How is an open cell ceiling?

Time:2024-08-23

Views:172

When decorating our new home, we often use ceiling grids to handle our ceilings. The advancement of decoration technology has led to a variety of ceiling grid types and styles, with open cell ceilings being quite popular currently. KINGREAL is a professional manufacturer of open cell ceiling roll forming machines. If you have any questions, feel free to consult us! So, what exactly is a open cell ceiling? Let me explain in detail.

1. What is an Open Cell Ceiling?

1. What is an Open Cell Ceiling?

To understand open cell ceilings, we first need to know what they are. An open grid ceiling is a ceiling made of a gridded pattern, typically an open mesh structure. Open grid ceiling tiles are commonly seen in various places such as stylish restaurants, simple and modern exhibition halls, spacious and bright airports, unique bars, large shopping malls, and crowded subway stations. Open grid ceiling tiles give these places distinct features and often create a striking visual impression.

2. Why Choose a Open Cell Ceiling?

(1) Material Savings: It is the most material-efficient method for the same load-bearing conditions, which reduces the amount of support structure materials needed.

(2) Cost-Effective: Savings on materials, labor, and construction time, and requires no cleaning or maintenance.

(3) Easy Installation: Can be installed by one person using bolts on pre-installed supports.

(4) Short Construction Time: No need for on-site processing; installation is very quick.

(5) Durability: Treated with hot-dip galvanizing for corrosion resistance, strong impact, and pressure resistance.

(6) Modern Aesthetics: Attractive appearance, standard design, good ventilation, and light transmission, giving a smooth, modern feel.

(7) Lightweight Structure: Minimal material usage, light structure, and easy to hang.

(8) Prevents Accumulation of Debris: Does not trap rainwater, snow, or dust.

(9) Reduces Wind Resistance: Good ventilation performance means less wind resistance in strong winds, reducing wind load damage.

3. Open Cell Ceiling Size Specifications

(1) Open Grid Ceiling Tiles Standards: 10mm or 15mm thick, with heights available in 40mm, 60mm, and 80mm.

(2) Aluminum Grid Sizes: 50x50mm, 75x75mm, 100x100mm, 125x125mm, 150x150mm, 200x200mm.

(3) Sheet Grid Common Sizes (mm): 10x10, 15x15, 25x25, 30x30, 40x40, 50x50, 60x60.

