How to Choose a HVAC Spiral Duct Making Machine?

2025-04-09 17:00

In modern buildings and heating, ventilation and air conditioning (HVAC) systems, HVAC Spiral Duct Making Machines play a vital role. Choosing the right HVAC Spiral Duct Forming Machine not only affects production efficiency, but also the quality and applicability of the final product. In this article, KINGREAL CEILING MACHINERY will discuss in detail the definition, types, scope of use, and important considerations when choosing HVAC Spiral Duct Machines to help you make an informed decision.

1. Introduction to HVAC Spiral Duct Machines

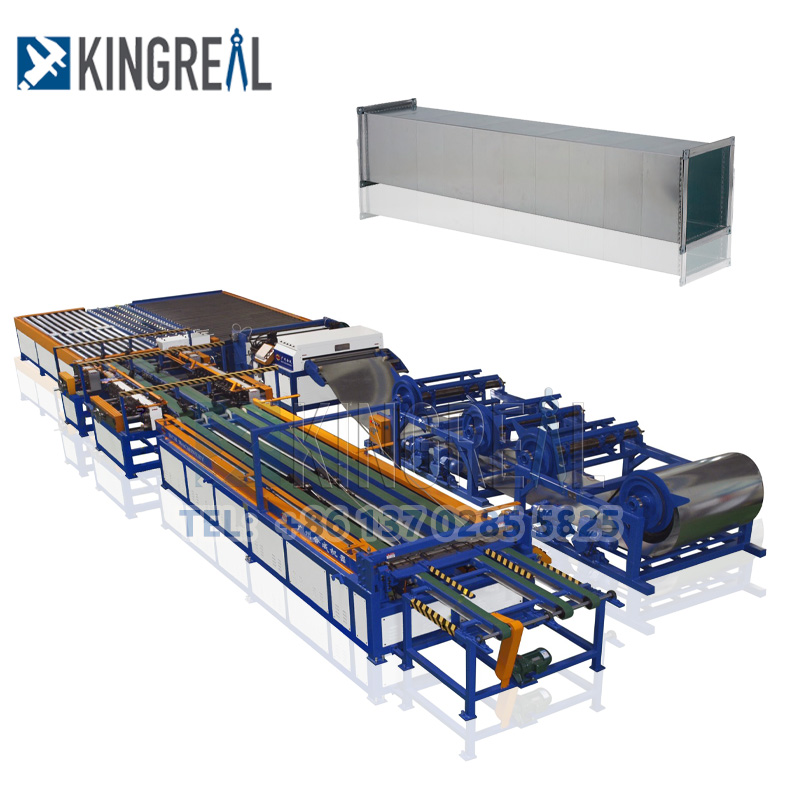

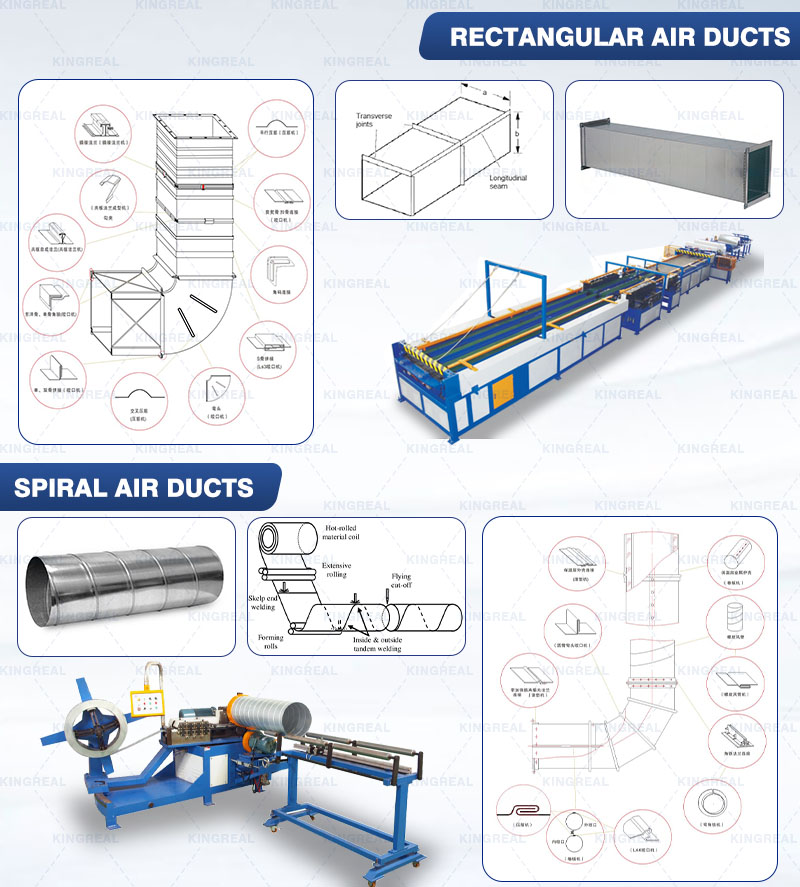

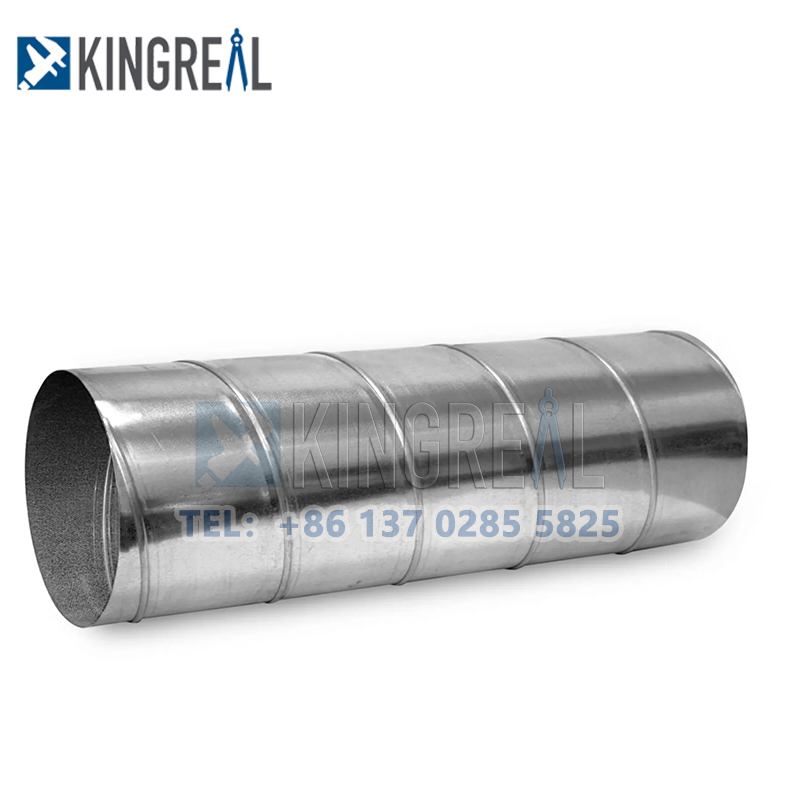

HVAC Spiral Duct Forming Machines are a type of equipment specifically used to produce ducts of various shapes and sizes. It can manufacture round spiral ducts, rectangle spiral ducts, and other special-shaped pipes, and is widely used in building materials, including aluminum pipes, steel pipes, and PVC pipes. KINGREAL CEILING MACHINERY HVAC Spiral Duct Forming Machines have many advantages and can produce ducts with low air supply resistance, high strength, and good sealing performance.

1.1 Main Features of HVAC Spiral Duct Machines

- High efficiency: KINGREAL CEILING MACHINERY HVAC Spiral Duct Forming Machines can quickly process and convert various pipe diameters, significantly improving production efficiency.

- Stability: Its design ensures the quality and consistency of the spiral duct during the production process.

- Flexibility: The size, shape and material of the spiral duct can be adjusted according to the needs to meet the needs of different customers.

