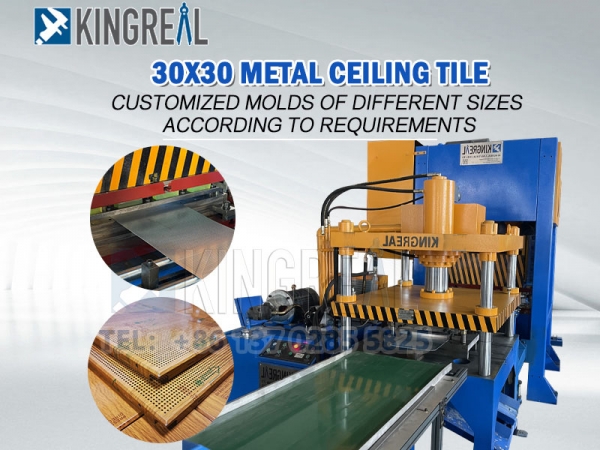

Video About 30*30CM Metal Ceiling Tiles Making Machine

Video About 30*30CM Metal Ceiling Tiles Making Machine

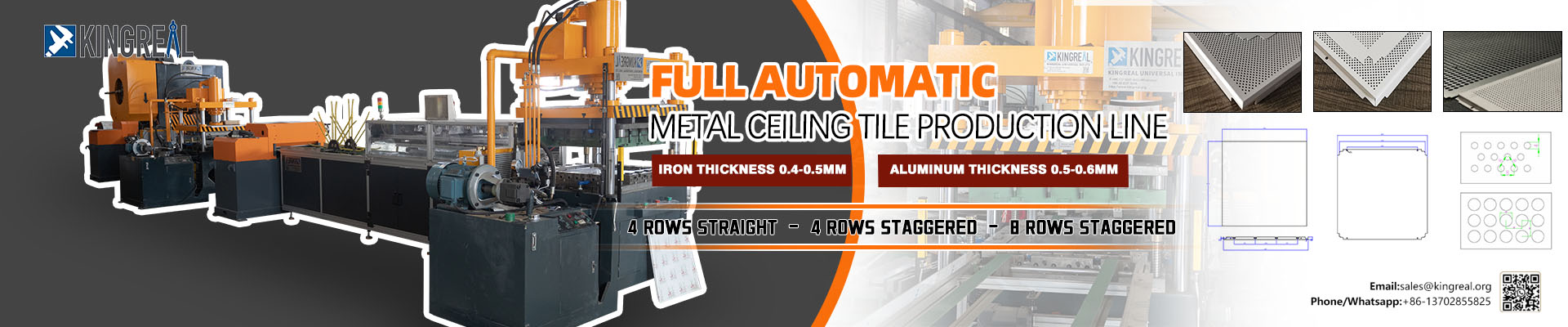

Description Of Metal Ceiling Panels Production Line

Description Of Metal Ceiling Panels Production Line

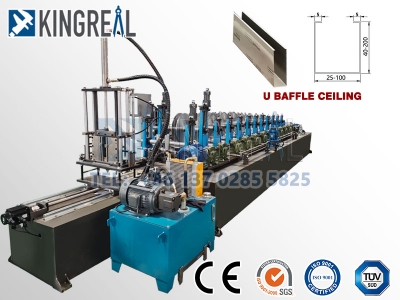

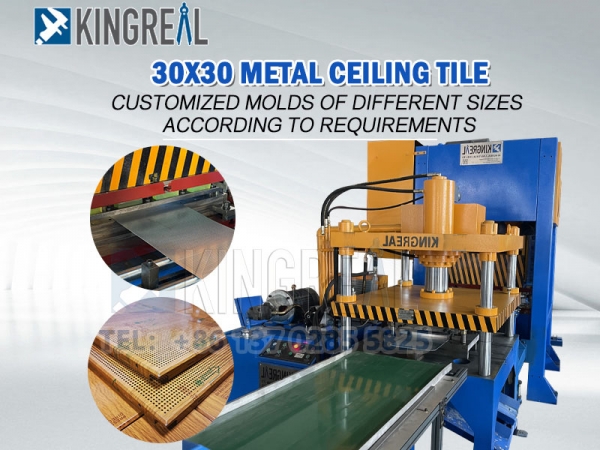

KINGREAL can provide perforated 300mm*300mm metal ceiling panels production line, also it can produce 300*300mm ceiling tile without perforation machine, for the plain ceiling tile, usually the raw material is cutted sheet, we will use a material feeder for the production.

