Tons High-Speed Perforation Press | 125Tons, 100-150 SPM, 2-5PCS tiles/min | 1 Unit |

| NC Servo feeding machine | Yaskawa Servo motor, 3.0KW High accuracy | 1 Unit |

| Hydraulic notching & shearing press | 60tons Hydraulic press, High accuracy | 1 Unit |

| Transmission conveyor | Automatic | 2 Units |

| Precision straightener | High-precision 21 Rollers | 1 Unit |

| Automatic tiles flipping machine | For flipping 600*600 tiles 180 degrees | 1 Unit |

| Automatic feeding mechanical arm | For feeding 600*600 tiles to next step production | 1 Unit |

| Hydraulic bending forming press | For bending forming 600*600 tiles | 1 Unit |

| Electric control system | Reliable parts | 1 Unit |

Working Process

Working Process

Other Components are Available for Option

Other Components are Available for Option Different Types of Metal Ceiling Tile Solutions

Different Types of Metal Ceiling Tile Solutions

KINGREAL Technical Team

KINGREAL Technical TeamAs a professional manufacturer of metal ceiling tile making machines in China, KINGREAL has been in design - production - installation - after-sales for more than 20 years. KINGREAL is able to customize production solutions according to customer‘s drawings and specific parameter requirements.

After you order, our technical team will test the machine in an effort to ensure every mechanical and electrical part is in perfect condition.

KINGREAL in Diverse Exhibitions

KINGREAL in Diverse Exhibitions

Customer Visit

Customer VisitKINGREAL warmly welcomes customers from all over the world to visit our factory in China. Please do not hesitate to contact us immediately if you need any assistance.

Iranian customer in Kingreal factory