What is the common metal ceiling machine type?

2025-04-07 17:00

In the modern construction and interior decoration industry, metal ceilings are not only structures that cover the top of the house, their design and materials also have an important impact on the beauty, functionality and acoustic performance of the room. As the market's requirements for ceiling quality and functionality continue to increase, the production methods of ceilings are also evolving. There are various types of metal ceiling machines, the most common of which is the fully automatic metal ceiling panel production line. The fully automatic aluminum ceiling tile machine has become the first choice of many manufacturers due to its high efficiency and flexibility.

Introduction to Fully Automatic Metal Ceiling Machine

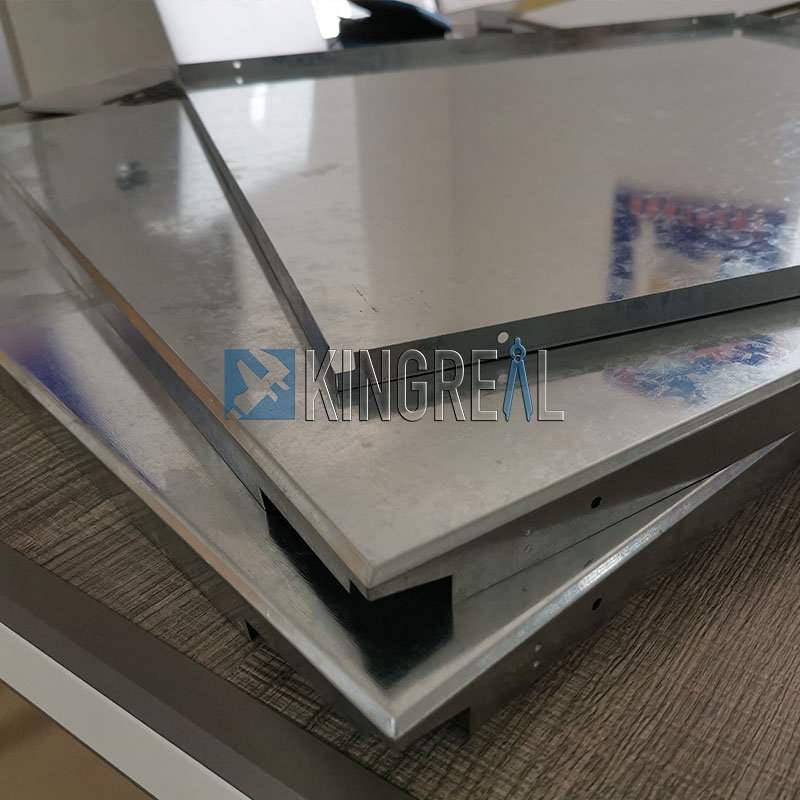

The fully automatic aluminum ceiling tile machine is an integrated production system that can realize a fully automated production process from raw materials to finished products. This metal ceiling panel production line has a variety of configurations and can produce ceilings of different sizes (such as 300x300mm, 600x600mm, 600x1200mm, etc.) and different types (such as clip in, lay in, tegular, etc.) to meet the diverse needs of the market.

1. Diversity of production sizes

KINGREAL CEILING MACHINERY fully automatic aluminum ceiling tile machine can produce ceilings of various sizes, such as 300x300mm, 600x600mm, 600x1200mm, etc. Among them, 300x300mm ceilings are suitable for home decoration, while 600x1200mm ceilings are more suitable for commercial spaces. Therefore, manufacturers can choose the appropriate KINGREAL CEILING MACHINERY aluminum ceiling tile machine according to their own production needs for ceiling sizes.

