What is a sheet metal perforating machine?

Time:2024-10-09

Views:8

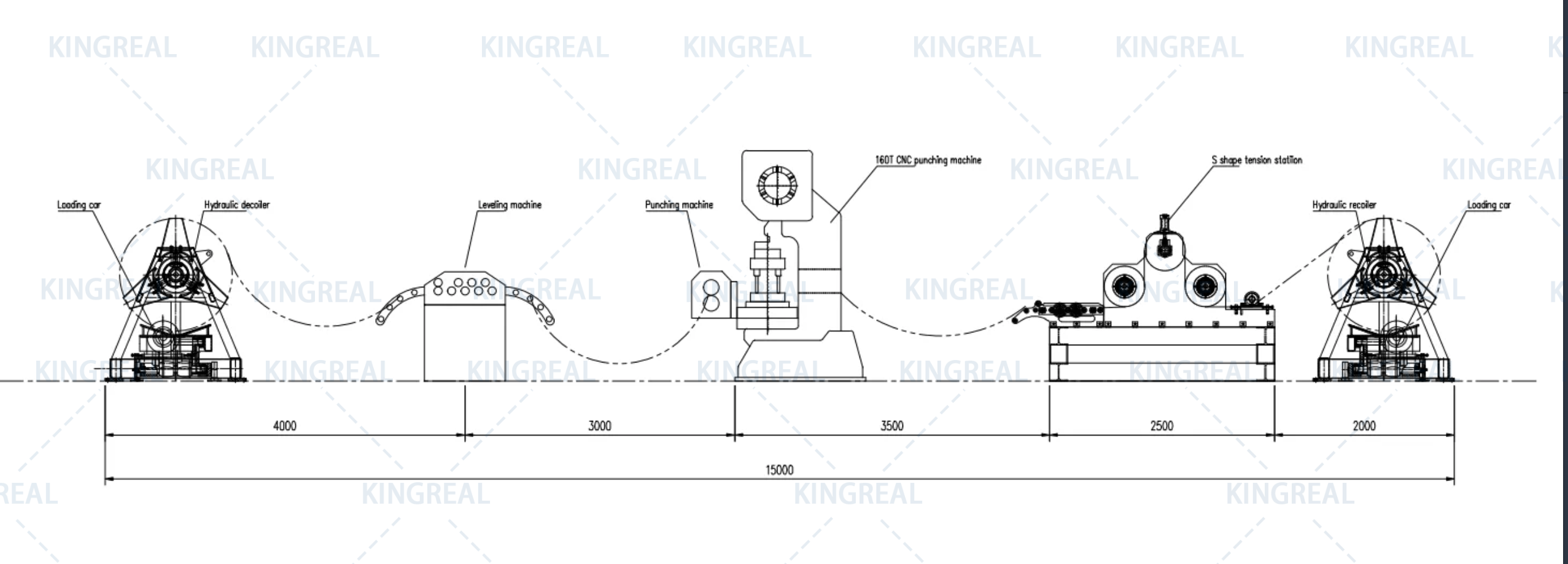

The perforated punching machine is a common metal sheet processing device. Its working principle involves using mechanical force to punch holes or raised shapes in metal sheets with a punch. This article provides a detailed introduction to perforated sheet machine.

Main Components of a Perforated Punching Machine

Machine Body:

Comprises the base, column, mechanical arm, and hydraulic cylinder. The frame supports and stabilizes the entire machine, ensuring strong stability and rigidity. The slide is the main part for vertical movement, connected to the frame by sliding or rolling. The bed is a sturdy worktable that ensures stability during operation.

Comprises the base, column, mechanical arm, and hydraulic cylinder. The frame supports and stabilizes the entire machine, ensuring strong stability and rigidity. The slide is the main part for vertical movement, connected to the frame by sliding or rolling. The bed is a sturdy worktable that ensures stability during operation.

