Video Display

Video Display  Complete Blanking Line Machine Solution

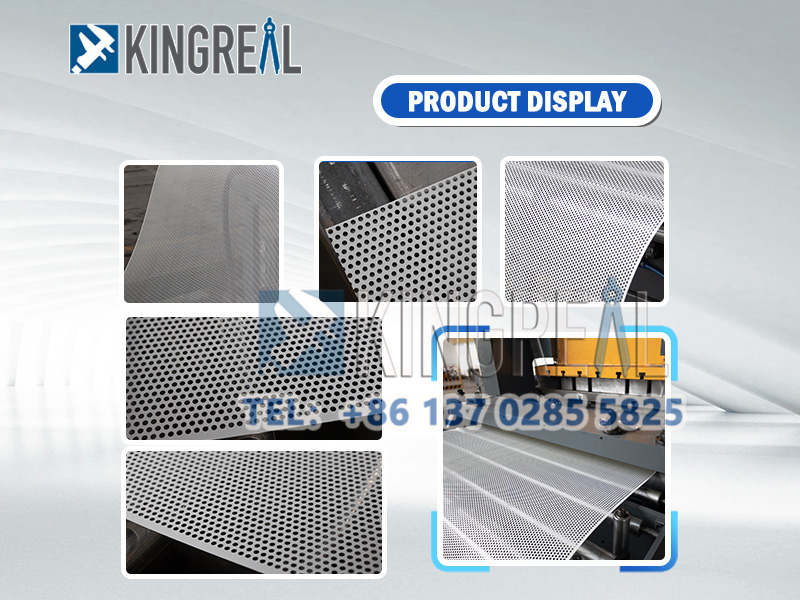

Complete Blanking Line Machine Solution KINGREAL full automatic blanking line machine is used for perforating different materials metal coil or panel with high speed and high precision. The hole types and specification are adjustable.

Perforated metal coil is widely used in industrial. For example, baguette pan, metal filter, acoustic wall panel before roll forming, the raw metal coil must be perforated. To meet the production needs of perforated - cutting / rewind, Kingreal provide a complete blanking line machine solution, the metal perforation line can be equipped with a rewinder, which can help you rewind the perforated coil and send to the roll forming process easily.

