What Is Acoustic Rock Wool Sandwich Panel?

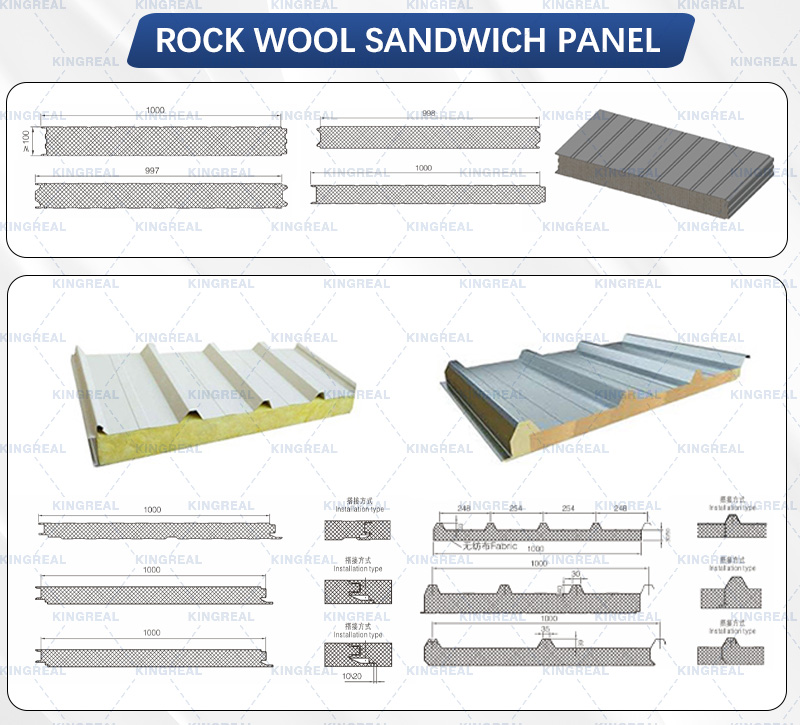

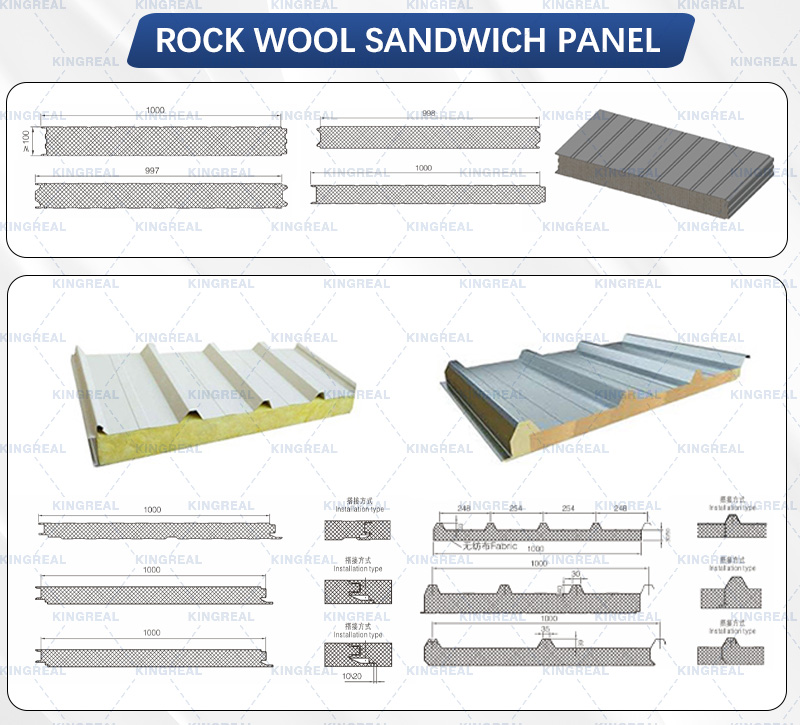

What Is Acoustic Rock Wool Sandwich Panel?Perforated rock wool sandwich panel is a composite panel made of two layers of metal plate sandwiched by rock wool material. Perforation refers to a series of small holes or holes made in a metal plate by stamping or punching machinery.

Perforated rock wool sandwich panel through the punching process to create a hole structure, not only can reduce weight, increase ventilation and air permeability and aesthetic decoration, but also improve the sound insulation effect, so that it is widely used in the field of construction.

