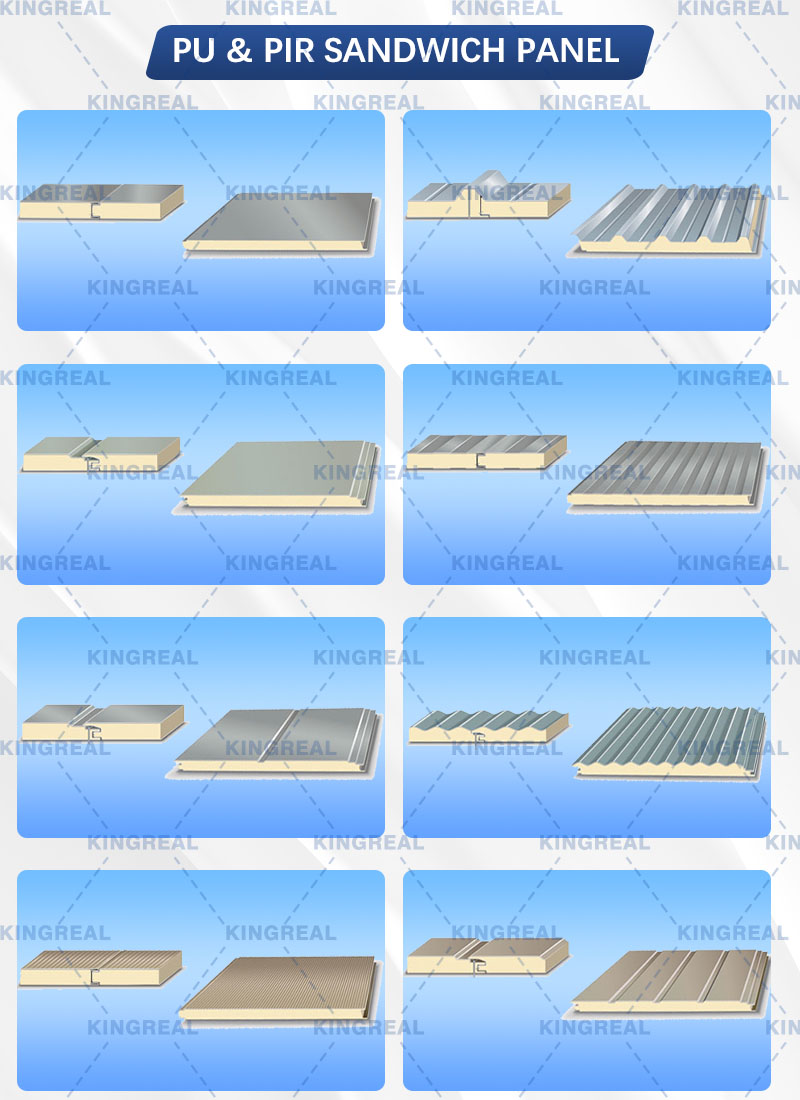

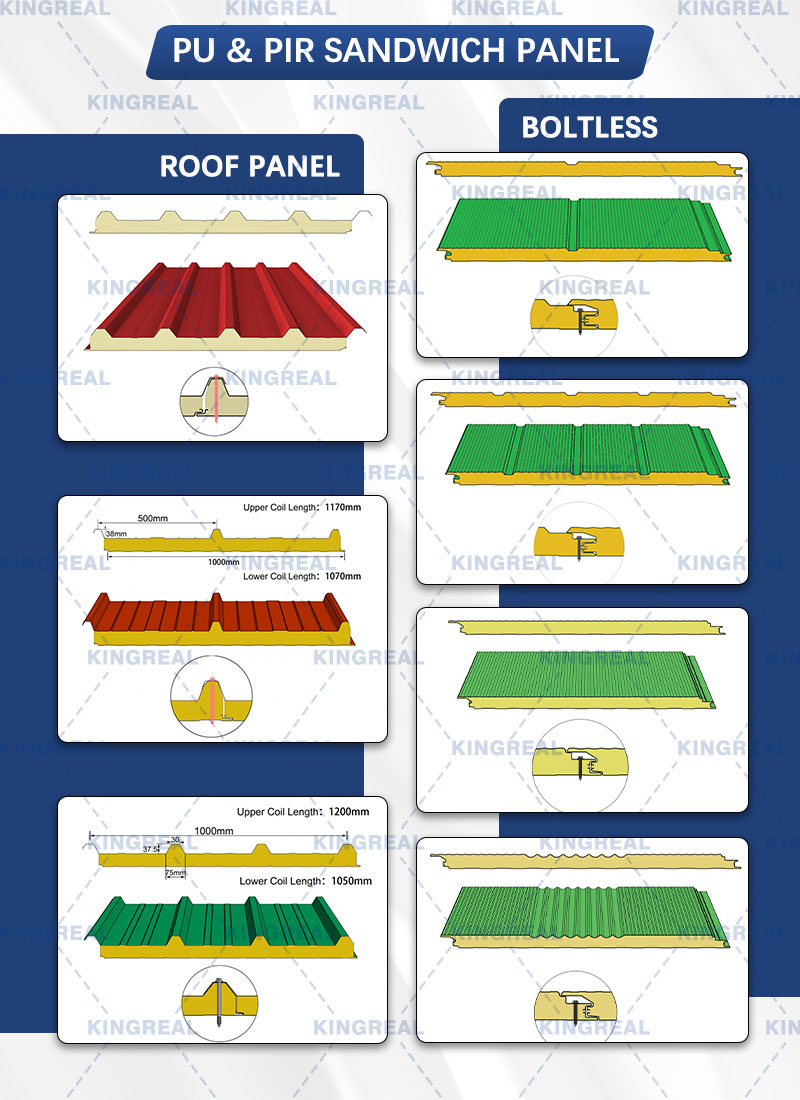

What Is PU Sandwich Panel?