Application of Perforated Metal Coil

Application of Perforated Metal Coil

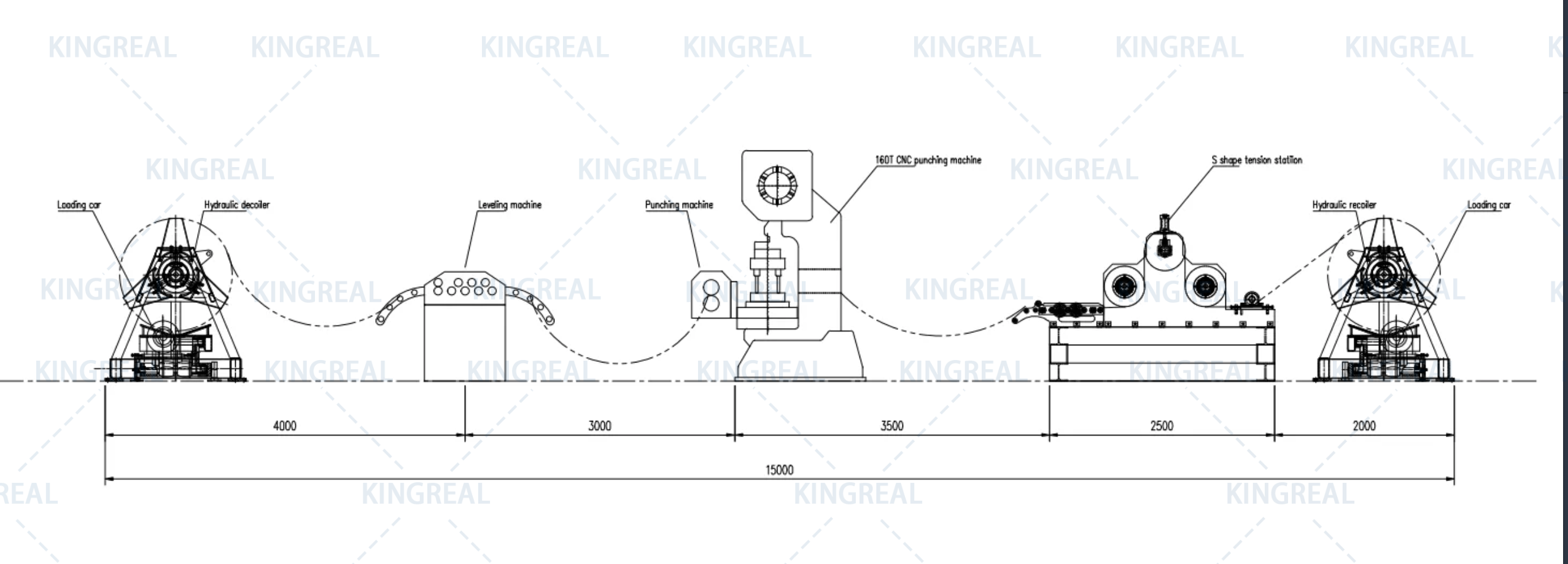

Main Processes of Coil Blanking Line

Main Processes of Coil Blanking Line Loading coil - Decoiler - Straighten - Punching - Feeder - Cutting / Rewinding