2. Types of HVAC Spiral Duct Machines

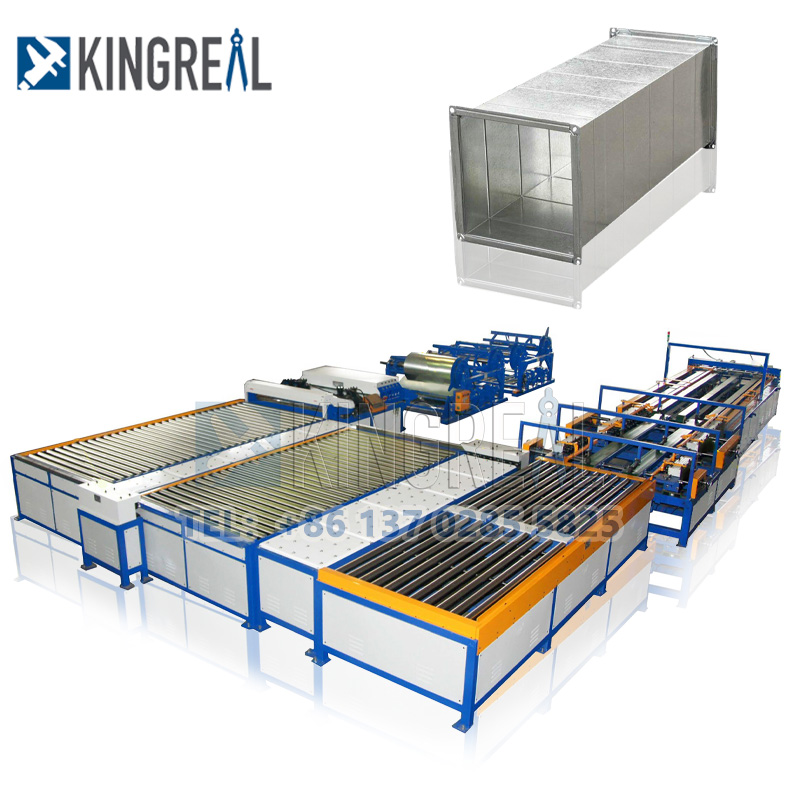

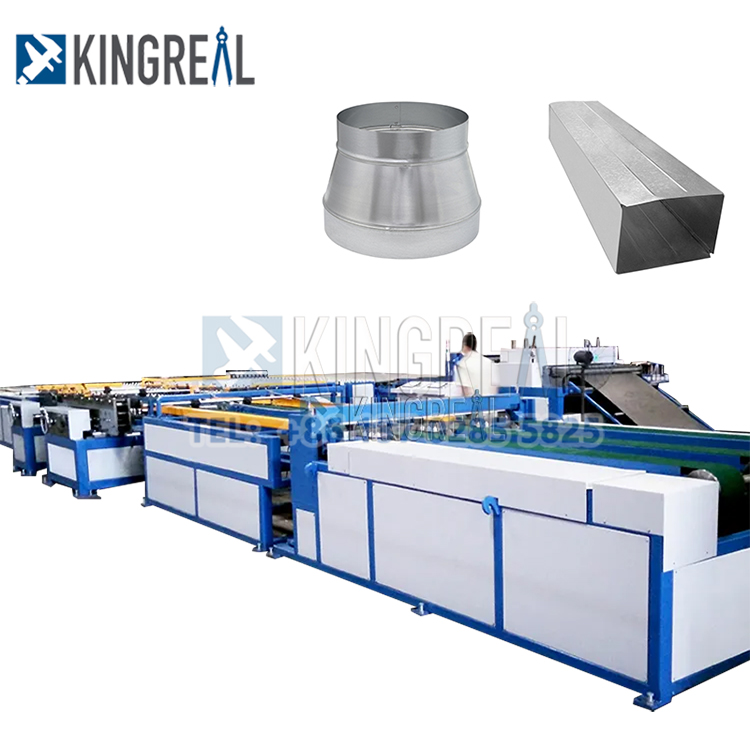

HVAC Spiral Duct Machines are mainly divided into two types: Rectangle Duct Machines and HVAC Round Spiral Duct Machines. They differ in structure, production process and application scope.

