Video About Metal Ceiling T Bar Making Machine

Video About Metal Ceiling T Bar Making Machine

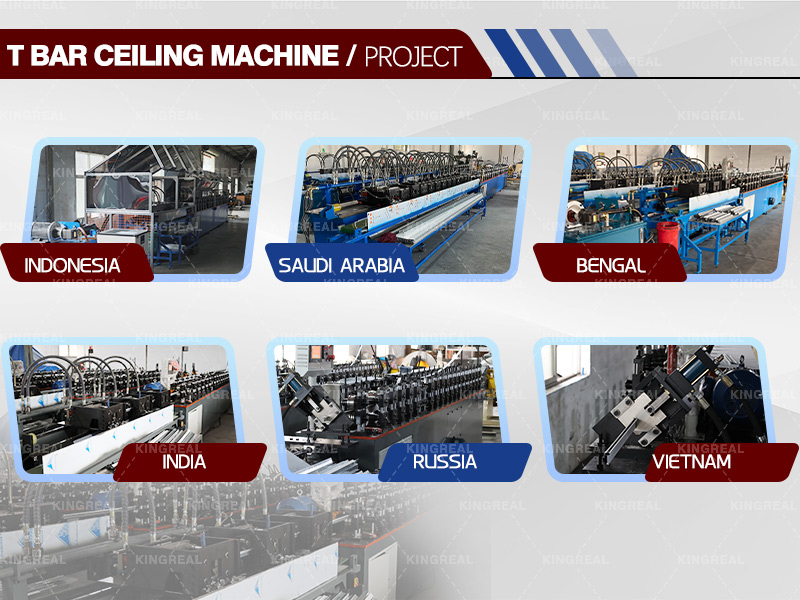

Related Project

Related Project

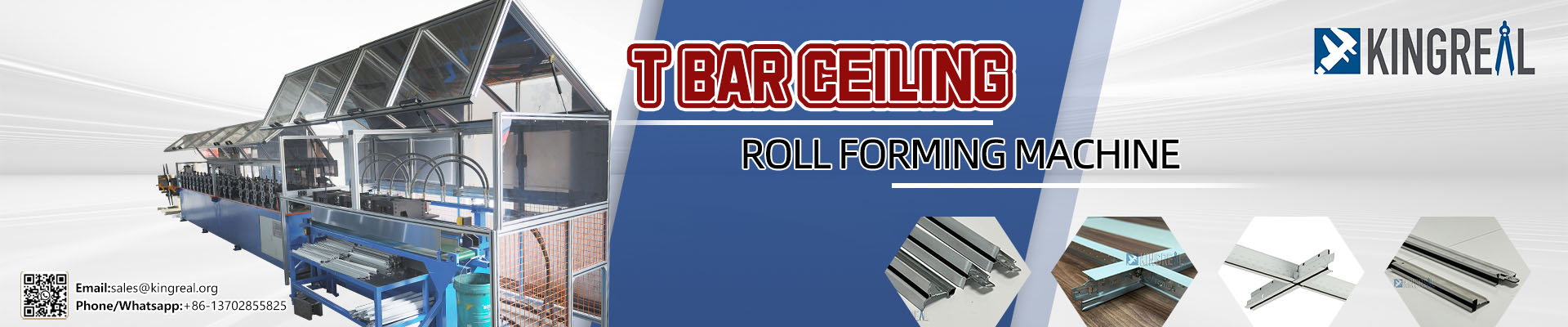

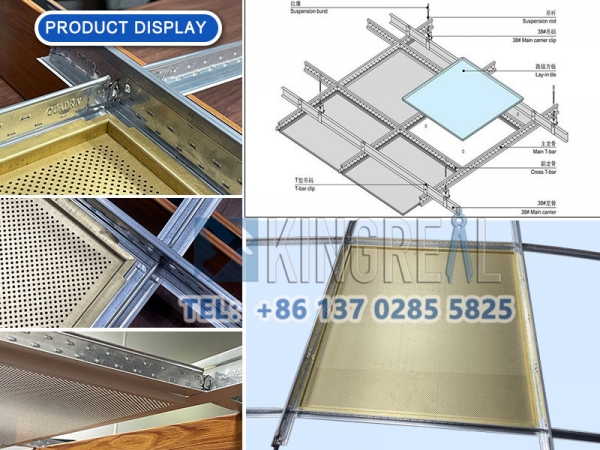

Description of Steel T Bar Roll Forming Machine

Description of Steel T Bar Roll Forming MachineKINGREAL Steel T Bar Roll Forming Machine can forming ceiling t bar with different sizes and different lengths automatically according to customer’s requirement.

