Video Display About Sheet Metal perforation Production Line:

Video Display About Sheet Metal perforation Production Line:

Kingreal CEILING MACHINERY Sheet Metal Perforating Machine Successful Cases

Kingreal CEILING MACHINERY Sheet Metal Perforating Machine Successful Cases

Diverse Metal Sheet Punching Machine

Diverse Metal Sheet Punching Machine

As one of the most professional manufacturer of metal processing machines in China, KINGREAL CEILING MACHINERY has Successfully designed different types of perforated machines to meet different production needs. KINGREAL CEILING MACHINERY also provides customized services, the details welcome to contact us!

Description of Metal Sheet Punching Machine

Description of Metal Sheet Punching Machine

KINGREAL CEILING MACHINERY metal perforation production line is used for producing different kinds of perforation panels, raw materials can be stainless steel, alloy aluminum and galvanize steel. The feed material can be coil or cutter steel material.

Main structure of the metal perforation panel can be designed according to customers’ requirements. The raw material can be coil or cut steel piece. Basic procedure of the perforated metal machine production line is uncoiler, servo feeding, metal punch press, then recoil the material. Also we can change the dies of the metal punch press to produce different type of metal plate with holes.

Equipment Composition:

Equipment Composition:

|

1. Hydraulic Decoiler 2. Precision Straightener 3. Servo feeder 4. High-speed metal punch press 5. Cutting station |

|

KINGREAL CEILING MACHINERY will configure corresponding production equipment according to your production needs to ensure machine production.

Technical Specification

Technical Specification

| Maximum stamping width | 1.25m |

| Punching speed | 45-70 times/min |

| Maximum stamping thickness | 2.0mm |

| Aspect | 2500x1800x2000mm |

| Control way | digital control |

| Power | 7.5kW |

| Weight | 5500kg |

Advantages of Sheet Metal Perforating Machine:

Advantages of Sheet Metal Perforating Machine:

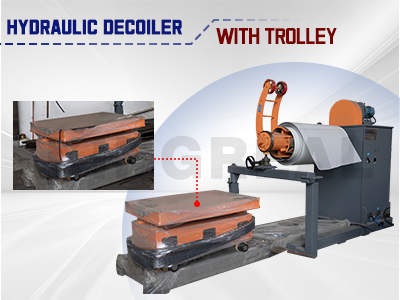

| Hydraulic Decoiler With Trolley KINGREAL CEILING MACHINERY provides a loading trolley for you to equip in the hydraulic decoiler, so that you can achieve highly automated metal coil loading. No excessive manpower operation is required, just simple operation of the machine can complete the loading process, providing convenience for your metal punching operation from the beginning. |

|

|

High Speed Metal Sheet Punching Machine As a professional metal sheet punching machine manufacturer, KINGREAL CEILING MACHINERY can provide metal punch press machine of different tonnages, the most common ones are 125 tons, 160 tons and 200 tons. KINGREAL CEILING MACHINERY uses pneumatic brake system and high-hardness sheet metal punching die to build the machine, which have the advantages of both precision and high speed, and the SPM can reach 180 or even higher. It is your first choice for metal punching. |

| Perforated Metal Panel Cutting Device The sheet metal perforating machine is equipped with a cutting station. The punched metal sheet can be directly cut into the size you need and then sent to the next process or directly packaged and sold on the market. The cutting blade is refined from high-hardness materials, with fast cutting speed and smooth cutting surface without burrs. |

