Video About Tee Grid Roll Forming Machine

Video About Tee Grid Roll Forming Machine Description of Tee Grid Roll Forming Machine

Description of Tee Grid Roll Forming Machine

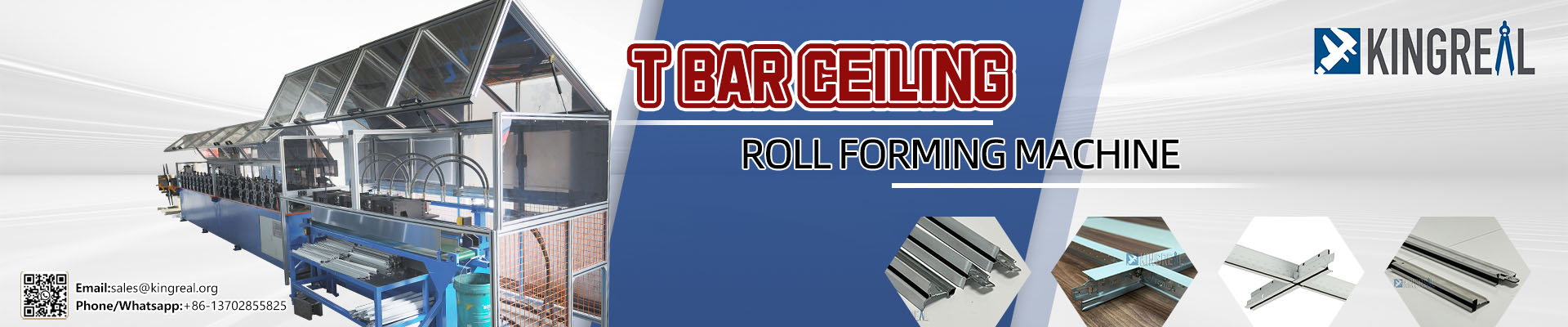

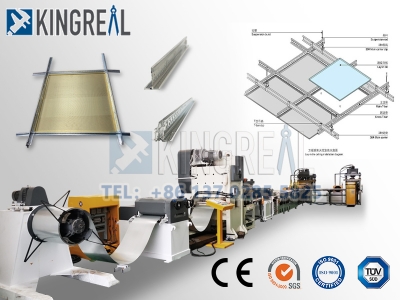

KINGREAL T Bar Ceiling Grid Making Machine series are 3 machines that can produce main T-bars, cross T-bars and angle profiles. This combination features with fully automatic type, multi station punching and fast production.

Main components: Decoilers, Punching press, Servo feeder, Main roll forming machine, Automatic shearing station, Output table and electrical control system.

The t bar grid production lines can produce various sizes of products such as 38x24mm, 32x24mm, 24x24mm, 22x22mm etc.

The main roll forming machine is featured with precision forming, shearing station with hydraulic shearing and durable cutting blades. All production lines are PLC controlled and operating system with touch screen.

KINGREAL equipped lubrication system for main roll forming machine to reduce waste heat during production.

Thick panel to protect the forming machine itself, archway structure to build roller stations. Cr12MoV mold steel to make rollers for cold roll forming.

Hydraulic follow a shearing station will cut product to length precisely, cutting blade is durable under long-time working conditions.

Clients can buy multiple machines for different sizes of T-grid production, which not only saves time but also provides high efficiency.

Specification

Specification| Raw materials | Galvanized Steel, Pre-painted Galvanized Steel |

| Material thickness | Galvanized Steel: 0.25-0.35mm; Pre-painted Galvanized Steel: 0.3-0.4mm |

| Finished T bar size | As per customer’s requirement |

| Maximum forming speed | 20-30 m / min |

Main Processes of Drop Ceiling T Bar Roll Forming Machine

Main Processes of Drop Ceiling T Bar Roll Forming Machine Hydraulic Decoiler -- Main Roll Forming -- Hydraulic Punching and Cutting -- Output

.png)

Complete Solution

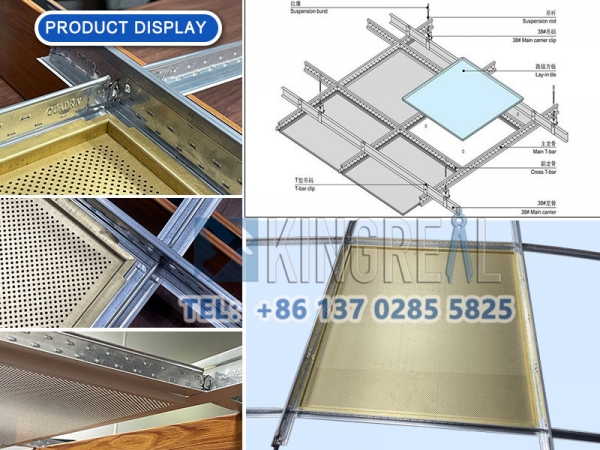

Complete Solution As one of the most professional false metal ceiling equipment manufacturers in China, KINGREAL can provide a complete solution for your t bar ceiling grid and suspended ceiling production. A combination of a KINGREAL steel tee bar roll forming machine and a metal suspended ceiling making machine can make your ceiling production convenient and worry-free.

