What is linear ceiling?

Time:2024-08-30

Views:197

Linear ceiling panels are a new combination of linear strips and ceilings, adding distinctive features to modern architecture. As a contemporary architectural decorative material, they have gradually gained attention due to their unique structural and design concepts. These panels are produced by a linear strip ceiling roll forming machine using processes such as uncoiling, flattening, forming, and cutting. This article will provide you with an overview of linear ceiling panels.

Introduction

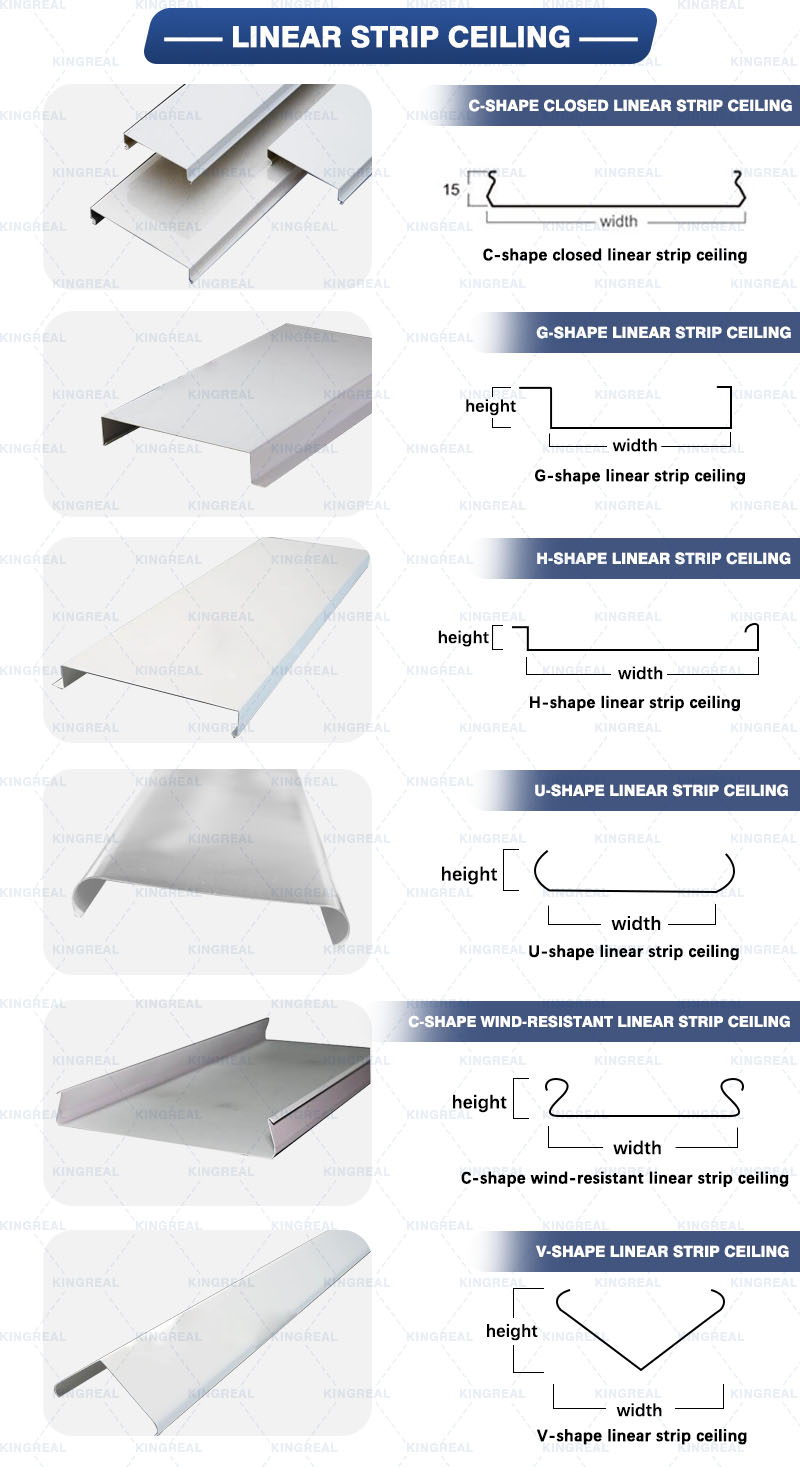

Linear ceilings are available in flat and perforated types, with characteristics such as anti-corrosion, fire resistance, moisture resistance, and ease of cleaning. They can be produced up to 6 meters in length and can be custom-sized. The aluminum panels conform to international standards like 1001H24 and 3003H24. The seamless integration of the panel surfaces and lines creates an elegant and aesthetically pleasing installation, offering a comfortable and relaxing atmosphere. During installation, different widths and curvatures of strips can be mixed and matched according to the designer‘s vision, allowing for a variety of design changes and functional effects. The shapes of the panels can vary based on design requirements and aesthetic effects, with common types including C-shaped, G-shaped, F-shaped, B-shaped, S-shaped, and more. The panels can be assembled without gaps, with all aluminum panels tightly connected. The aluminum panels are fixed onto the keel teeth and can be individually removed. This product is suitable for various building decorations, especially for indoor spaces like bedrooms, kitchens, bathrooms, and corridors.

Advantages of Aluminum Linear Ceiling Panels

1. Good Rigidity and Light Weight

Aluminum linear ceilings offer good rigidity, are lightweight, and have high strength. They are highly resistant to corrosion, with fluorocarbon paint that lasts up to 25 years without fading.

Aluminum linear ceilings offer good rigidity, are lightweight, and have high strength. They are highly resistant to corrosion, with fluorocarbon paint that lasts up to 25 years without fading.

2. Excellent Craftsmanship

The panels use a process of pre-processing followed by painting, allowing for complex geometric shapes, including flat, curved, and spherical surfaces.

The panels use a process of pre-processing followed by painting, allowing for complex geometric shapes, including flat, curved, and spherical surfaces.

3. Ease of Cleaning and Maintenance

The panels are resistant to staining, with a non-stick paint film that prevents contaminants from adhering, making them easy to maintain.

The panels are resistant to staining, with a non-stick paint film that prevents contaminants from adhering, making them easy to maintain.

4. Convenient Installation

The panels are pre-formed in the factory, requiring only simple fixing on-site without the need for cutting.

The panels are pre-formed in the factory, requiring only simple fixing on-site without the need for cutting.

