Advantages and uses of synchronous belt conveyor

Time:2021-02-19

Views:2801

When designing a feeder, the first thing to consider is the conveying medium to be used, which depends on the size, shape and weight of the product being processed, as well as process requirements, such as conveying distance and route, conveying speed and positioning accuracy. For assembly and automation applications, the most popular conveying media are belts, chains, flat top chains and power rollers.

Among these media choices, belts can be said to be the most versatile. They can be manufactured in almost any width, can span long conveying distances, they operate with lower noise and require less maintenance than chains or rollers. The belt and its matching rollers (or pulleys) also have many different materials and finishes to meet specific application requirements and environmental conditions.

The traditional belt-driven feeder uses a flat belt and relies on the friction between the belt and the roller to transmit power. They also rely on the friction between the belt surface and the product to fix the product in a specific position on the feeder. This friction-based design is flexible and economical, but it can lead to potential changes in product positioning and positioning. For example: if the working conditions exceed the rated load, speed or acceleration, the belt may slip on its drive roller, and the product will move or slide on the belt during start and stop or any acceleration changes.

When accurate product position and direction are required, timing belt feeder is usually the best choice.

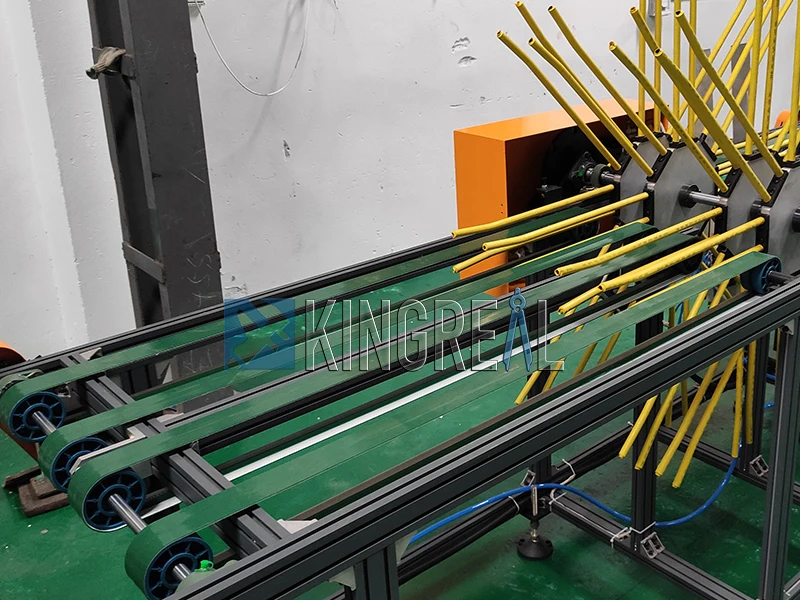

Timing belt is also called timing belt or toothed belt. The timing belt has a tooth surface that meshes with a matching toothed pulley. This positive meshing between the belt and the pulley, plus the pretension (the force exerted on the belt along the direction of movement) eliminates the problem of belt slippage. Timing belt feeders usually use belts reinforced with steel tensile ropes to provide higher load-bearing capacity and achieve high acceleration rates without causing the belt to stretch (this will cause the belt to bear greater force) .

In order to improve the grip, the top (carrier) side of the belt can be coated to increase the friction between the product and the belt surface and reduce the possibility of the product sliding on the belt. The pulley material and finish can also be selected to meet specific application requirements and environmental conditions, such as anti-static compatibility, food grade or clean environment.

When the application requires the product position to be very precise and the position is not lost, the splint or fixing device can be connected to the surface of the belt frame to fix the product in a specific position and have the correct direction.

Another option to ensure precise location and orientation is to transport products on pallets. Positioning the product on a fixed pallet, coupled with the precise, non-slip conveying of the timing belt, can provide the highest level of position accuracy and certainty.

Another benefit of the timing belt feeder is that the movement of multiple feeders-therefore, the conveyed products-can be synchronized. This makes the timing belt design ideal for dual or multi-line configurations and allows large, heavy loads to be transported, even when precise positioning is required.