How to choose a baffle ceiling machine?

2025-04-11 17:00

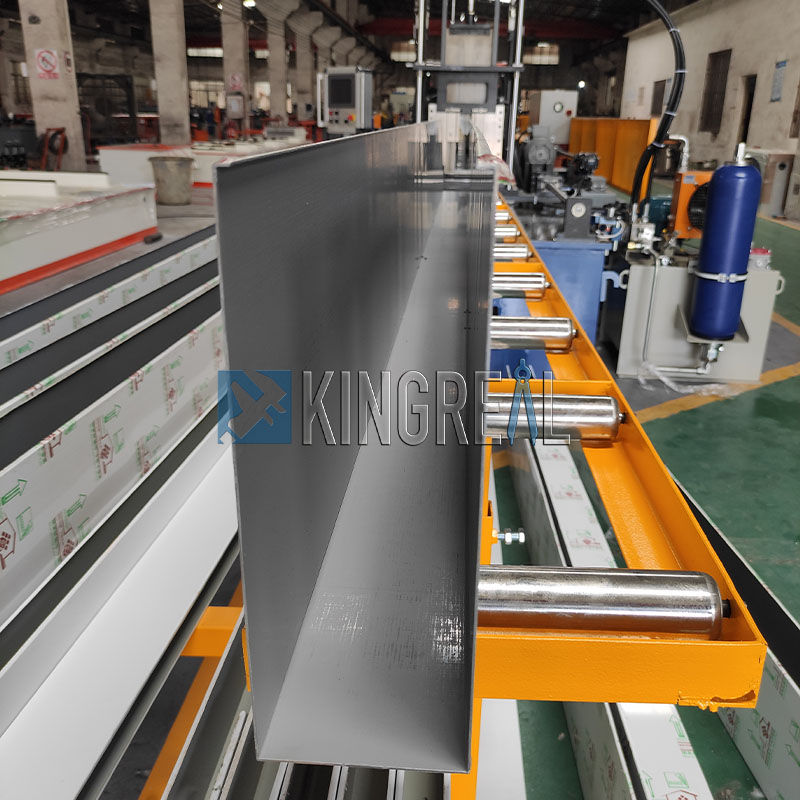

Definition of Baffle Ceiling Machine

Baffle ceiling machine is a kind of equipment specially used to process metal coils into baffle ceilings of different sizes and shapes. Through the cooperation of precision parts such as decoiler, precision leveling machine, and main roll forming machine, baffle ceiling making machine can efficiently produce various baffle ceilings, among which U-shaped and V-shaped baffle ceilings are common. These baffle ceilings are widely used in the decoration and construction industries. Because of their beautiful, practical and durable characteristics, they have become an indispensable part of modern architectural design.

The workflow of u baffle machine usually includes the following steps: First, the metal coil is unwound by the decoiler, and then the surface of the coil is flattened by the precision leveling machine, and then it is processed into the required baffle ceiling shape by the roll forming machine. Finally, the finished product is cut into a predetermined length and prepared for subsequent installation or sale.

Importance of Suitable Baffle Ceiling Machine

Choosing the right u baffle machine is crucial to the efficiency and product quality of manufacturers. Suitable baffle ceiling making machine can not only improve production efficiency, but also reduce production costs and ensure that the quality of the final product meets customer needs. On the contrary, using an inappropriate or inconvenient baffle ceiling machine will have a negative impact on production and even cause production stagnation.

(1) Matching machine parameters with production requirements

Inappropriate u baffle machines are often reflected in the mismatch between machine parameters and actual customer production needs. For example, if a customer needs to produce baffle ceilings of a specific thickness or width, and the selected u baffle machine cannot meet these requirements, the final product produced will not meet the customer's standards. This not only affects the market competitiveness of the product, but may also cause economic losses to customers.

(2) Product quality and customer satisfaction

The production quality of the u baffle machine directly affects the quality of the finished product. If the u baffle machine quality is not good and frequent failures occur, downtime during the production process will lead to a waste of working hours, which in turn affects the overall benefits of the company. Customers' strict requirements for product quality require manufacturers to ensure the stability and reliability of the selected u baffle machine.

