Video Display

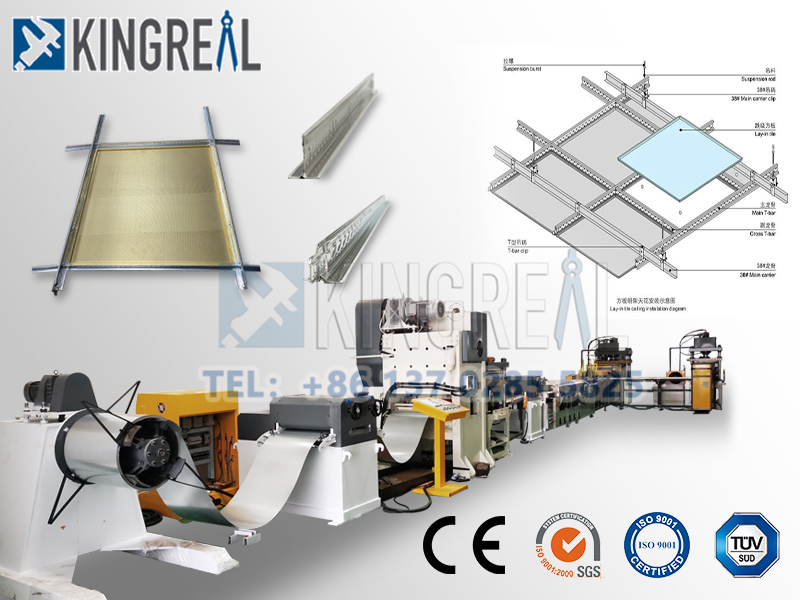

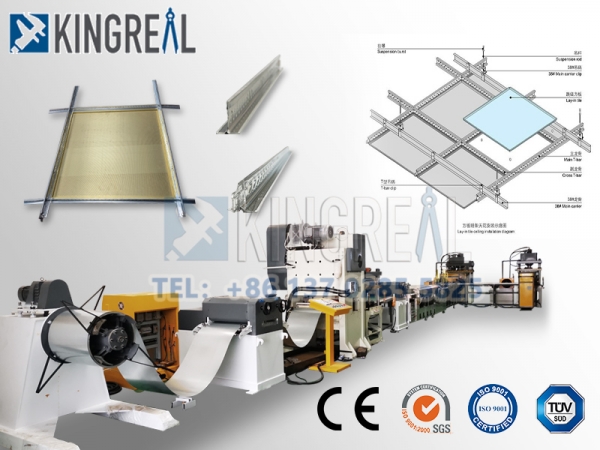

Video Display  Suspended Ceiling Production Line MATCHING Ceiling T Bar Machine Solution

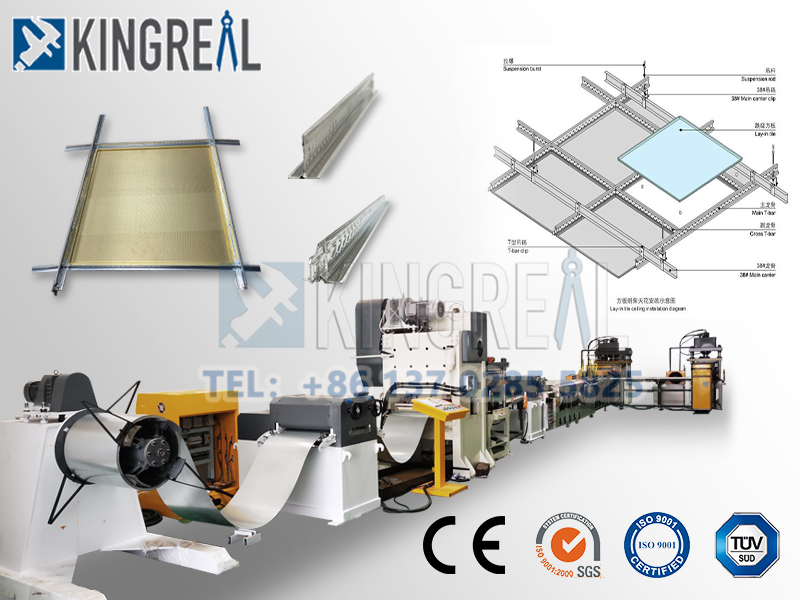

Suspended Ceiling Production Line MATCHING Ceiling T Bar Machine Solution Over 20 years of experience accumulation, KINGREAL has successfully customized suspended ceiling - tee grid solutions for customers from different countries around the world. We can provide a complete solution for your t bar ceiling grid and suspended ceiling production. Such as:

①Main Tee + Cross Tee + Lay-in Tiles

②Main Tee + Cross Tee

③Main Tee + Cross Tee + Wall Angle

Combining to use KINGREAL Suspended Ceiling Production Line and Ceiling T Bar Roll Forming Machine can not only ensure the quality of whole suspended ceiling system, but also make your production smoother and easier.

