Video About Metal Ceiling Production Line

Video About Metal Ceiling Production Line

Description Of Half Perforated Ceiling Tile Production Line

Description Of Half Perforated Ceiling Tile Production Line

KINGREAL High Speed Half Perforated Aluminum Ceiling Tiles Production Line is full automatic production which including the material feed, cutting, automatic turn, automatic distribution, bending forming and automatic stack system. The whole production line is easy to operate and need only one or two workers to operate.

For this production line, We can use it to produce 300mm*300mm perforated integrated ceiling tiles, 300mm*300mm plain ceiling tiles, 300*300mm half perforation ceiling tiles on this machine. And 300*300mm perforated ceiling tiles is very popular in Turkey. KINGREAL had successful designed and manufacture the full automatic 300*300mm perforated aluminum ceiling tile for our Turkey Customer.

Different Perforation Line

Different Perforation Line

Unique Design Of The Metal Ceiling Tile Production Line

Unique Design Of The Metal Ceiling Tile Production Line

Along with the market of home decoration rising, the clip-in vocation is more flourishing. The shape of clip-in is in square and strip mainly. At present the most popular is the clip-in in 300×300, the traditional process is that there are two punched device to be formed, it is slow and unsafe, the material wastage is big.

The full automatic aluminium clip-in equipment is needed to meet the requirement of vocation, KINGREAL Worked out the 1st full automatic aluminium clip-in ceiling tile production line in China in 2008 after we spent a year to research and design. It will be worked automatically out for finished aluminium clip-in in 300×300 with customer’s logo with the aluminium coil in 334mm on uncoiler, it will be convenient for customer to advertise. This is automatic turn device for the ceiling tile, after perforation the perforated plate may have spur on the top surface and it will influence the quality. That is why we turn the ceiling tile automatically to avoid this problem.

Advantage Of The Half Perforated Ceiling Production Line

Advantage Of The Half Perforated Ceiling Production Line

1. With this high speed and full automatic system, it can save a lot of labor cost and also it will enhance the final products quality.

Usually we use ceiling tile standard aluminum coil for the material, and there are two different types. One is painted aluminum and filmed material. The other is unpaited, and the final product will be painted and powder after the production finished.

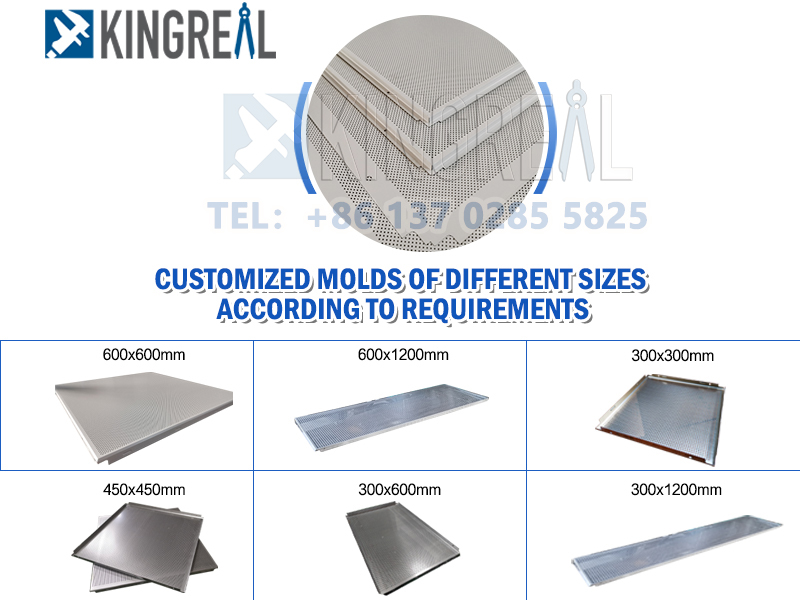

For 300*300mm aluminum ceiling tile, usually there is only one type - clip in 300mm*300mm ceiling tiles. Of course, we can customer make different other types and the just need to change the dies to production different types of ceiling plates.

2. The textile install machine can install the non-woven in the back of the perforated ceiling panel

- This is automatic distribution system to distribute the cutting panels on two ceiling tile bending forming machine.

- This is the automatic final ceiling tile stacker for this material.

- This is automatic distribution system to distribute the cutting panels on two ceiling tile bending forming machine.

- This is the full automatic material stacker for the final finished products, it will stack the finished ceiling tile one positive side and one reverse side. This automatic ceiling tile stacker will aviod the scratch of the panel surface also it will save time for the labors to pick up the material.

As following is the production video of the high speed 300mm*300mm square ceiling plate production line. It use perforated sheet as the raw material to cut the corners then bending forming.Other system is also available, welcome to inquiry us if any questions. We can customer design and make according to your requirements.

Final Product

Final Product

Quality Assurance

Quality Assurance

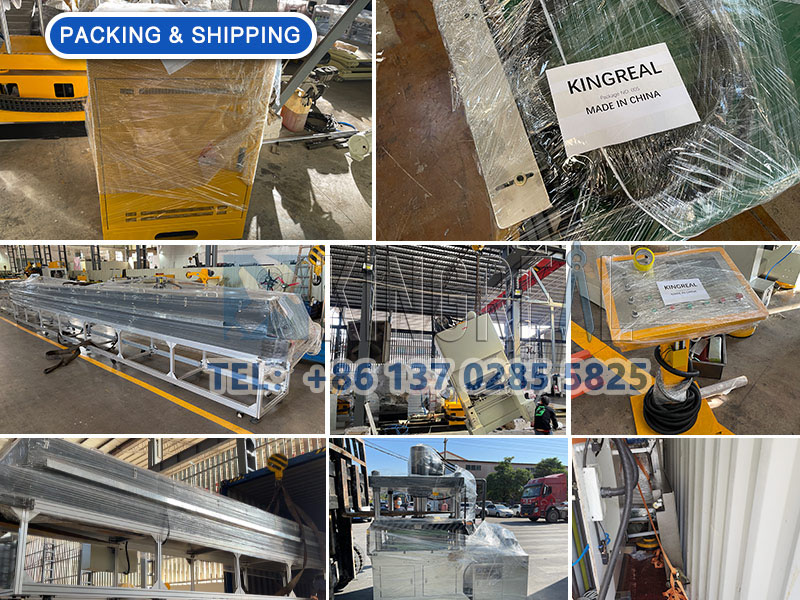

Packing & Shipping

Packing & Shipping

Our Factory

Our Factory