How To Produce The Acoustic Coil?

How To Produce The Acoustic Coil?

How To Produce The Acoustic Coil?

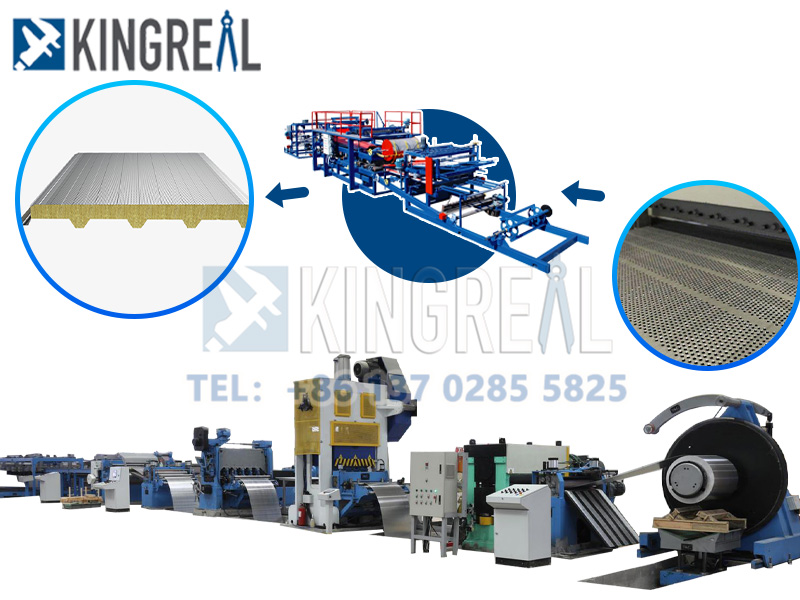

How To Produce The Acoustic Coil?KINGREAL Coil Punching & Winding Line is a production line equipment for producing perforated metal sheets, which is one of the most popular equipment recently. It usually consists of coil feeding system, punching machine, winding system and other components.

The coil feeding system is used to feed the metal coil into the production line, and after coil leveling, positioning and other processes, the coil is fed into the punching machine. The punching machine is used to punch holes in the metal coil, creating a series of small holes or holes in the metal coil through stamping or punching machinery to form a perforated metal sheet. Finally, the winding system winds the perforated and processed sheet metal into coils, ready for subsequent processing and use.