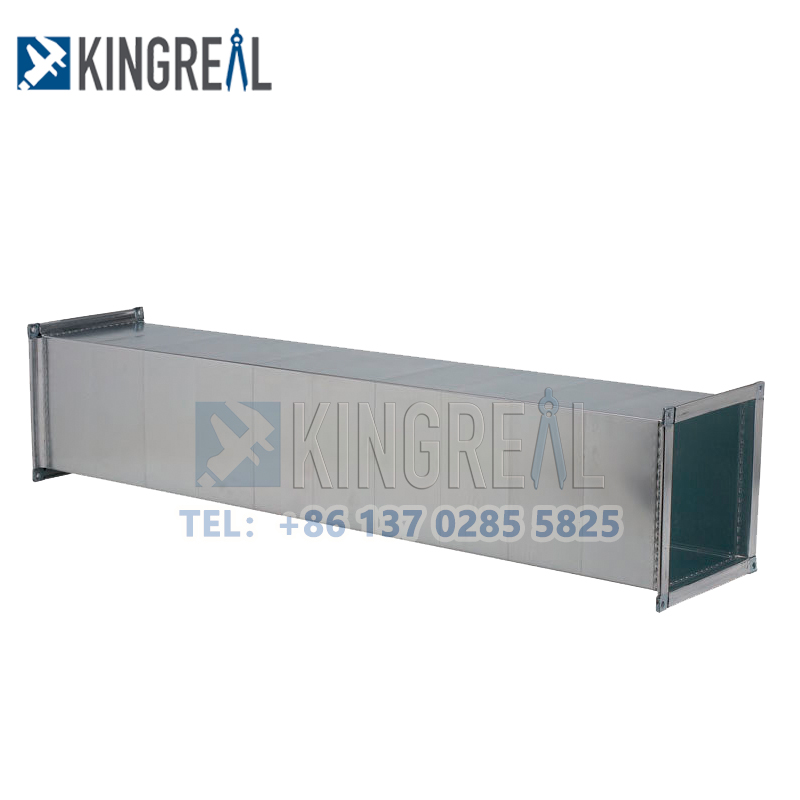

2.1 HVAC Rectangle Spiral Duct Machines

HVAC Rectangle Spiral Duct Machines are specially used to make rectangle ducts, which are usually used in applications that require space saving, such as ventilation systems in shopping malls, office buildings and residences.

★ Application scope

- Commercial buildings: In large commercial buildings, rectangle ducts can effectively distribute air and adapt to complex building structures.

- Residential: In home heating and air conditioning systems, rectangle ducts are often used as main or branch pipes.