|

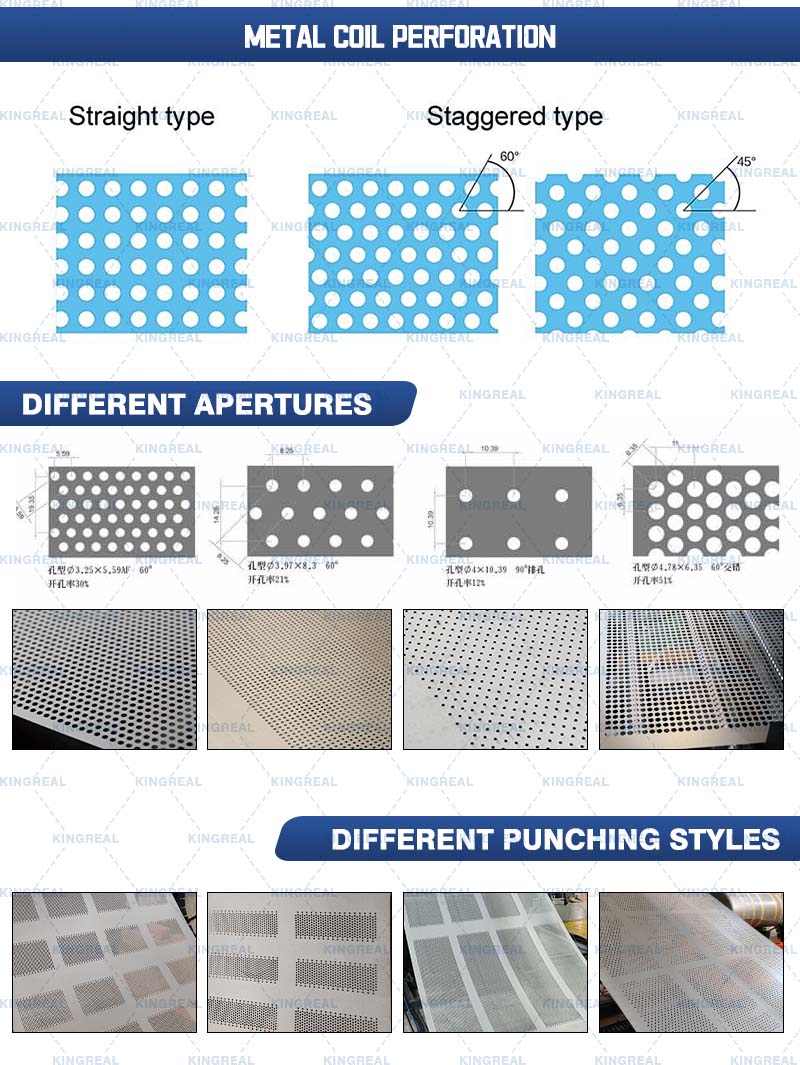

Different Hole Types Perforated by KINGREAL CEILING MACHINERY Metal Sheet Punching Machine

Different Hole Types Perforated by KINGREAL CEILING MACHINERY Metal Sheet Punching Machine

Application Areas of Perforated Sheet Metal:

Application Areas of Perforated Sheet Metal:

The most common field of use for perforated metal is the construction industry. As we know, the perforated sheet metal has been used in architecture for hundreds of years. Such as the perforated metal ceiling tile can not only increase the aesthetic value of the building but also absorb noise, which is deeply loved by consumers.

In addition, based on the characteristics of punched metal, it is also made into different shapes and widely used in food production, retail display and used to control the noise.

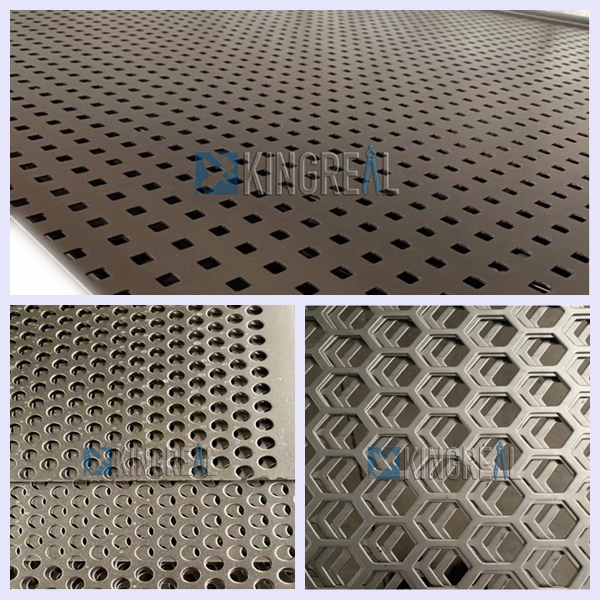

Different Hole Types As You Need:

Different Hole Types As You Need:

|

Round hole perforated Square hole perforated Slotted hole perforated Hexagonal ( honeycomb ) perforated Ornamental& decorative perforated |

|

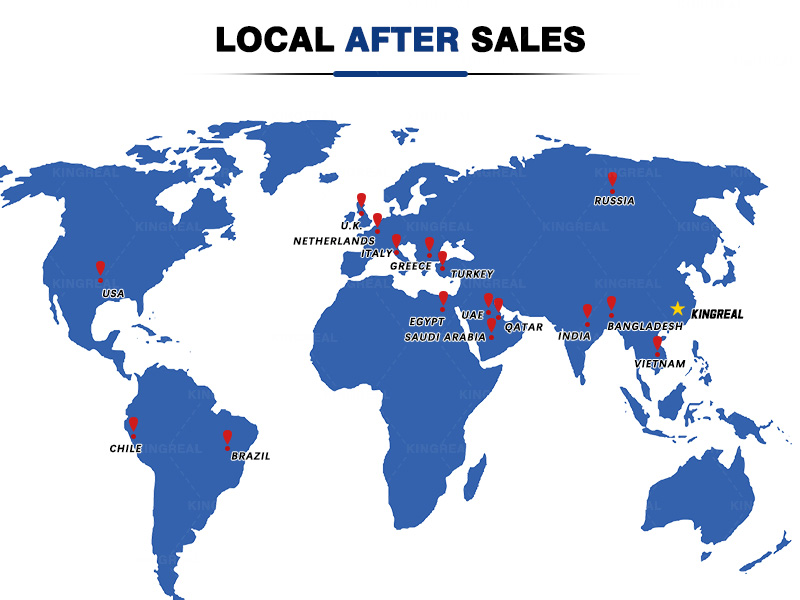

Installation Service

Installation Service

KINGREAL CEILING MACHINERY in Canton Fair

KINGREAL CEILING MACHINERY in Canton Fair