Drive Mechanism:

Transmits power to the working components via mechanical, hydraulic, or pneumatic methods. The drive usually includes a motor, reducer, clutch, and gear system to provide the necessary power and force for movement.

Transmits power to the working components via mechanical, hydraulic, or pneumatic methods. The drive usually includes a motor, reducer, clutch, and gear system to provide the necessary power and force for movement.

Working Parts:

Mainly consists of the punch, guide pillar, and pull rod.

Mainly consists of the punch, guide pillar, and pull rod.

Control System:

Controls operation, stopping, and automatic adjustments via electrical or hydraulic means. It consists of electrical components, hydraulic parts, and computers to monitor and control operation parameters, ensuring accuracy and stability during punching.

Controls operation, stopping, and automatic adjustments via electrical or hydraulic means. It consists of electrical components, hydraulic parts, and computers to monitor and control operation parameters, ensuring accuracy and stability during punching.

Types of Perforated Sheet Machines

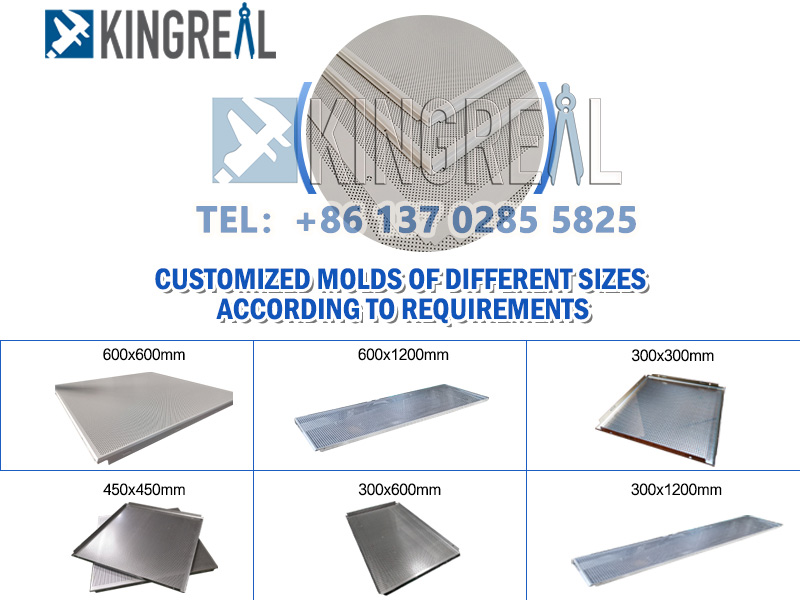

Sheet metal perforating machines can be categorized into single-head and multi-head types based on the number and structure of punches. Single-head machines are suitable for small batch production, while multi-head machines are ideal for large-scale production. Additionally, there are manual and automatic perforated punching machines, allowing selection based on production needs.

Advantages of Perforated Punching Machines

Perforated sheet machines offer advantages such as simplicity, high processing speed, quality holes, and low costs. Compared to traditional drilling and cutting methods, they enable mass production, enhance efficiency, and ensure consistency and precision of holes.

Application Areas of Punching Machines

Punching machines are widely used in automotive manufacturing, electronics, construction, and home appliance industries. In automotive manufacturing, they create holes in body panels for component installation; in electronics, they produce ventilation and connection holes in casings; and in construction, they make mesh and railings.

Development Trends of Sheet Metal Perforating Machines

With increasing industrial automation, perforated sheet machines are continually evolving. Future trends include digitization, intelligence, and efficiency. By incorporating automated control systems, they can operate autonomously in production lines, improving efficiency and quality. Additionally, advancements in materials science will allow perforated punching machines to accommodate various processing needs.

In summary, as a crucial mechanical processing device, the perforated punching machine has broad applications and clear advantages. With ongoing industrial advancements, perforated sheet machines will continue to develop and innovate to meet changing market demands. They will play an important role in providing efficient and precise solutions across industries.

If you have any questions, feel free to contact KINGREAL CEILING MACHINERY!