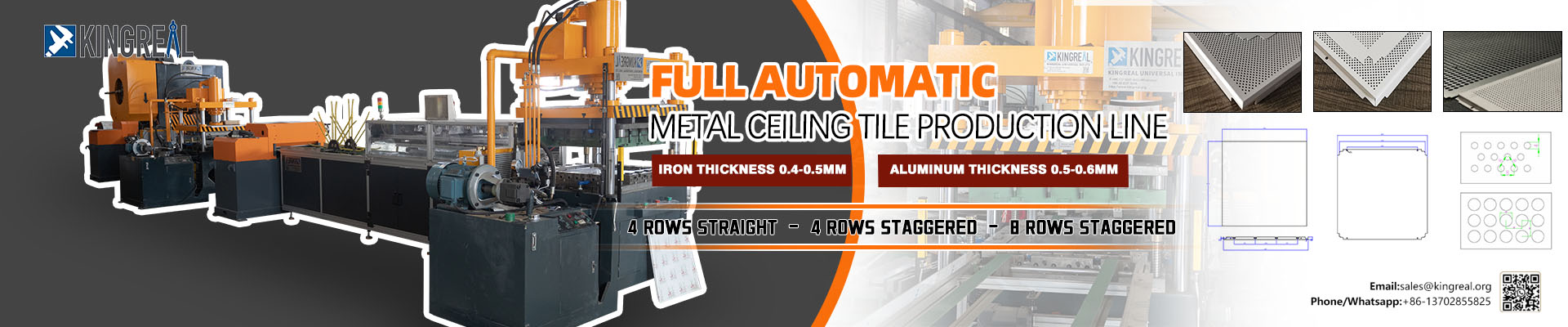

Description of Suspended Ceiling Tiles Production Line

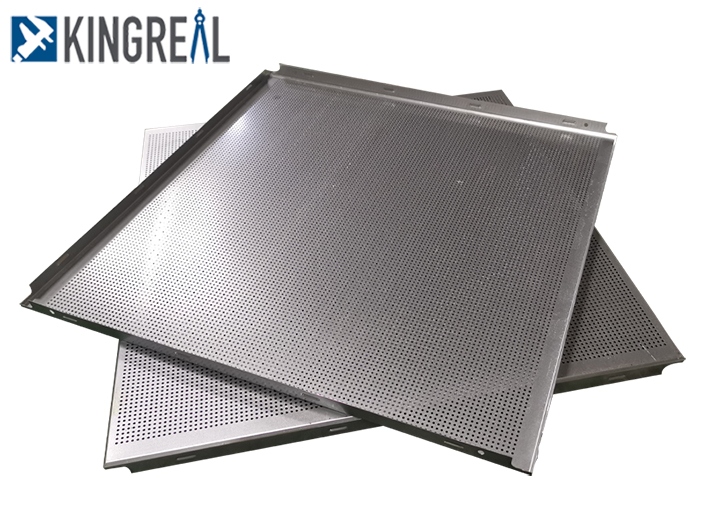

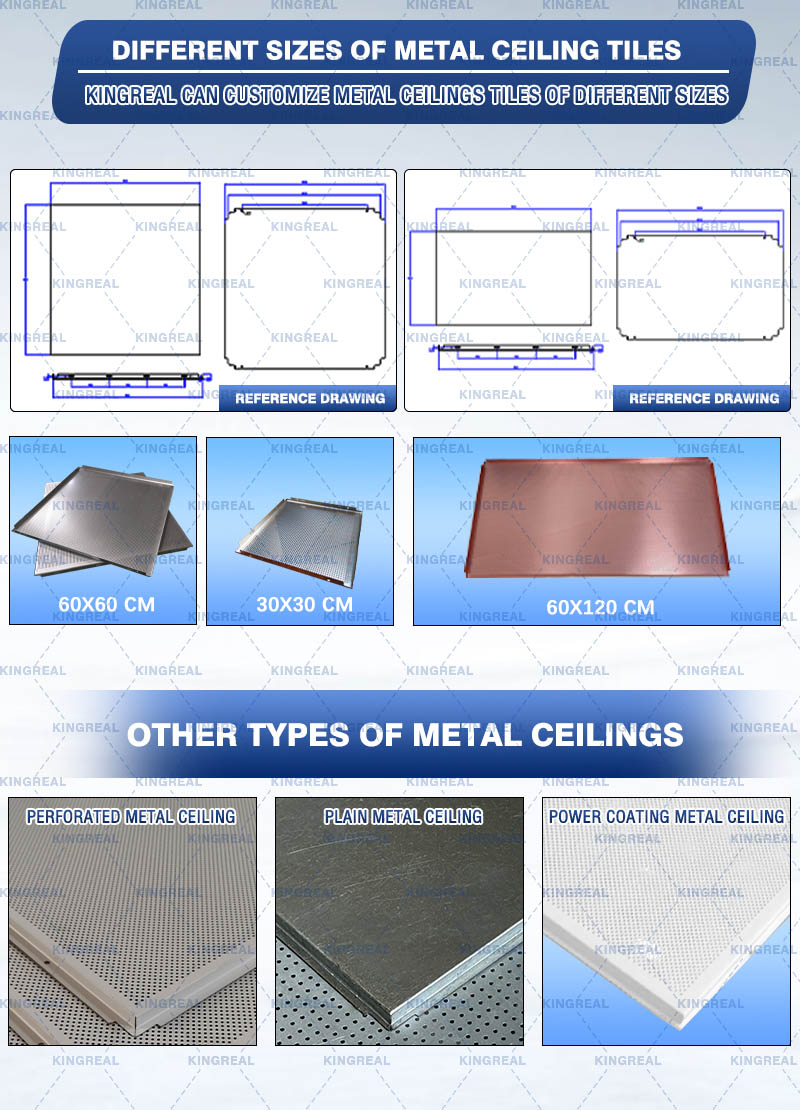

Description of Suspended Ceiling Tiles Production Line As a professional metal suspended ceiling processing machines manufacturer, KINGREAL Full Automatic Metal Ceiling Tile Production Line can used for producing different size lay-in ceiling tiles, including 600*600mm, 300*300mm, 600*1200mm etc. The production of different types of ceilings can also be achieved by changing the mold, such as clip in, tegular and so on. It‘s compatible with multiple materials, including Gi, steel, aluminum.

Automatic metal ceiling production line not only improves production efficiency, but also ensures fast and stable output. It also reduces the risk of worker accidents caused by fatigue, operational error or negligence.

Automatic metal ceiling production line not only improves production efficiency, but also ensures fast and stable output. It also reduces the risk of worker accidents caused by fatigue, operational error or negligence.

KINGREAL also can provide Ceiling T Bar Roll Forming Machines, matching with drop ceiling tiles making machines. The production of drop ceiling tiles and their accessories can be smoother.

Advantages of Lay-in Suspended Ceiling Tiles

Advantages of Lay-in Suspended Ceiling Tiles | Beautiful Appearance Lay-in drop ceiling panels are with a smooth surface, distinct edges and lines. The whole ceiling is regular, graceful and open. White ridges make the ceiling surface uniform and integral. |

|

|

Excellent Performance Lay-in drop ceiling tiles have a good performance: non-combustible, anti-corrosion, damp-proof, and easy to dismantle. As every plate can be installed and dismantled individually, it is very convenient to install, maintain, and clean. |

| Widely Application Lay-in drop ceiling panels are widely used in office buildings, offices, corridors,airports, railway stations, factories, hospitals, clubs,banks,shopping malls, exhibition halls and so on. |

|

Detail Information of Lay in Ceiling Panels Production Line

Detail Information of Lay in Ceiling Panels Production Line  Leveler

Leveler| The leveler adopts 19 rollers straightening devices with 9 top rollers and 10 bottom rollers, which can realize precise leveling. The roller of the leveler is hard chrome plated to ensure the surface smoothness, strength and endurable to avoid the scratch of the tiles‘ surface. |  |