Main Component For Acoustic Panel Production Line

Main Component For Acoustic Panel Production Line

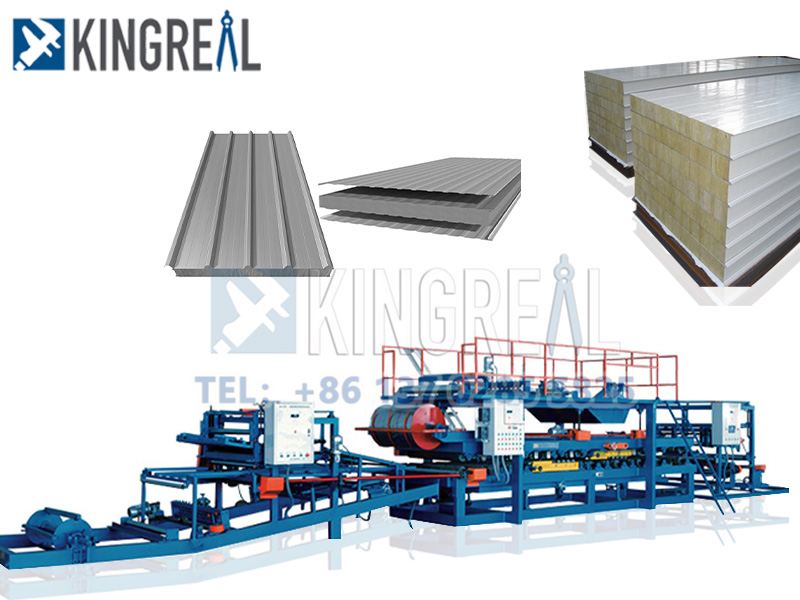

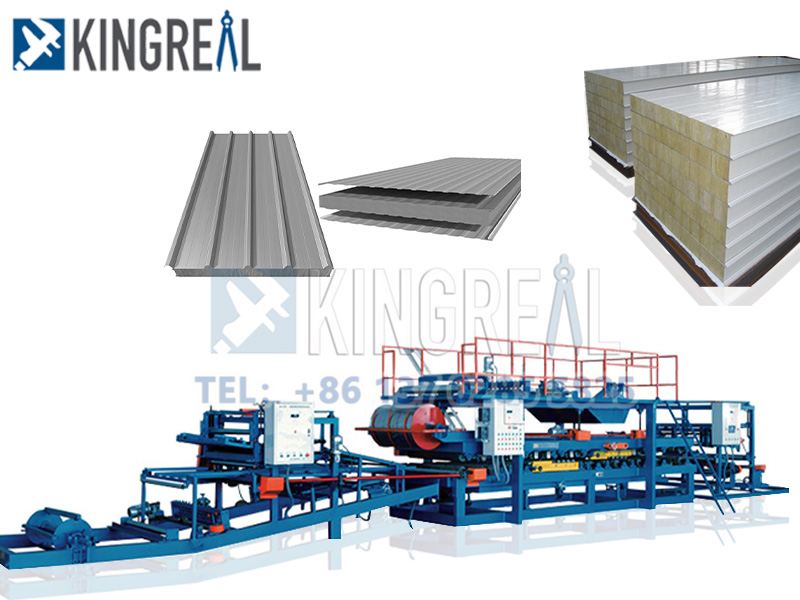

Acoustic Rock Wool Sandwich panel Production Line

Acoustic Rock Wool Sandwich panel Production Line

Main Component For Acoustic Panel Production Line

Main Component For Acoustic Panel Production Line|

- Mechanical Decoiler

A mechanical tool called metal uncoiling equipment is primarily used to unroll metal materials into sheets with specific widths and thicknesses. Operating, adjusting, supporting, and driving parts are among its primary parts.

|

|

|

-Fast-moving Punching Device

One type of machine used for processing and punching metal plates is the metal plate punching machine. It is primarily made up of the operation control system, punching unit, driving system, etc. It can accomplish high efficiency punching processing and be applied to a range of processing procedures, including concave, convex, open hole, and composite processing.

|

Acoustic Rock Wool Sandwich panel Production Line

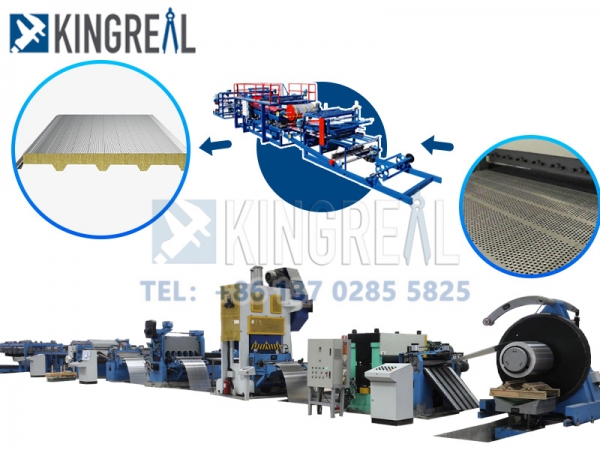

Acoustic Rock Wool Sandwich panel Production LineA type of composite material board called a rock wool sandwich panel is composed of two metal plate layers sandwiched between a layer of rock wool material. Excellent thermal insulation and fire performance make rock wool sandwich panels popular in cold storage, industrial equipment, and building, among other industries.

The KINGREAL Continuous Rock Wool Sandwich Panel Production Line is a comprehensive line that includes Acoustic Panel Production Line

foam reinforcement, a panel sprayer, a conveyor system for rock wool material, a sandwich panel roll forming machine, and numerous other pieces of equipment.

Sandwich Production Line Specification:

Sandwich Production Line Specification:

What Our Production Can Do?

What Our Production Can Do?

Contact Us Now!

Contact Us Now!

Sandwich Production Line Specification:

Sandwich Production Line Specification:| Working Speed | 4000M/Min |

| Machine Length | About 70M |

| Working Height | 1050MM |

| Control Way | PLC Control |

| Total Power | 45KW |

| Control Voltage | 220V |

What Our Production Can Do?

What Our Production Can Do?

Contact Us Now!

Contact Us Now!