Common T Bar Grid Sizes

Common T Bar Grid SizesA) 32H Model:

I) Main tee: 32mm x 24mm x 3.0m, or 3.05m, 3.60m, 3.66m

Ii) Cross tee: 26mm x 24mm x 1.2m, or 1.22m

Iii) Cross tee: 26mm x 24mm x 0.6m, or 0.61m

Iv) Wall angle: 20mm x 20mm x 3.05m, or 3.60m 22mm x 22mm x 3.05m, or 3.60m 24 mm x 24mm x 3.05m, or 3.60m

V) Thickness: From 0.23mm, 0.25mm, 0.28mm, to 0.30mm and 0.40mm

Ii) Cross tee: 26mm x 24mm x 1.2m, or 1.22m

Iii) Cross tee: 26mm x 24mm x 0.6m, or 0.61m

Iv) Wall angle: 20mm x 20mm x 3.05m, or 3.60m 22mm x 22mm x 3.05m, or 3.60m 24 mm x 24mm x 3.05m, or 3.60m

V) Thickness: From 0.23mm, 0.25mm, 0.28mm, to 0.30mm and 0.40mm

B) 38H Model:

I) Main tee: 38mm x 24mm x 3.0m, or 3.05m, 3.60m, 3.66m Ii) Cross tee: 26mm x 24mm x 1.2m, or 1.22m Iii) Cross tee: 26mm x 24mm x 0.6m, or 0.61m Iv) Wall angle: 20mm x 20mm x 3.05m, or 3.60m 22mm x 22mm x 3.05m, or 3.60m 24 mm x 24mm x 3.05m, or 3.60m V) Thickness: From 0.23mm, 0.25mm, 0.28mm, to 0.30mm and 0.40mm

Product Display

Product Display

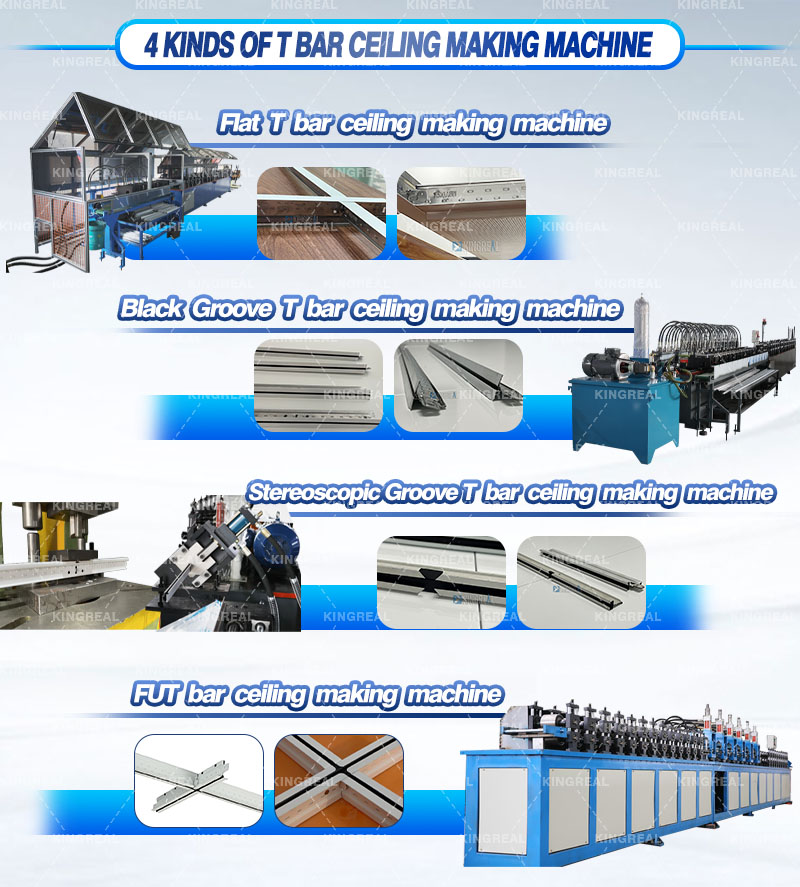

What Ceiling T Bar Making Machine Can KINGREAL Supply?