Main Components of Blanking Line Machine

Main Components of Blanking Line Machine

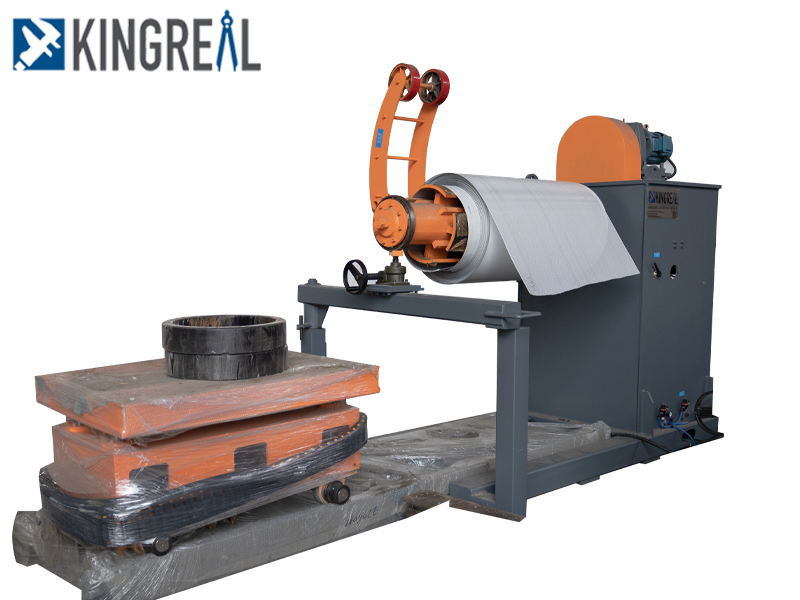

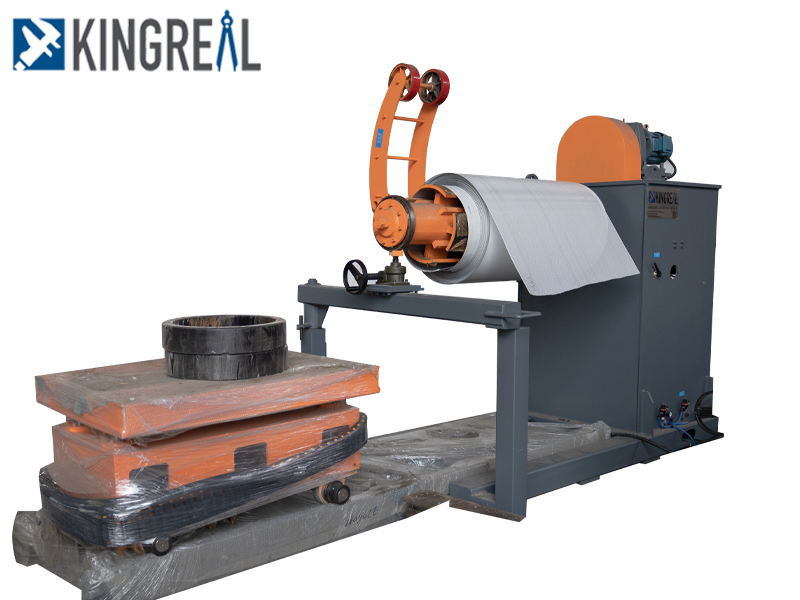

Decoiler

|

Leveler

|

Metal Punching Machine

|

Feeder

|

Coil Cutting Machine

|

Rewinder

|

Technical Specs

Technical Specs | Capacity | 1600kN |

| Nominal Stroke | 3mm |

| Slide Stroke | 20mm |

| SPM | 160-220 |

| Max. Die Height | 420mm |

| Die Height Adjustment | 50mm |

| Main Motor Power | 18.5KW |

| Air Pressure | 0.5mm |

What KINGREAL Metal Perforating Machine Can Provide

What KINGREAL Metal Perforating Machine Can Provide | 1.Rewind Design KINGREAL is able to customize blanking line production solutions according to customer’s requirement. KINGREAL also can provide complete metal punching machine production solution, the blanking line can equip with a rewinder. The perforated coils can be wound up and send to the roll forming process. The rewined coil can roll forming to metal acoustic wall panel, aguette pan, metal filter, and etc.. |

|

|

2.High Precision KINGREAL metal perforating machine adopts pneumatic brake system makes the perforation more accurate and stable. |

| 3.Multiple Choice The hole types, feed material and apertures can be chosen. Hole types: The metal hole punch press can punch the coil or plate into round holes, square holes, hexagonal holes, and other hole shapes. Feed material: The raw material can be aluminum sheet, galvanized steel sheet, stainless steel sheet, and etc.. Aperture: You just need to set the parameters on the electronic control system than the blanking line machine can punch automatically. |

|

Details of Metal Perforating Machine

Details of Metal Perforating Machine Material: KINGREAL high speed metal perofrating machine adopts DC53 blade material as the die, which can upgrade the precision and service llife of the punching press machine.

Speed: The punching speed is 160-220 strokes per minutes (adjustable).

Precision: Eight rows of aluminum holes and four rows of iron holes can be punched each time, it is really fast.

Adaptability: The metal perforating machine can be matched with any automated production requirement to improve production efficiency and reduce cost.