Specification of Leveler

| Width of material | <700 mm |

| Thickness of material | 0.3 - 2.2 mm |

| Feeding speed | 25m / min |

| Overall rollers | 19 |

| Upper rollers | 9 |

| Lower rollers | 10 |

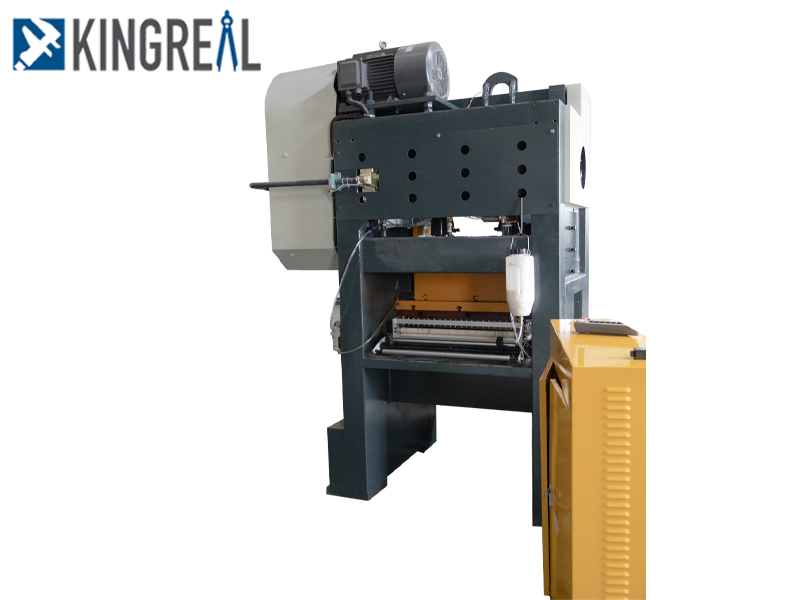

Notching And Shearing Press Machine

Notching And Shearing Press Machine| The Notching And Shearing Press Machine adopts four column oil press structure and is equipped with a sharp cutting tool, so the accuracy of the shearing can be ensured. It can be used to create notches, cuts, and other shapes in the metal material. |  |

Specification of Notching And Shearing Press Machine

| Cylinder pressure force | 60 tons |

| Cylinder stroke | 200 mm |

| Distance between movable crossbeam and worktable | 200 mm (minimum) 400 mm (maximum) |

| Ground clearance of worktable | 850 mm |

| Machine size (W, L, H) | 2100 mm x 1100 mm x 2000 mm |

| Power consumption | 5.5 KW |

| Weight | ~ 4.3 tons |

Perforation Punching Press

Perforation Punching Press| KINGREAL high speed Perforation Punching Press is used for punching holes or shapes into metal sheets that will be used for ceiling applications. can reach 200SPM perforation speed, which can punch Lay-in Ceiling and Clip-in Ceiling at the same time. The perforation press uses a pneumatic brake system to replace the old gear drive system, it is the typical technology for ensuring the accurate perforation and higher speed production. |  |

Specification of Perforation Punch Press Machine

| Output pressure force | 125 tons |

| Punching stroke | 20 mm |

| Aperture of holes | Φ 2.5 |

| Adjustable thickness | 10 mm |

| Punching pierce | 100 - 150 times / min |

| Adjust range of enclosed height | 50 mm |

| Size of wafer stage | 1000 mm x 680 mm |

| Default color | Grey and Orange (Customizable) |

About Ceiling T Bar

About Ceiling T Bar | Advantages Tee grid is characterized by moisture-proof, anti-corrosion, non-fading, easy to install, saving installation time, often used for the installation of lay-in drop ceiling panels. |

|

|

Application Tee grid compartmentalizes the lay-in drop ceiling tiles for clean lines and a three-dimensional look. KINGREAL Ceiling T Bar Roll Forming Machine is designed to produce the t bar grid to be used in lay-in ceiling. |

Specification of Ceiling T Bar Roll Forming Machine

| Material Type | Gi Strip and PPGI |

| Material Thickness | 0.25-0.35mm Gi Steel, 0.18-0.23mm PPGI |

| Production Speed | 0-33m/min Adjustable for Main-T and Cross-T machines |

| Power Supply | AC380V, 50HZ, 3-Phases or to be customized as per request |

Diverse Metal Ceiling Tiles Can be Produced

Diverse Metal Ceiling Tiles Can be Produced

KINGREAL Technical Team

KINGREAL Technical Team KINGREAL has a professional technical team with more than 25 years of relevant experience from the drawing design to the manufacturing of Suspended Ceiling Making Machine and Ceiling T Grid Roll Forming Machine, from design - production - installation - after-sales, our team has an excellent standard.

Services are always highly considered by us, in addition to establishing a complete remote service system, localized after-sales service is also what we have been insisting on doing. The global localization service point is under construction.

Kingreal Factory

Kingreal Factory

To integrate R&D, KINGREAL has established our own factory, located in Foshan, Guangdong. In addition to maintaining close contact online, many of our customers also choose to visit our factory to observe the production of machines and communicate with us face to face. We are looking forward to reaching long-term and stable relationships with customers around the world with our professional capability and consistent level of service!

KINGREAL in Diverse Exhibitions

KINGREAL in Diverse Exhibitions

Kingreal Factory

Kingreal FactoryTo integrate R&D, KINGREAL has established our own factory, located in Foshan, Guangdong. In addition to maintaining close contact online, many of our customers also choose to visit our factory to observe the production of machines and communicate with us face to face. We are looking forward to reaching long-term and stable relationships with customers around the world with our professional capability and consistent level of service!

KINGREAL in Diverse Exhibitions

KINGREAL in Diverse Exhibitions