What do baffle ceilings do?

Time:2024-09-06

Views:111

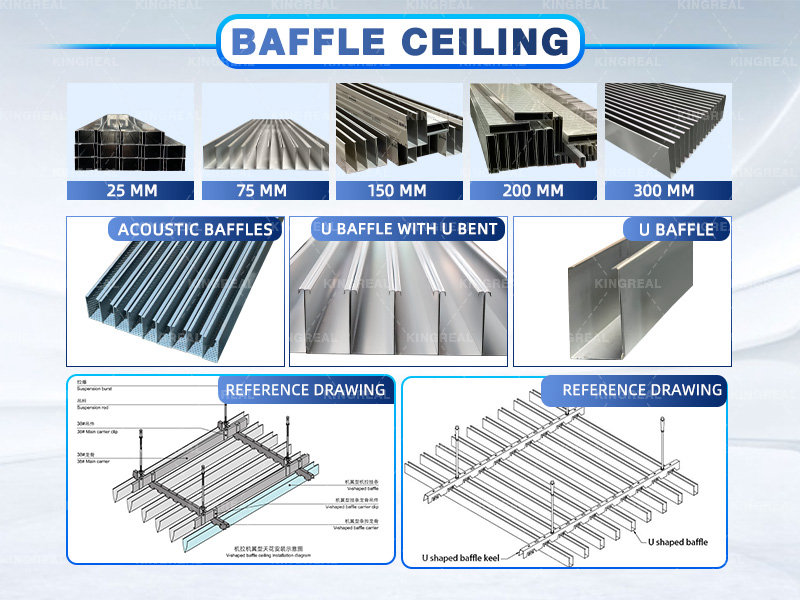

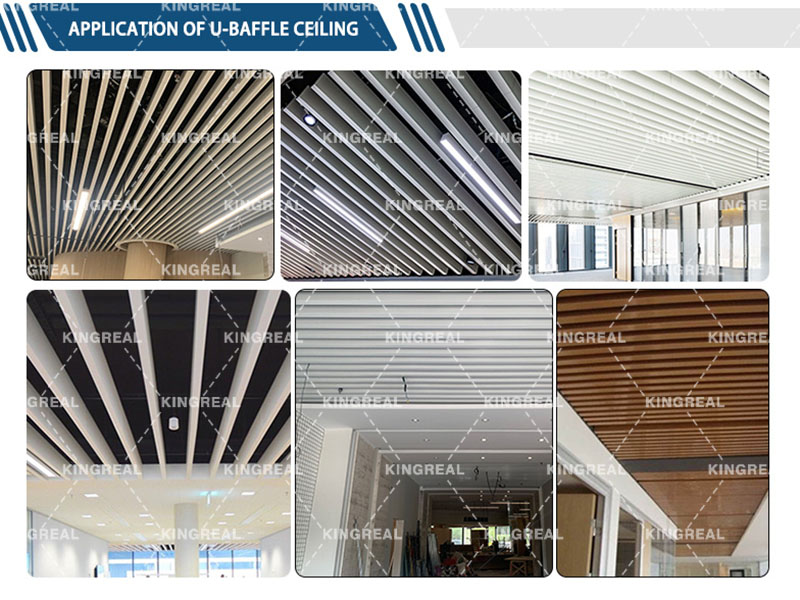

Aluminum baffle ceiling, also known as u shaped baffle ceiling, is a type of ceiling made from aluminum and has become one of the common ceiling styles in recent years. It features an open view, good ventilation, and breathability. The clean and straight lines with clear layering showcase a modern and minimalist style. Its easy installation and disassembly have made it a popular choice in the decorative market.