As a professional drop ceiling making machine supplier, KINGREAL also can provide a complete solution for your tee grid and suspended ceiling production.

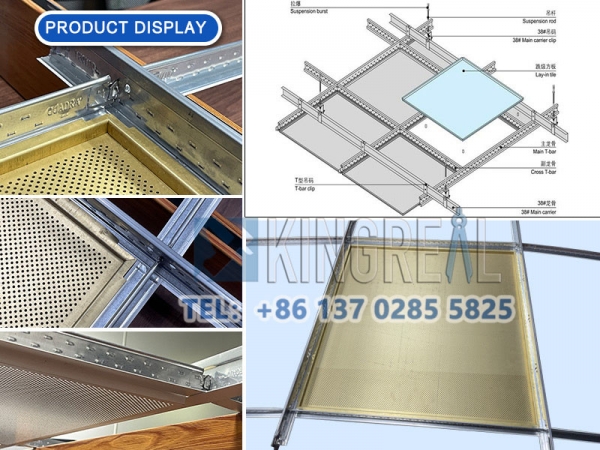

Different Type of Ceiling T Bar Description

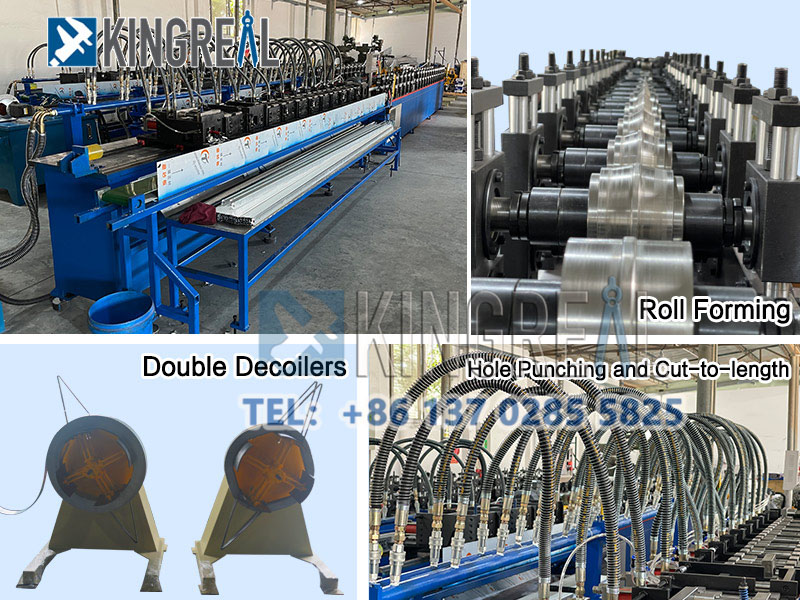

Different Type of Ceiling T Bar Description| Main t bar grid making machine: KINGREAL main t bar grid production line is composed by decoilers, main roll forming machine, Automatic hydraulic cutting off station, hydraulic cooling station and electric control system, etc. - Main Tee bar size:H38*24mm, H32*24mm - Length: 3600mm - Thickness:0.20-0.40mm |