What Is PU Sandwich Panel?PU sandwich panel is a kind of sandwich panel made of polyurethane (Polyurethane) foam material, also known as polyurethane sandwich panel. It consists of a layer of polyurethane foam sandwiched between two layers of metal sheets. Polyurethane foam material has good thermal insulation, heat insulation and sound absorption properties, so PU sandwich panel has excellent thermal insulation effect.

Machine Description:

Machine Description:In order to meet the needs of factories in different industries for the production of PU laminates, KINGREAL specializes in the production of PU Continuous Sandwich Panel Production Line, which can realize efficient, continuous and auto production, improve production efficiency and product quality.

At the same time, the production line can also be customized according to customers’ needs, producing sandwich panels with different specifications, thicknesses and colors.

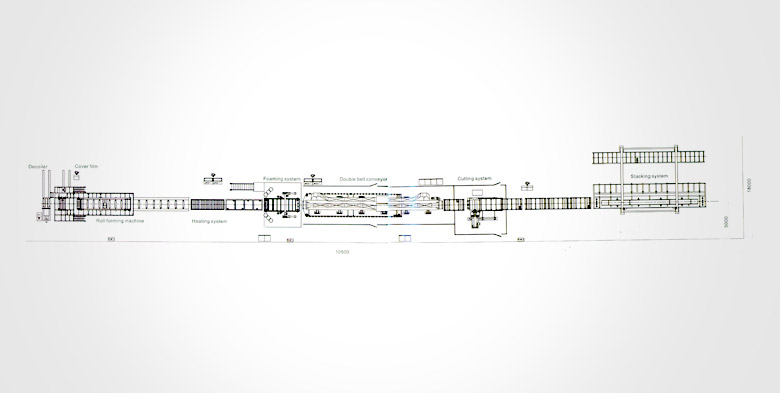

Working Process Of PU Continuous Sandwich Panel Production Line

Working Process Of PU Continuous Sandwich Panel Production Line

Sheet Coil Material Decoiler -- Filming Slitting And Cutting -- Main Roll Forming Machine For Sheet Panel -- Preheating Oven -- PU Foaming System -- Double Belt Curing System -- Band Saw Cutting System -- Cooling System -- Stacking System -- Packing System

Main Technical Specification

Main Technical Specification

|

Suitable Raw Material |

Type |

Color Steel/Stainless Steel/Aluminum Sheet |

|

Thickness(mm) |

0.4-0.8(Steel)/ 0.35-0.6(Stainless Steel) |

|

|

Width(mm) |

≤1250 |

|

|

Weight(T) |

10T(Max |

|

|

Core Material |

PU/PIR/Rock-wool |

|

|

Products Specification |

Panel Length(mm) |

2000-18000 |

|

|

Panel Width(mm) |

600-1200 |

|

|

Panel Thickness(mm) |

30-200/250 |

|

Production Speed(m/min) |

3-7(adjustable) |

|

|

Valid Length Of Double belt Conveyor(mm |

16000-40000 |

|

|

Work Pressure On Pouring Foam(Bar) |

150-200 |

|

|

Total Power(KW) |

200 |

|

Main Components Detail:

Main Components Detail:

1. Main Roll Forming Machine

The PU Continuous Sandwich Panel Production Line Roll Forming System incorporates a double head roll forming machine specifically designed for the production of upper layer profiles. This machine is equipped with two sets of forming rollers, ensuring efficient and precise shaping of the profiles.

Additionally, the upper roll forming machine is complemented by a guiding system, a transmission system, and a sturdy frame, all of which contribute to its seamless operation.

2. PU Foaming System

The accessories for the foaming system consist of the sheet transmission conveyor, adhesive tape sealing device, and sponge sealing device.

3. Double Belts System

The Double Belts System (DBL) serves as an effective solution to address the issue of foaming expansibility by ensuring its solidity and determining the panel thickness and production speed. The side belt, on the other hand, plays a crucial role in overcoming horizontal expansion, determining the panel width, and providing guidance to the panels.

PU Continuous Sandwich Panel Production Line Features:

PU Continuous Sandwich Panel Production Line Features:

High degree of automation: PU sandwich panel molding machine adopts PLC control system, which can realize automatic production, reduce manual operation and improve production efficiency.

High molding precision: the molding machine has precise temperature control and pressure control system, which can ensure the molding precision and stable quality of sandwich panel.

Product quality is guaranteed:

Product quality is guaranteed:

1. The production line adopts hot air circulation heating furnace to ensure the stability of PU material foaming and curing within the control range, ensuring high quality of the laminated panels;

2. adopting high pressure foaming system, even foaming, accurate measurement and high stability, environmentally friendly process for composite production.

Application:

Application:

Who Are We?

Who Are We?

After-Sale Service

After-Sale Service