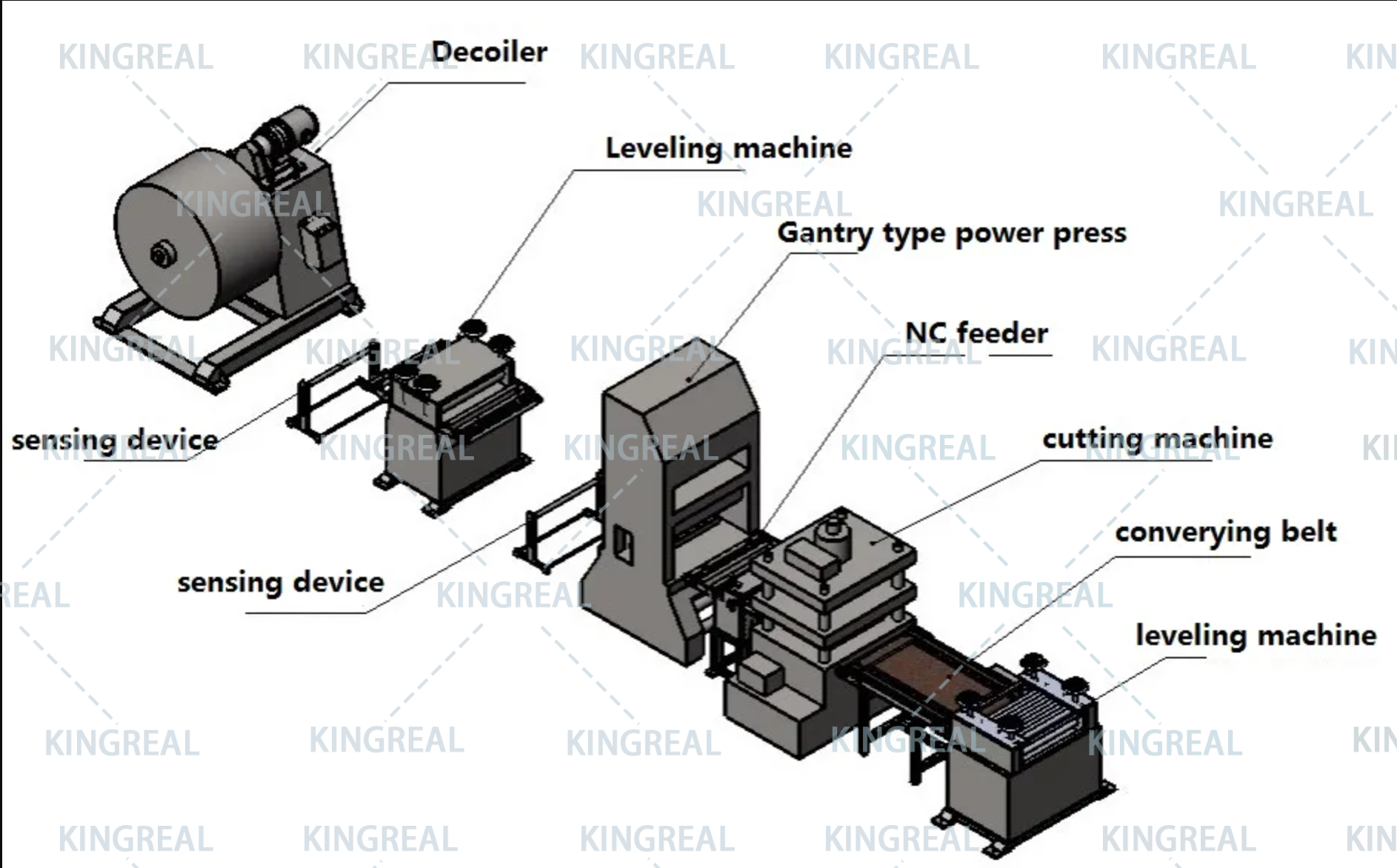

Our 300*300mm Suspended Metal Ceiling Panels Production Line is made of metal sheet feeder and forming machine, this machine can do the corner cutting and bending forming on the sane mould.