Cross ceiling t bar making machine: KINGREAL cross ceiling t bar production line is composed by decoilers, main roll forming machine, Automatic hydraulic cutting off station, hydraulic cooling station and electric control system, etc. - Cross Tee:H26*24mm, H24*23mm - Length: 1200mm, 600mm - Thickness:0.20-0.40mm |

|

|

|

Features of Steel T Bar Roll Forming Machine

Features of Steel T Bar Roll Forming Machine| 1.Highly precise ①Full automatic with high speed: 30m/min; ②The total length tolerance is ±0.2mm. Tolerance of hole spacing ±0.1mm. |

|

|

2.High quality imported originals All components of the t bar ceiling grid roll forming machine have undergone necessary surface treatment according to the actual working conditions and environment, such as electroplating, hardening, etc., to ensure that the parts have sufficient rigidity and durability. We use high-quality imported electrical appliances, such as Japanese Yaskawa NC servo feeder, PLC from FATEK, MCGS touch screens, which can ensure stable and continuous work of our machines. |

Specification

Specification| Raw materials | Galvanized Steel, Pre-painted Galvanized Steel |

| Material thickness: Galvanized Steel | 0.25-0.35mm; Pre-painted Galvanized Steel: 0.3-0.4mm |

| Finished T bar size | As per customer’s requirement |

| Maximum forming speed | 20-30 m / min |

Complete Solution

Complete SolutionAs one of the most professional false metal ceiling equipment manufacturer in China, KINGREAL can provide a complete provide a complete solution for your t bar ceiling grid and suspended ceiling production. Combination KINGREAL t bar roll forming machine and metal suspended ceiling making machine can make your ceiling production convenient and worry-free.

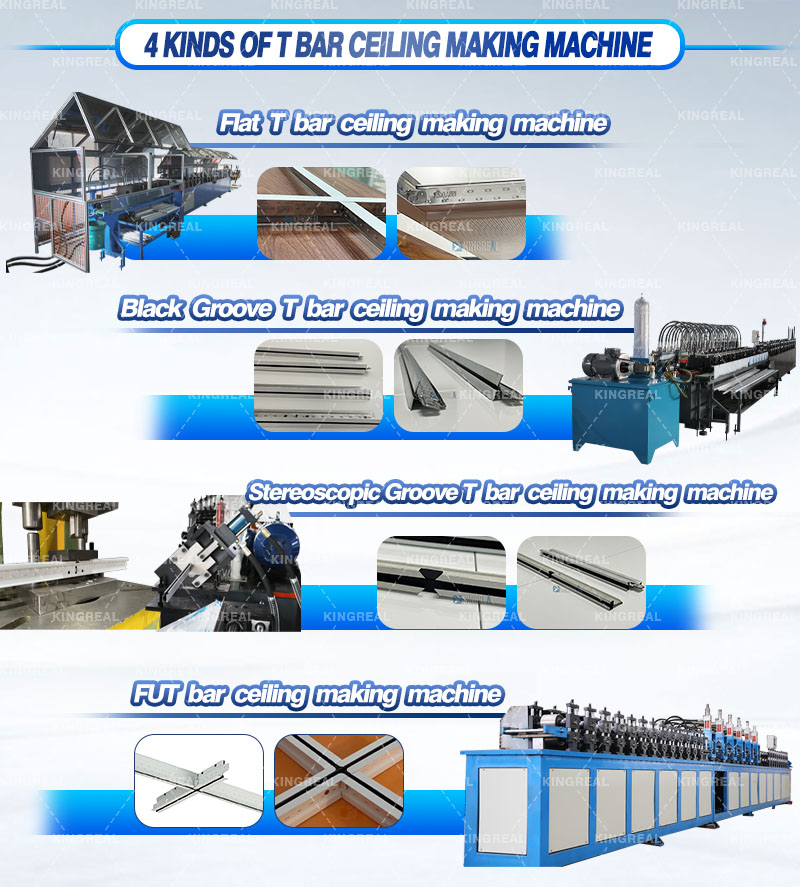

Different Types of Metal Ceiling T Bar Making Machine

Different Types of Metal Ceiling T Bar Making Machine

Quality Insurance

Quality InsuranceKINGREAL has passed ISO9000 certification and has the ability of ISO9000 quality system management.

After you ordered, our technical team will test the machine in an effort to insure every mechanical and electrical parts are in perfect condition.

Customer Visit

Customer VisitIt is such a delight to have friends coming from afar. KINGREAL is warmly welcome customers to visit our factory and communicate with us!