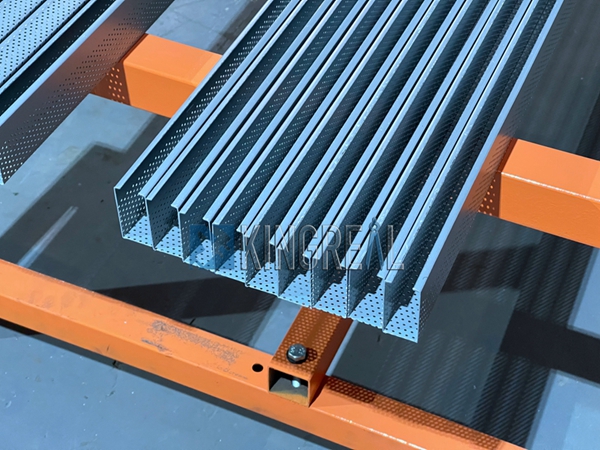

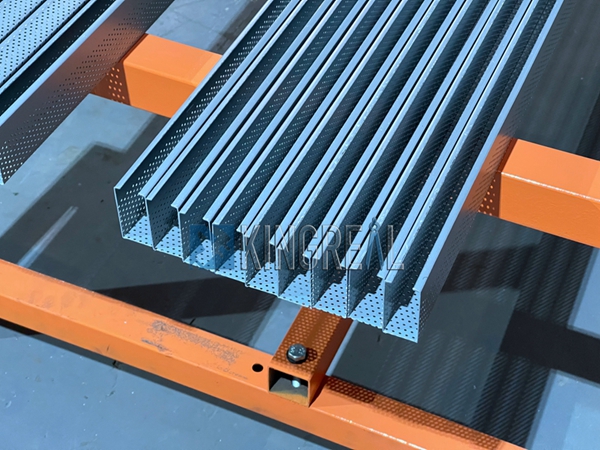

Metal baffle ceilings are produced through processes like flattening, shaping, and cutting metal raw materials using a baffle ceiling roll forming machine. This article will provide a detailed introduction to aluminium baffle ceiling.

Types of Materials

Aluminium baffle ceilings are mainly divided into aluminum plate baffle ceilings and profile aluminum baffle ceilings.

1. Aluminum Plate Baffle Ceilings

Aluminum plate baffle ceilings are formed through continuous rolling or cold bending. The installation structure uses a special keel clip design, similar to conventional strip panels, making installation straightforward and suitable for indoor decoration (the keel can be designed with wind-resistant clips).

2. Profile Aluminum Baffle Ceilings

Profile aluminum baffle ceilings are characterized by aluminum materials extruded into shape. The product has higher hardness and straightness compared to others. The installation structure uses a top main keel with screws and special components connecting to profile hammer plates, providing strong wind resistance and suitability for outdoor decoration (the keel spacing can be adjusted freely). Special aluminum beams can be bent into arcs, offering designers a broader space for creative and unique designs.

Material Characteristics

1. Simple and quick installation does not delay the construction period. It has low maintenance costs and can be easily installed and removed.

2. Versatile use in high-traffic public spaces such as subways, high-speed railway stations, airports, etc. It facilitates air circulation, ventilation, and heat dissipation while evenly distributing light, making spaces feel bright and open.

3. Customizable in terms of specifications, sizes, shapes, and colors. It allows flexible adjustment of the visual height of the upper space.

Surface Treatment

The surface treatments for aluminum baffle ceilings include spraying, baking, rolling coating, and film covering. Spraying and baking have shorter lifespans and are prone to color differences. Rolling coating has a moderate lifespan, while film covering, which includes regular and imported films, can last up to 20 years without color change.

Reasons for Choosing Profile Aluminum Baffle Ceilings for Premium Locations

Profile aluminum baffle ceilings are high-end ceiling decoration products made from aluminum alloy profiles. They are formed through heavy extrusion, offering superior hardness, straightness, and smoothness compared to standard aluminum baffle false ceiling. Such baffle false ceilings have strict thickness requirements, not less than 0.6mm; larger sizes are typically above 0.8mm to ensure processing standards. They are less convenient to install than other aluminum baffle ceilings, resulting in higher costs and are suitable for upscale locations rather than wholesale.

Profile aluminum baffle ceilings use a top main keel, fixed with screws and specialized components to connect to profile hammer plates, offering strong wind resistance and suitability for outdoor decoration (keel spacing can be adjusted as needed). Special profile aluminum baffle false ceilings can be bent into arcs, providing designers with a broader creative space for unique and aesthetically pleasing designs.

Advantages of Profile Aluminum Baffle Ceilings

1. Performance Advantages: Made of aluminum alloy, they are hard, pressure-resistant, and wind-resistant. High-quality aluminum alloys are non-flammable, heat-resistant, and have excellent fireproofing effects. The surface is smooth, delicate, and visually appealing with bright, pure colors.

2. Installation Effectiveness: Installation requires a main keel and suspension rods, with beams fixed by screws. Disassembly involves simply unscrewing, and since each profile beam is independent, there is no large-scale disassembly. Repeated disassembly does not deform the beams.

3. Outstanding Decorative Effect: Profile aluminum baffle false ceilings have high hardness and are better for straight lines than U-shaped aluminum beams, making them easy to cut. For instance, they can be cut at a 45-degree angle without deformation, a feature not achievable with other materials. This makes them ideal for creating various shapes.

Profile aluminum baffle ceilings offer different spatial options and can be combined with decorative panels to enhance the unique effect of the site. They are popular in the construction and decoration market and are widely used in airports, stations, shopping malls, restaurants, lobbies, supermarkets, corridors, entertainment centers, and other public spaces.