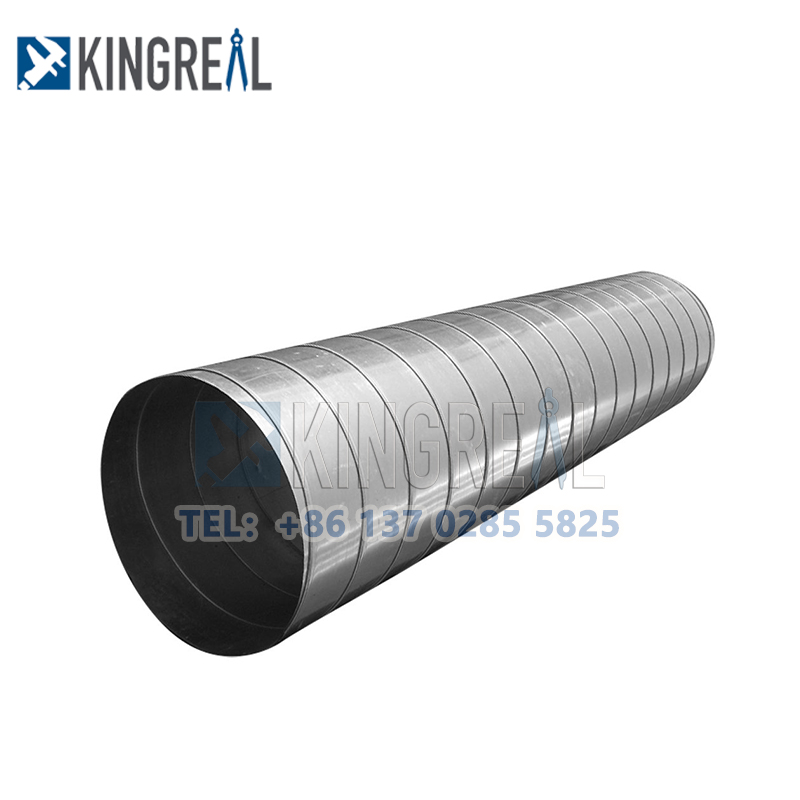

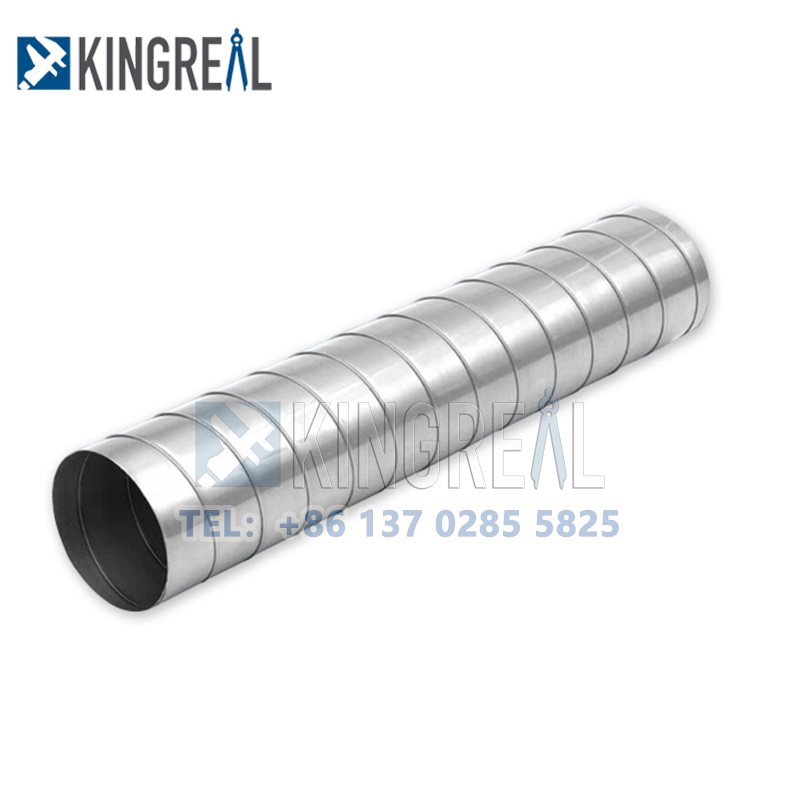

2.2 HVAC Round Spiral Duct Machines

HVAC Round Spiral Duct Machines are used to produce round spiral ducts, which are commonly found in HVAC systems in industrial and commercial buildings.

★ Application Scope

- Industrial facilities: Round ducts are widely used in industrial environments because their round structure can effectively withstand airflow pressure.

- Large buildings: In the ventilation and exhaust systems of large buildings, round ducts are widely used due to their excellent airflow characteristics.

2.3 Comparison of Different Types

Although square ducts and round ducts are both functionally used for air delivery, they differ significantly in their application scope, airflow characteristics, and installation methods. Square ducts take up relatively less space, but may not be as efficient as round ducts in terms of airflow pressure loss. Therefore, choosing the right type of spiral duct needs to be determined based on specific application requirements and space constraints.

3. Considerations for Choosing a HVAC Spiral Duct Forming Machine

When choosing a HVAC Spiral Duct Machine, there are several important considerations to pay attention to to ensure that the selected equipment can meet production needs.

3.1 Clarify Your Needs

First, you need to clarify your needs, including whether you need to manufacture round or square ducts. Depending on the nature of the project, choosing the right HVAC Spiral Duct Forming Machine will directly affect production efficiency and product quality.