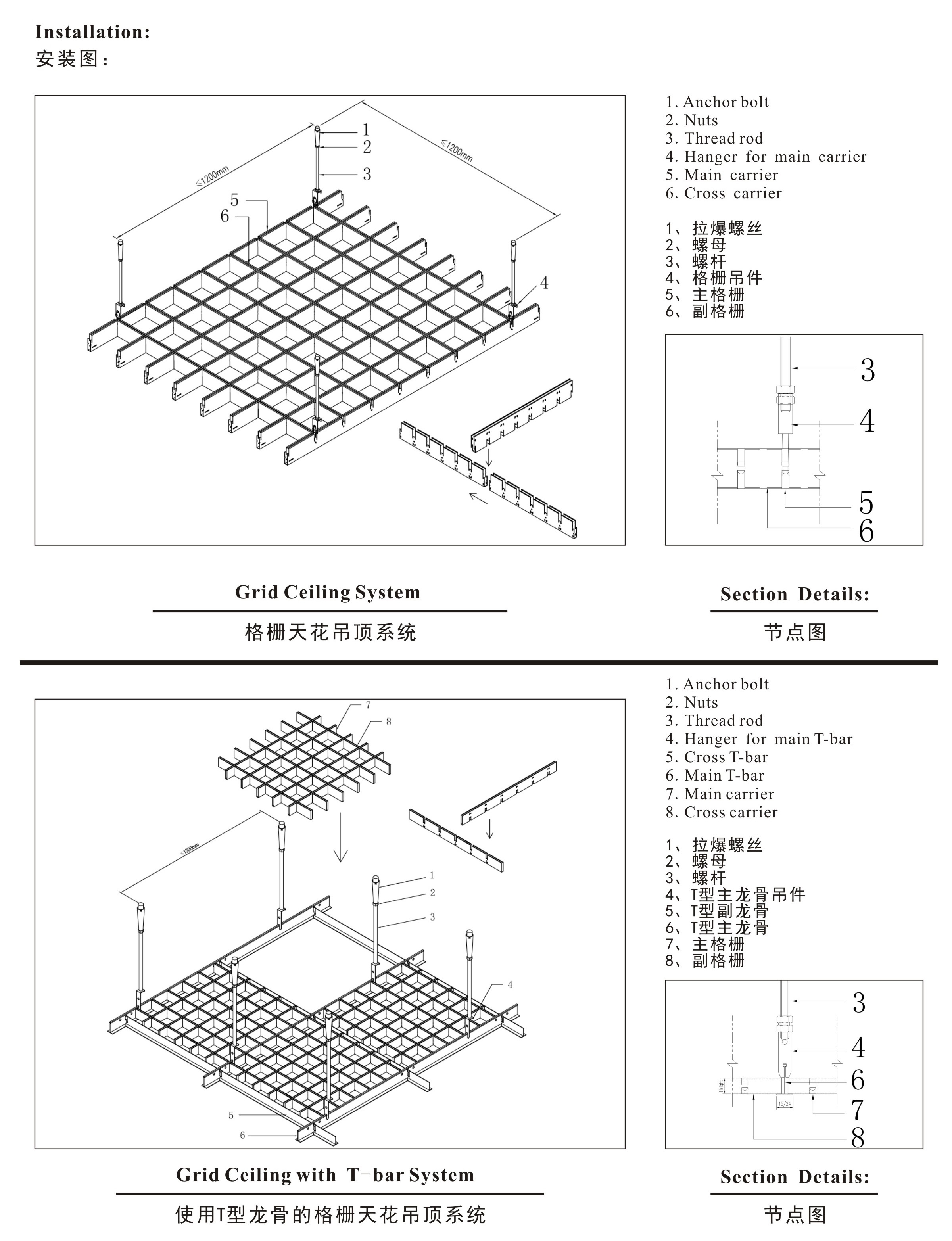

4. How to Install a Open Cell Ceiling?

(1) Marking Lines

Use a level to mark horizontal points on each wall (or column) in the room (for long walls, mark several points in between). Snap a level line (generally 500mm above the floor), measure to the design height of the ceiling, and mark this line along the walls (or columns). This will be the bottom line of the open cell ceiling. Also, mark the position of the main beams on the concrete slab according to the ceiling grid layout. The main beams should extend from the center of the ceiling to the sides, with a maximum spacing of 1000mm, and mark the fixing points for the hanging rods, spaced 900mm to 1000mm apart. If there are beams and pipes with fixing points exceeding design requirements, additional fixing points should be added.

(2) Fixing Hanging Rods

Use expansion bolts to fix the hanging rods, which can be made of 6mm diameter rods. Rods can be cold-drawn steel or round steel, with the latter needing to be straightened mechanically. One end of the rod should be welded to an L30x30x3 angle bracket (the hole diameter of the angle bracket should match the diameter of the rod and expansion bolts), and the other end can have a threaded rod greater than 100mm, or you can purchase pre-made threaded rods and weld them. The finished hanging rods should be rust-proofed, and fixed to the floor slab with expansion bolts, using an impact drill to make holes slightly larger than the bolts‘ diameter.

(3) Installing Light Steel Beams

The light steel beams should be hung on the rods (this step can be skipped if the ceiling is low and proceed directly to the next step). Generally, 38mm light steel beams are used, spaced 900mm to 1000mm apart. The beams should be installed parallel to the length of the room and arched with a height of 1/200 to 1/300 of the room span. Cantilever sections should not exceed 300mm; otherwise, additional rods should be added. The joints of the main beams should be butt joints, with adjacent joints staggered. After the light steel beams are hung, they should be roughly leveled. For ceilings spanning more than 15m, add a large beam every 15m on the main beams, perpendicular to and securely welded to the main beams.

(4) Installing Spring Clips

Connect the spring clips to the light steel beams using rods (if the ceiling is low, you can install the spring clips directly on the rods to skip this step), spaced 900mm to 1000mm apart, then clip the spring clips onto the rods.

(5) Assembling Grid Main and Secondary Beams

Pre-assemble the main and secondary beams of the grid according to the design drawings.

(6) Installing the Open Cell Ceiling

Hang the pre-assembled open cell ceiling using hooks through the main beam holes. Connect and adjust the open cell ceiling until it is level.

5. Precautions

(1) Ceiling Plane Position Accuracy: Due to the large area of each layer, ensure the vertical or parallel alignment of the metal grid with mineral wool boards, the ceiling with walls, and columns. Measure the relevant axes on the wall and columns and use these reference lines for leveling and plastering to ensure that walls are parallel to the axes and adjacent surfaces are perpendicular. Use this as the reference plane for the ceiling position.

(2) Arching Form and Height: The arch height can be about 1/200 of the column span (for 8m column spacing).

(3) Fire Sprinkler Head Position: The plane position of the sprinkler head must not overlap with the grid bars and should be straight in both directions. Create a large bend greater than 900mm at the top of the sprinkler riser for fine adjustments.

(4) Equipment Inspection Openings: Since various pipes in the open cell ceiling have adjustment valves, leave inspection openings in the corresponding positions, though they may not be aligned. Cut holes first, then add corner aluminum around the holes (painted the same color as the grid), with the corner aluminum recessed 2mm from the grid surface. Finally, adjust and fit the grid strips cut from the holes onto the corner aluminum.

(5) Node Treatment between Ceiling and Walls/Columns: Use L20mm x 20mm angle aluminum for connections with square columns to coordinate with the mineral wool board edge beams. For connections with round columns, use 35mm stainless steel pipe rings for closure.

Conclusion

The unique open space of the aluminum open cell ceiling system is beneficial for arranging ventilation facilities and fire sprinklers without affecting the overall visual effect. It is also easy to match with various lighting fixtures and devices, has a strong anti-oxidation feature, can be assembled and disassembled multiple times, and facilitates equipment maintenance. This makes it a popular choice for many large commercial spaces.