KINGREAL Unique Design

KINGREAL Unique Design

Along with the market of home decoration rising, the clip-in vocation is flourishing. The shape of clip-in is square and strip mainly. At present the most popular is the clip-in in 300×300, the traditional process is that there are two punched devices to be formed, it is slow and unsafe, and the material wastage is big.

The full automatic aluminum clip-in equipment is needed to meet the requirement of the vocation, KINGREAL Worked out the 1st full automatic aluminum clip-in equipment in China in 2008 after we spent a year to researching and designing. It will be worked automatically out for finished aluminum clip-in in ceiling tiles 300×300 with the customer’s logo with the aluminum coil in 334mm on uncoiler, it will be convenient for the customer to advertise.

This machine needs only one man to take the finished products on the machine. This will save a lot of labors cost especially when the labor cost gets more and more expensive. Even we have an automatic material stack for this machine, please contact us if you have any requests.

Advantages Of Metal Ceiling Tiles Production Line

Advantages Of Metal Ceiling Tiles Production Line

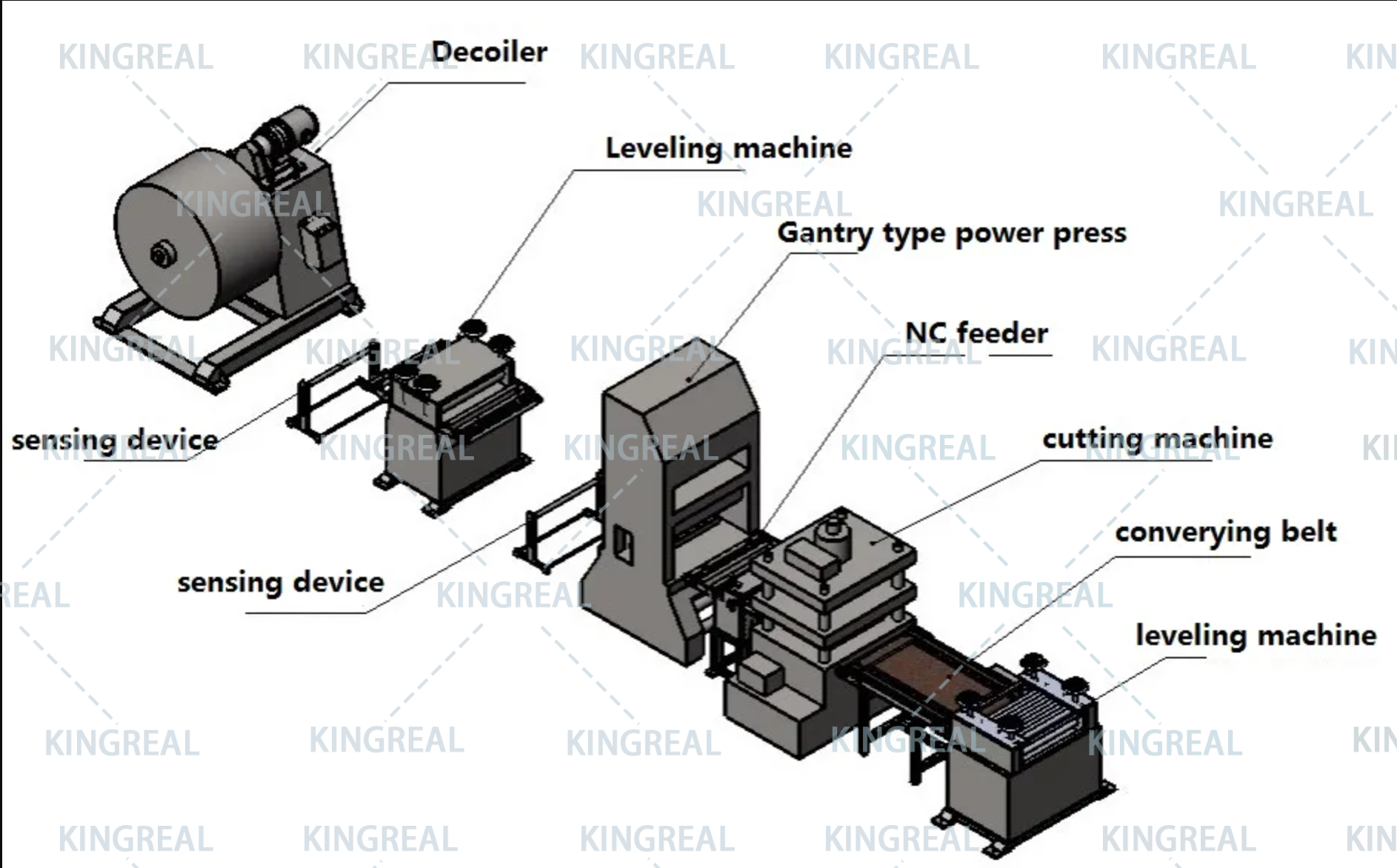

Fully Automatic Production Line

Utilizes self-developed automatic feeding robotic arms, automatic turning, and automatic stacking systems to achieve fully automated production of metal ceiling tiles. This machine features easy operation, smooth running, high output speed, and reduces the risk of workplace injuries.

Different sizes and types of ceilings can be produced

By changing the mold, the ceiling tile production line can produce 30x30cm, 60x60cm, 60x120cm and other sizes of tiles, and can also produce a variety of types of tiles such as clip-in, lay-in, and tegular. The replacement of the mold is very convenient, saving time and the cost of buying other machines.

Cost Reduction and Safety Improvement

The fully automatic ceiling production line is controlled by sensitive mechanical actions, eliminating the need for manual precision control. This reduces labor costs and minimizes safety risks associated with manual work.

Reduction of Waste

The hydraulic press performs one-step cutting of all four corners and bending of all four edges. This process reduces waste and saves costs.

Composition Of Complete Production Line

Composition Of Complete Production Line

Machine

Features

Amount

Decoiler

Hydraulic expansion

1 Unit