3.2 Choose a Reliable Manufacturer

Choosing a trustworthy manufacturer is crucial. KINGREAL CEILING MACHINERY has its own factory, and you can come to the factory to visit and test the HVAC Spiral Duct Machine in person to ensure that it can meet your needs. Good communication with the manufacturer will help you get professional advice and technical support.

3.3 Customized Solutions

Working with engineers to set up a HVAC Spiral Duct Forming Machine manufacturing solution that meets your needs is key. KINGREAL CEILING MACHINERY engineers will dig deep into the specific needs of customers, including:

- Processed metal materials: Different materials have different requirements for HVAC Spiral Duct Machines.

- Metal thickness: Different thickness materials require different processing technologies.

- Running speed: Choose the appropriate running speed according to production needs.

- Duct size: Make sure the HVAC Spiral Duct Forming Machine can meet the required duct size.

3.4 Technical Parameters of HVAC Spiral Duct Making Machines

When choosing a HVAC Spiral Duct Forming Machine, you also need to carefully evaluate the technical parameters of the equipment, including:

- Production capacity: The number of spiral ducts that can be produced per hour.

- Power consumption: The energy efficiency of the HVAC Spiral Duct Machine, which directly affects the production cost.

- Operation interface: Is it easy to operate and maintain, and reduce labor costs.

3.5 Customer Reviews and Feedback

It is also very important to check other customers' reviews and feedback before making a final decision. This can help you understand the performance, durability and after-sales service quality of the HVAC Spiral Duct Forming Machine.

3.6 After-sales Service and Support

Choosing a manufacturer that provides good after-sales service will save you a lot of worries. Make sure the manufacturer can provide timely technical support and parts replacement services to avoid problems that cannot be solved in time during the production process.

4. Main Markets of HVAC Spiral Duct Machines

HVAC Spiral Duct Forming Machines play an important role in modern construction and air conditioning industries, especially in the following countries and regions. The market demand in these regions is mainly affected by multiple factors such as industrialization, construction industry development, and the demand for efficient ventilation systems.

4.1 United States

The United States is one of the largest HVAC markets in the world, and the demand for HVAC Spiral Duct Forming Machines mainly comes from the following aspects:

- Old building renovation: Many old buildings need to upgrade their ventilation systems to improve energy efficiency and comfort. HVAC Spiral Duct Forming Machines play a key role in this process.

- High standard building codes: The United States has strict regulations on ventilation and air quality in buildings, which drives the demand for high-quality ducts.

4.2 Germany

Germany is known for its precision manufacturing and high quality standards. The demand for HVAC Spiral Duct Machines in the country is mainly reflected in:

- Strong industrial manufacturing: Germany has a strong industrial base, and many factories need efficient ventilation systems to maintain the suitability of the production environment.

- Green building advocacy: Germany is at the forefront of green building and sustainable development, which promotes the demand for high-efficiency air ducts.

4.3 Japan

Japan is a technologically advanced country, and the demand for HVAC Spiral Duct Forming Machines here is mainly affected by the following factors:

- High-density urbanization: In the process of urbanization, the design and layout of ventilation systems are particularly important when space is limited, and the application of circular air ducts is becoming more and more widespread.

- Earthquake safety standards: Buildings in Japan must meet strict safety standards, and the design and material selection of air ducts are crucial to the safety of buildings.

4.4 India

With the rapid development of India's economy, the construction industry and HVAC market are also growing rapidly, and the demand for HVAC Spiral Duct Making Machines is rising. The main reasons include:

- Increased investment in infrastructure construction: The government's investment in infrastructure has promoted the rapid development of the construction industry and promoted the demand for HVAC systems and HVAC Spiral Duct Machines.

- Accelerated urbanization: The increase in urban population and the development of emerging cities have led to a rising demand for ventilation systems.

4.5 Brazil

As the largest economy in South America, Brazil's demand for ducted air conditioners is mainly driven by the following factors:

- Huge market potential: Brazil's construction market is developing rapidly, especially in the commercial and residential sectors.

- International large-scale events: International events such as the 2014 World Cup and the 2016 Olympic Games have driven the construction of infrastructure and the demand for HVAC systems.

Get the latest price? We'll respond as soon as possible(within 12 hours)