(3) Convenience of repair and maintenance

Maintenance and maintenance of the baffle ceiling machine are also important factors affecting production efficiency. If a baffle ceiling making machine needs frequent repairs, it will inevitably delay production progress and increase labor and time costs. Therefore, choosing an easy-to-maintain u baffle machine can save manufacturers valuable production time and improve overall production efficiency.

Precautions for Choosing U Baffle Machines

When selecting baffle ceiling making machines, manufacturers need to consider many factors to ensure that the selected u baffle machine can meet their own production needs.

(1) Select according to actual conditions

The first step in choosing a baffle ceiling making machine is to evaluate it according to your actual conditions. KINGREAL CEILING MACHINERY engineers will carefully ask customers about metal materials, thickness, production speed and other aspects, and then provide customized solutions for them. KINGREAL CEILING MACHINERY u baffle machines have three models: 150mm height baffle ceiling machine, 200mm height baffle ceiling making machine and 300mm height baffle ceiling machine, which can produce 150mm, 200mm and 300mm height baffle ceilings respectively. Clarifying production specifications is the key to ensuring accurate selection. Moreover, KINGREAL CEILING MACHINERY can also add parts to the baffle ceiling machine according to the special needs of customers, such as adding a protective shield to the baffle ceiling making machine to ensure the production safety of workers, or equipping the decoiler with a feeding trolley to achieve a more efficient and automatic baffle ceiling production process.

(2) Choose a reliable manufacturer

It is very important to choose a reputable manufacturer. As a manufacturer with more than 20 years of experience, KINGREAL CEILING MACHINERY has established a set of standardized production processes and service systems. By choosing such a manufacturer, customers can not only obtain high-quality baffle ceiling making machine, but also enjoy professional after-sales service.

(3) Pay attention to after-sales service

Purchasing a u baffle machine is not the end of the transaction, and subsequent repairs and maintenance are equally important. Therefore, when choosing a supplier, it is very important to understand its after-sales service system. KINGREAL CEILING MACHINERY will provide customers with a series of services, including accompanying factory visits, customized solutions, machine manufacturing, packaging and delivery after trial operation, and installation and operation training at the customer's factory, etc., to ensure that customers are smooth during use.

(4) Consider production efficiency

When choosing a baffle ceiling making machine, production efficiency is a factor that cannot be ignored. Efficient production can not only meet market demand, but also reduce production costs. Customers should pay attention to indicators such as equipment production speed, stability, and energy consumption to ensure that the selected baffle ceiling machine can maintain high efficiency in long-term use.

(5) Evaluate technical support

With the advancement of Industry 4.0, intelligent equipment is increasingly valued. Whether the selected baffle ceiling making machine has intelligent control systems, data monitoring functions, etc. will directly affect the flexibility and efficiency of production. Understanding whether the manufacturer can provide relevant technical support can help customers better cope with market changes in future production.

(6) Refer to user feedback and cases

Before choosing a baffle ceiling machine, it is recommended to refer to the feedback and successful cases of existing users. KINGREAL CEILING MACHINERY has worked closely with customers in India, Italy, Saudi Arabia, Mexico, Turkey, Russia, the Netherlands and other countries, so it has a wealth of cases. These real usage experiences can provide customers with valuable references to help them better understand the performance and reliability of the u baffle machine.

Choosing a suitable u baffle machine is a process that requires comprehensive consideration, involving the performance of the baffle ceiling making machine, the reputation of the manufacturer, after-sales service, and production efficiency. It is hoped that through detailed demand analysis and professional selection guidance, manufacturers can find the most suitable baffle ceiling machine for themselves, so as to achieve efficient production and improve product quality.

If you are interested in KINGREAL CEILING MACHINERY u baffle machine, please come to consult!

Get the latest price? We'll respond as soon as possible(within 12 hours)