Pre-straightener

High-precision 19 Rollers

1 Unit

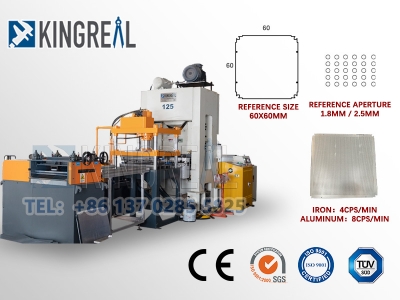

125 Tons High-Speed Perforation Press

125Tons, 100-150 SPM, 2-5PCS tiles/min

1 Unit

NC Servo feeding machine

Yaskawa Servo motor, 3.0KW High accuracy

1 Unit

Hydraulic notching & shearing press

60tons Hydraulic press, High accuracy

1 Unit

Transmission conveyor

Automatic

2 Units

Precision straightener

High-precision 21 Rollers

1 Unit

Automatic tiles flipping machine

For flipping 600*600 tiles 180 degrees

1 Unit

Automatic feeding mechanical arm

For feeding 600*600 tiles to next step production

1 Unit

Hydraulic bending forming press

For bending forming 600*600 tiles

1 Unit

Electric control system

Reliable parts

1 Unit

One Machine Can Produce Different Product

One Machine Can Produce Different Product

Description Of Metal Ceiling Panels Production Line

Description Of Metal Ceiling Panels Production Line

KINGREAL can provide perforated 300mm*300mm metal ceiling panels production line, also it can produce 300*300mm ceiling tile without perforation machine, for the plain ceiling tile, usually the raw material is cutted sheet, we will use a material feeder for the production.

Our 300*300mm Suspended Metal Ceiling Panels Production Line is made of metal sheet feeder and forming machine, this machine can do the corner cutting and bending forming on the sane mould.

KINGREAL Unique Design

KINGREAL Unique DesignAlong with the market of home decoration rising, the clip-in vocation is flourishing. The shape of clip-in is square and strip mainly. At present the most popular is the clip-in in 300×300, the traditional process is that there are two punched devices to be formed, it is slow and unsafe, and the material wastage is big.

The full automatic aluminum clip-in equipment is needed to meet the requirement of the vocation, KINGREAL Worked out the 1st full automatic aluminum clip-in equipment in China in 2008 after we spent a year to researching and designing. It will be worked automatically out for finished aluminum clip-in in ceiling tiles 300×300 with the customer’s logo with the aluminum coil in 334mm on uncoiler, it will be convenient for the customer to advertise.

This machine needs only one man to take the finished products on the machine. This will save a lot of labors cost especially when the labor cost gets more and more expensive. Even we have an automatic material stack for this machine, please contact us if you have any requests.