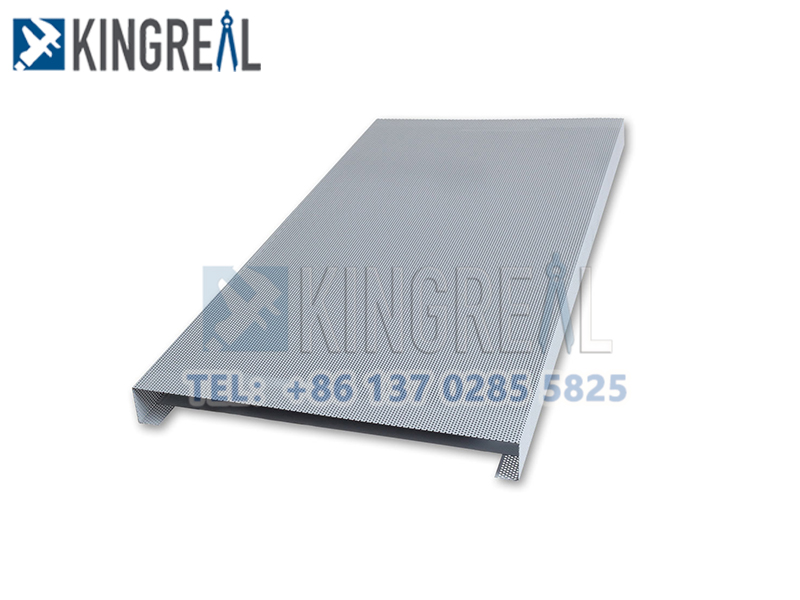

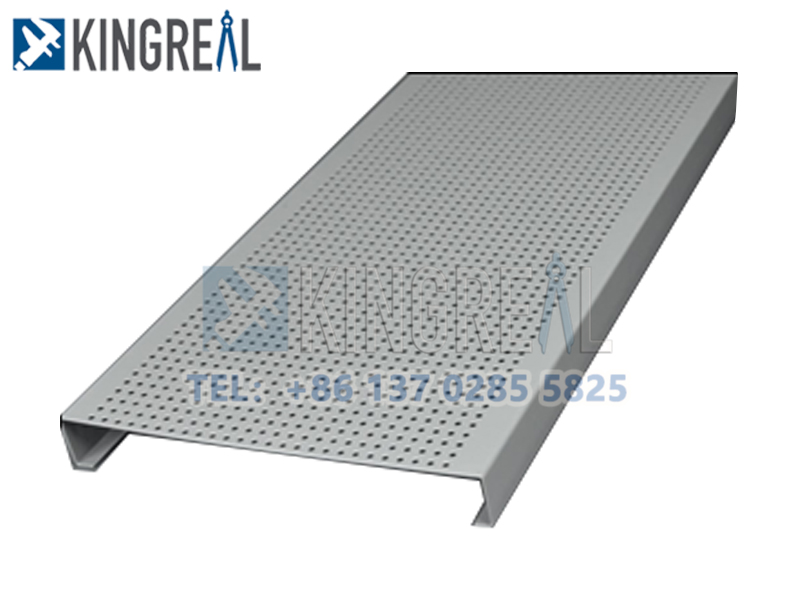

About Metal Acoustic Wall Panel

About Metal Acoustic Wall Panel

These panels are a practical solution for managing acoustics in various environments, contributing to both the functionality and aesthetics of a space. Besides, Kingreal blanking line machine is literally the best choice for producing acoustic metal sheets for walls.

After-Sales Services

After-Sales Services

Services are always highly considered by us, in addition to establishing a complete remote service system, localized after-sales service is also what we have been insisting on doing. The global localization service point is under construction.

KINGREAL in Diverse Exhibitions

KINGREAL in Diverse Exhibitions

About Metal Acoustic Wall Panel

About Metal Acoustic Wall Panel Metal acoustic wall panels offer several advantages and have a wide range of applications.

Here are some key benefits:

Noise Insulation: They control and improve the noise and sound of a space, effectively insulating it from noise.

Sound Absorption: Acoustic panels absorb sound waves, reducing echo and reverberation, which enhances sound clarity and intelligibility.

Increased Privacy: By preventing sound leakage, they help maintain privacy within a space.

Aesthetic Appeal: They can be aesthetically pleasing and are available in various designs to complement interior decor.

Increased Productivity: In workspaces, they can increase productivity by creating a quieter environment that minimizes distractions.

|

|

|

|

Applications of metal acoustic wall panels are diverse, including:

Recording Studios: For clear sound recording without interference from echoes.

Auditoriums and Classrooms: To ensure clear communication and reduce noise distractions.

Offices: To create a conducive working environment by controlling sound levels.

Commercial Buildings: To enhance the overall acoustic quality of the space for comfort and functionality.

These panels are a practical solution for managing acoustics in various environments, contributing to both the functionality and aesthetics of a space. Besides, Kingreal blanking line machine is literally the best choice for producing acoustic metal sheets for walls.

After-Sales Services

After-Sales Services Services are always highly considered by us, in addition to establishing a complete remote service system, localized after-sales service is also what we have been insisting on doing. The global localization service point is under construction.

KINGREAL in Diverse Exhibitions

KINGREAL in Diverse Exhibitions