5. Recyclable and Environmentally Friendly

Aluminum panels are 100% recyclable, offering high recycling value and benefiting the environment.

Aluminum panels are 100% recyclable, offering high recycling value and benefiting the environment.

6. Uniform Coating and Diverse Colors

The panels feature uniform coating and a wide range of colors, providing ample choices.

The panels feature uniform coating and a wide range of colors, providing ample choices.

Value of Indoor Aluminum Linear Ceiling Panels

When aluminum linear ceilings were first introduced, the choice of materials such as iron, steel, and copper was considered from a scientific perspective. Although iron is cost-effective, it is prone to rust. Copper and steel, while better, increase costs without necessarily improving installation results or performance compared to aluminum. Aluminum offers a lower cost and superior surrounding properties, including excellent corrosion resistance. However, to enhance aesthetics and richness, aluminum linear ceiling panels undergo various metal surface treatments. The market offers various colors and surface treatment techniques for these panels. The main surface treatments for aluminum linear ceiling panels include spraying, rolling, and film coating. Spraying is commonly used in projects, while rolling is less favored unless it has brand advantages. Aluminum, being a lightweight and clean metal, cannot match the strength of iron, steel, or copper. The material composition for aluminum linear ceilings includes magnesium and manganese. Adding manganese increases material rigidity, while magnesium enhances flexibility and rebound.

When choosing aluminum linear ceiling panels, price considerations are crucial. Typically, edges and custom shapes are calculated separately, and labor costs may also be separately calculated. If installation costs are included, this should be clarified! When issuing an order, ensure that the sales representative specifies all details clearly.

Installation Instructions

Taking the C-shaped linear ceiling panel as an example:

1. Install aluminum edge trims at the same horizontal height.

2. Install suspension rods and light steel keels at appropriate intervals. The rod spacing should be ≤1.2 meters, and the keel spacing should be 1.2 meters.

3. Attach the suspension components pre-installed on the triangular keels to the light steel keels perpendicularly, adjust to ensure level alignment.

4. Insert the two parallel edges of the square panels into the triangular keel gaps. After aligning the two ends of the panel, progressively press and align each row of panels, adjusting as needed to ensure the panels are flat and the gaps are vertical. (Note: The side with small pits on the square panel should be inserted into the triangular keel gap.)

5.Wear gloves during installation. If any marks are left on the panel surface, clean them with water. Do not remove the protective film during installation.

We hope this article provides you with a deeper understanding of linear ceiling panels.