Advantages Of Metal Ceiling Tiles Production Line

Advantages Of Metal Ceiling Tiles Production Line

Fully Automatic Production Line

Utilizes self-developed automatic feeding robotic arms, automatic turning, and automatic stacking systems to achieve fully automated production of metal ceiling tiles. This machine features easy operation, smooth running, high output speed, and reduces the risk of workplace injuries.

Different sizes and types of ceilings can be produced

By changing the mold, the ceiling tile production line can produce 30x30cm, 60x60cm, 60x120cm and other sizes of tiles, and can also produce a variety of types of tiles such as clip-in, lay-in, and tegular. The replacement of the mold is very convenient, saving time and the cost of buying other machines.

Cost Reduction and Safety Improvement

The fully automatic ceiling production line is controlled by sensitive mechanical actions, eliminating the need for manual precision control. This reduces labor costs and minimizes safety risks associated with manual work.

Reduction of Waste

The hydraulic press performs one-step cutting of all four corners and bending of all four edges. This process reduces waste and saves costs.

Composition Of Complete Production Line

Composition Of Complete Production Line

| Machine | Features | Amount |

| Decoiler | Hydraulic expansion | 1 Unit |

| Pre-straightener | High-precision 19 Rollers | 1 Unit |

| 125 Tons High-Speed Perforation Press | 125Tons, 100-150 SPM, 2-5PCS tiles/min | 1 Unit |

| NC Servo feeding machine | Yaskawa Servo motor, 3.0KW High accuracy | 1 Unit |

| Hydraulic notching & shearing press | 60tons Hydraulic press, High accuracy | 1 Unit |

| Transmission conveyor | Automatic | 2 Units |

| Precision straightener | High-precision 21 Rollers | 1 Unit |

| Automatic tiles flipping machine | For flipping 600*600 tiles 180 degrees | 1 Unit |

| Automatic feeding mechanical arm | For feeding 600*600 tiles to next step production | 1 Unit |

| Hydraulic bending forming press | For bending forming 600*600 tiles | 1 Unit |

| Electric control system | Reliable parts | 1 Unit |

One Machine Can Produce Different Product

One Machine Can Produce Different Product

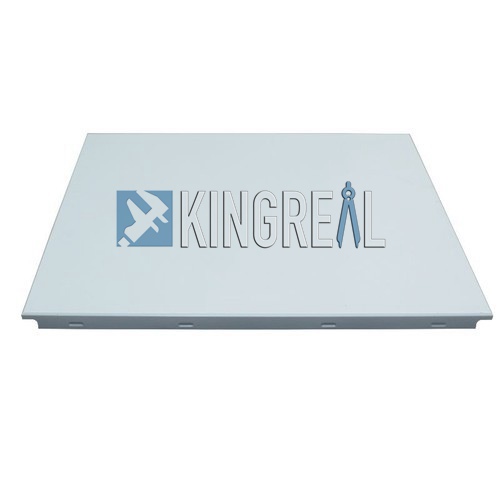

1. Plain ceiling tile:

Our 300mm aluminum ceiling tiles do not need the perforation so it is a different structure from the 600mm aluminum ceiling tiles.

After flattening, the material will go to the punch machine directly to do the corner punch, technical punch and the final forming process. The whole production would be high quality.