What Ceiling T Bar Making Machine Can KINGREAL Supply?

KINGREAL Technical Team

KINGREAL Technical TeamKINGREAL has a professional technical team with more than 25 years of relevant experience from the drawing design to the manufacturing of Ceiling T Bar Making Machine, from design - production - installation - after-sales, KINGREAL has an excellent standard.

KINGREAL has established a localized technical support team in Indonesia, Brazil, Saudi Arabia, Canada, India etc.. Localized service points in other countries are also in progress.

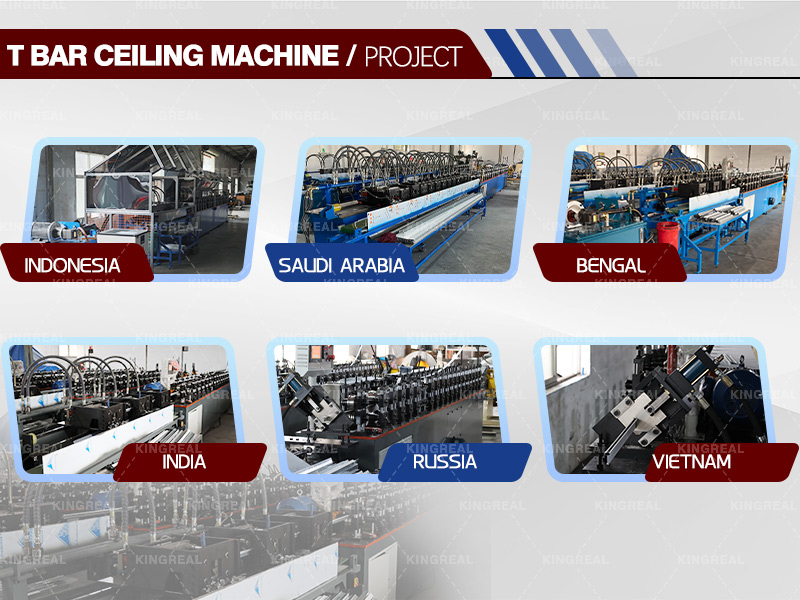

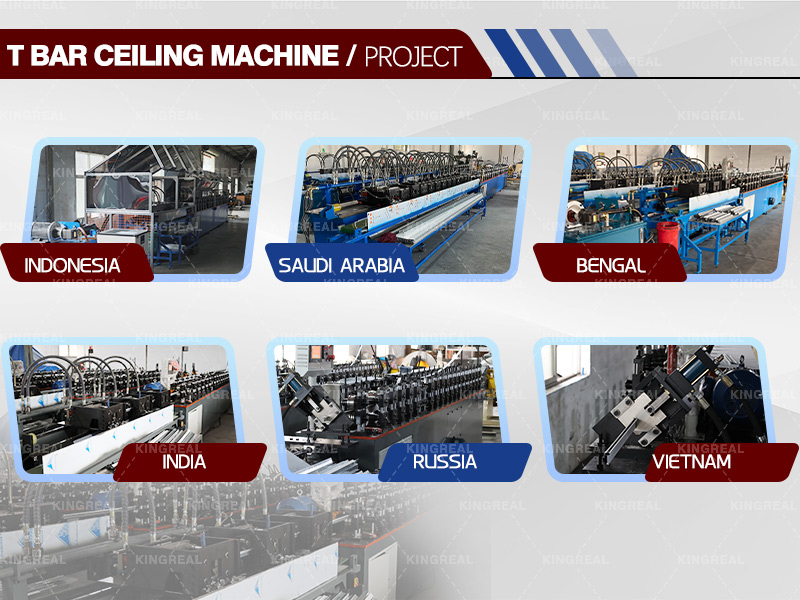

After-Sales Instalation Projects

After-Sales Instalation Projects

Services are always highly considered by us, in addition to establishing a complete remote service system, localized after-sales service is also what KINGREAL has been insisting on doing. The global localization service point is under construction.

KINGREAL has established a localized technical support team in Indonesia, Brazil, Saudi Arabia, Canada, India etc.. Localized service points in other countries are also in progress.

After-Sales Instalation Projects

After-Sales Instalation ProjectsServices are always highly considered by us, in addition to establishing a complete remote service system, localized after-sales service is also what KINGREAL has been insisting on doing. The global localization service point is under construction.