Greek Customer Visit KINGREAL Factory -- Automatic Metal Ceiling Tiles Production Line

Time:2024-09-03

Views:262

Recently, after several days of online communication with KINGREAL‘s technical staff about the machine details, a Greek client, who was highly interested in the fully automatic ceiling panel production line, accepted KINGREAL‘s invitation to visit our factory for an on-site inspection. The main purpose of the visit was to assess the machine‘s operation and ensure the product quality met the Greek client‘s requirements.

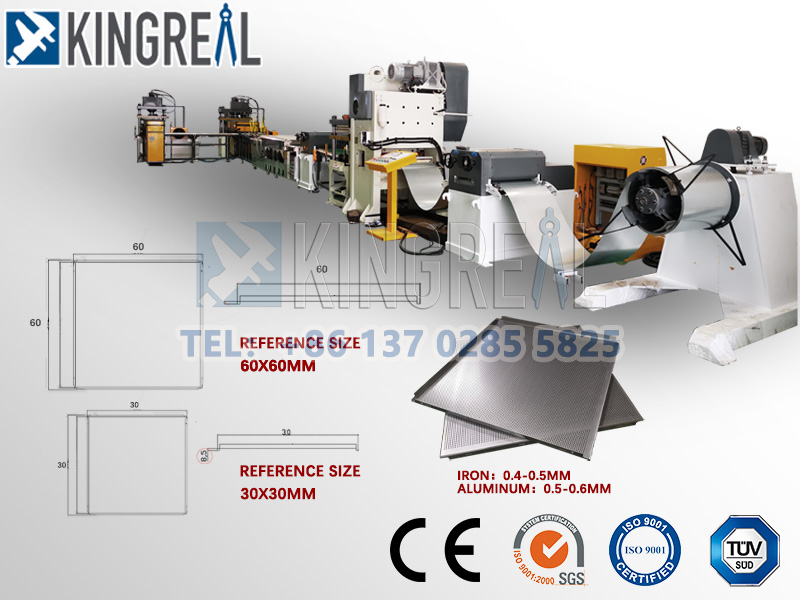

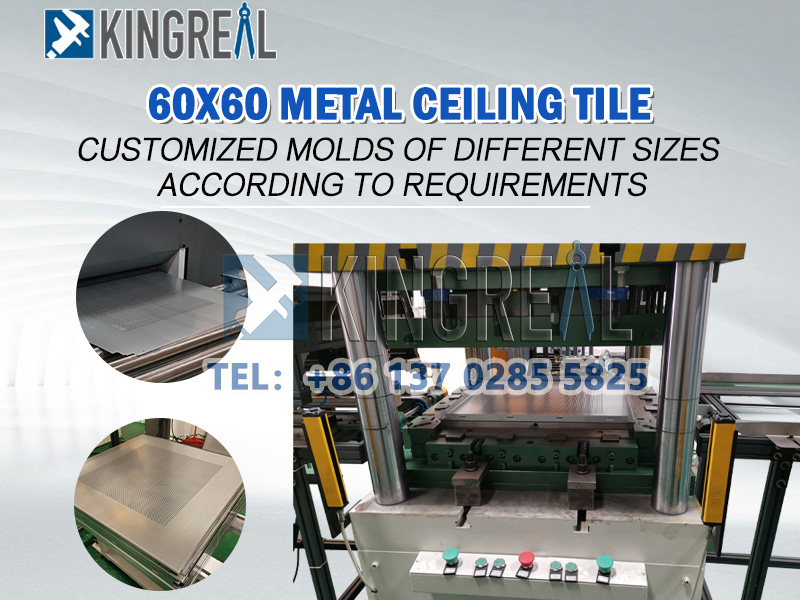

During the factory visit, KINGREAL staff introduced the ceiling tiles production line, which consists of key components such as the decoiler, straightener, punching machine, feeding machine, cutting machine, and bending press machine. The production process involves leveling, punching, and cutting corners of the metal ceiling panels. The client raised several questions, such as whether one production line could produce different types of metal ceiling panels. KINGREAL‘s technicians provided detailed answers, explaining that by changing molds, the automatic ceiling panel production line can flexibly produce various types of panels (clip-in, lay-in, tegular, etc.) and sizes (including 30x30, 60x60, 60x120). The easy mold changeover saves time and reduces costs associated with purchasing additional machinery. The Greek client expressed strong approval of KINGREAL‘s equipment and reached a preliminary cooperation agreement with KINGREAL.

The KINGREAL fully automatic ceiling panel production line features the following key attributes:

| 1. Automatic: The fully automated ceiling tiles production line uses self-developed automatic feeding robots, automatic turning, and stacking systems to achieve complete automation in metal ceiling tile production. It is easy to operate, runs smoothly, has a high output speed, and minimizes workplace injuries. |

|

|

2. Cost Reduction and Safety: Controlled by precise mechanical actions, the fully automatic ceiling tiles production line eliminates the need for manual control, reducing labor costs and safety risks for workers. |

|

3. Waste Reduction:

The hydraulic press cuts the four corners and folds the four edges in one step, reducing waste and saving costs. |

|

KINGREAL‘s fully automatic ceiling panel production line is one of our most distinctive products and one of the most purchased by ceiling manufacturers. With over 20 years of experience in design, production, installation, and after-sales service, KINGREAL offers customized production solutions based on clients‘ blueprints and specific parameters. Customer satisfaction is the greatest support for KINGREAL, and we will continue to strive for excellence in the ceiling panel production line industry. If you need a ceiling tiles production line, please contact us.