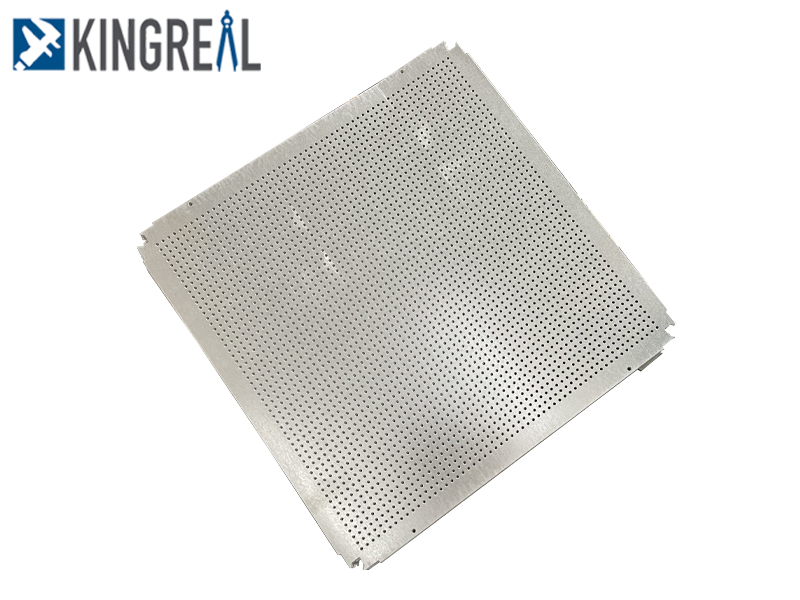

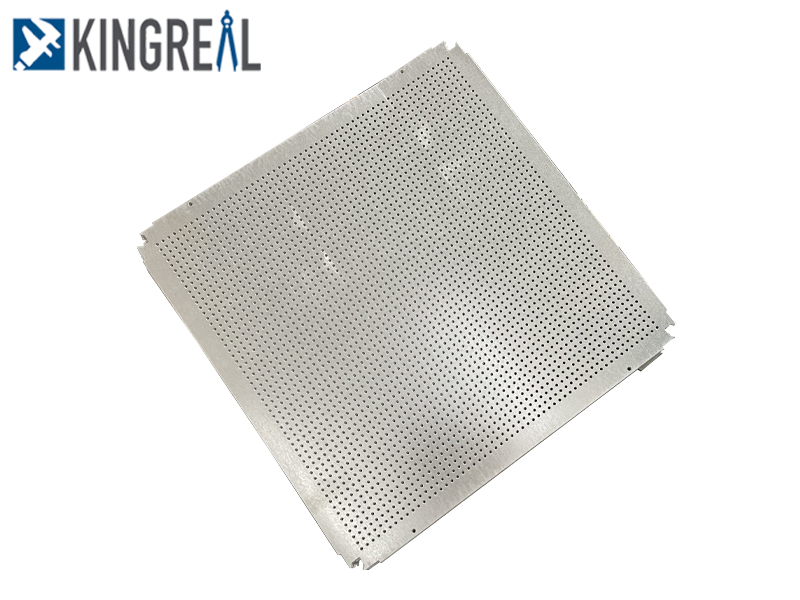

2. Perforated ceiling tile:

We can also produce 300mm*300mm perforated integrated ceiling tiles on this machine. And 300*300mm perforated ceiling tiles is very popular in Turkey. We had successfully designed and manufacture the full automatic 300*300mm perforated aluminum ceiling tiles for our Turkey Customer.

Working Process

Working Process

FAQ

FAQ

1. How do manufacturers respond to new changes in the ceiling?

The first generation products are gypsum board and mineral wool board; the second generation products are PVC; the third generation products are metal ceilings.

2. The origin and development of the metal ceiling

Metal ceilings play an extremely important role in home decoration. The ceiling decoration also plays the role of covering beams, columns, pipelines, heat insulation and sound insulation.

After-Sales Services

After-Sales Services

Services are always highly considered by us, in addition to establishing a complete remote service system, localized after-sales service is also what we have been insisting on doing. The global localization service point is under construction.

KINGREAL in Diverse Exhibition

KINGREAL in Diverse Exhibition

|

1. Plain ceiling tile: After flattening, the material will go to the punch machine directly to do the corner punch, technical punch and the final forming process. The whole production would be high quality. |

|

|

2. Perforated ceiling tile: We can also produce 300mm*300mm perforated integrated ceiling tiles on this machine. And 300*300mm perforated ceiling tiles is very popular in Turkey. We had successfully designed and manufacture the full automatic 300*300mm perforated aluminum ceiling tiles for our Turkey Customer. |

Working Process

Working Process

FAQ

FAQ

1. How do manufacturers respond to new changes in the ceiling?

The first generation products are gypsum board and mineral wool board; the second generation products are PVC; the third generation products are metal ceilings.

2. The origin and development of the metal ceiling

Metal ceilings play an extremely important role in home decoration. The ceiling decoration also plays the role of covering beams, columns, pipelines, heat insulation and sound insulation.

After-Sales Services

After-Sales ServicesServices are always highly considered by us, in addition to establishing a complete remote service system, localized after-sales service is also what we have been insisting on doing. The global localization service point is under construction.

KINGREAL in Diverse Exhibition

KINGREAL in Diverse Exhibition