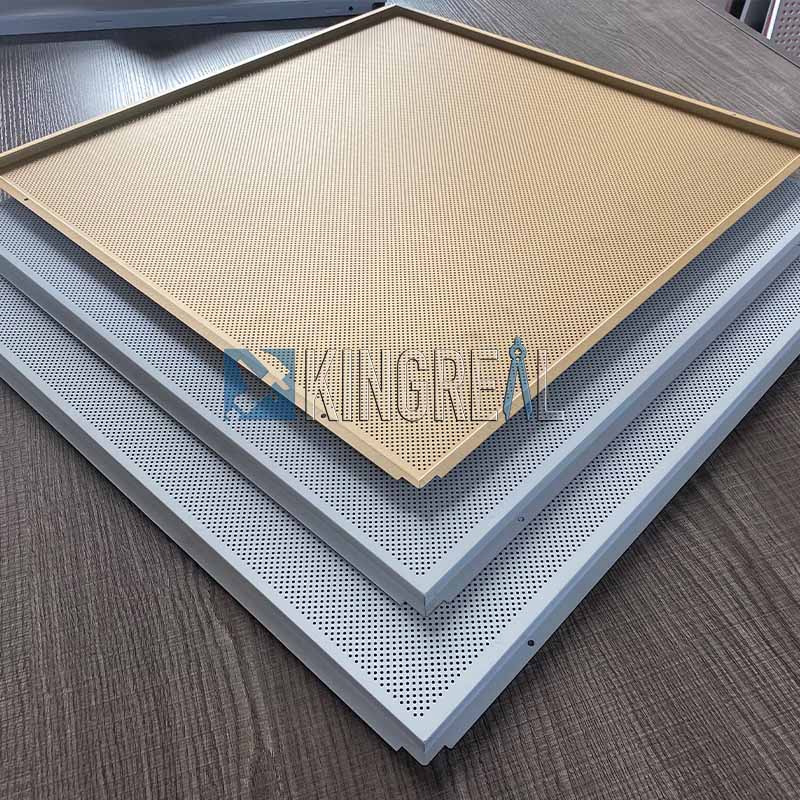

2. Diversity of production types

KINGREAL CEILING MACHINERY fully automatic metal ceiling panel production line can also produce various types of ceilings, such as clip in, lay in, tegular, etc. These different types of ceilings have their own characteristics in installation methods, appearance effects and functions, meeting the needs of different customers. For example, clip in ceilings are easy to disassemble and replace, suitable for places that require frequent maintenance; while lay in ceilings have a good balance between aesthetics and practicality.

3. Equipped with multifunctional equipment

In order to meet the personalized needs of customers, manufacturers such as KINGREAL CEILING MACHINERY can equip the fully automatic aluminum ceiling tile machine with a variety of auxiliary equipment to achieve a more efficient production process.

On the fully automatic aluminum ceiling tile machine, the configuration of various equipment is the key to achieving efficient production. Among them, the four major equipment of feeding trolley, metal sheet cleaning machine, acoustic fleece sticking machine and metal ceiling tile perforation machine constitute an important part of the production process, ensuring production efficiency, product quality and customer satisfaction. The functions and advantages of these four equipment will be discussed in detail below.

1. Feeding trolley The feeding trolley is an indispensable part of the fully automatic metal ceiling panel production line. Its main function is to accurately transport metal coils from the storage location to the decoiler. Although this process seems simple, its importance cannot be underestimated. Traditional ceiling production methods often require workers to manually carry metal coils, which is not only time-consuming and labor-intensive, but may also cause personal injury or material damage. After using the feeding trolley, the operator only needs to set the program, and the feeding trolley can automatically complete the handling work, greatly saving labor costs. Through this automated system, companies can reallocate human resources to higher-value work, thereby improving overall work efficiency. The introduction of the feeder trolley makes the material flow of the aluminum ceiling tile machine smoother. During the production process, the rapid delivery of metal coils reduces waiting time and improves the overall efficiency of the metal ceiling panel production line. In addition, the stability and accuracy of the feeder trolley also reduce the error rate in the material handling process, ensure the timely use of materials, and avoid the waste of raw materials caused by handling errors. |  |

| 2. Metal sheet cleaning machine

The metal sheet cleaning machine plays an equally important role in the aluminum ceiling tile machine. It is responsible for cleaning the surface of the metal ceiling after production is completed to ensure that the product meets the sales standards before leaving the factory. Metal ceilings will inevitably be contaminated with impurities such as oil and dust during the production process. These dirts not only affect the appearance of the product, but may also affect the subsequent coating or patching process. The metal sheet cleaning machine can effectively remove these dirts to ensure that each ceiling is clean and tidy when it leaves the factory. This standardized cleaning process not only ensures the quality of the product, but also enhances customers' trust in the brand. After using the metal sheet cleaning machine, manufacturers can reduce their investment in subsequent cleaning work. Traditional manual cleaning often takes a lot of time and manpower, while the efficient cleaning capacity of the metal sheet cleaning machine greatly shortens the production cycle, allowing companies to complete orders faster and improve customer satisfaction. Especially when facing urgent orders, the efficiency of the metal sheet cleaning machine is particularly important. |

3. Acoustic fleece sticking machine

With the diversification of market demand for ceiling functionality, the introduction of the acoustic fleece sticking machine has added new vitality to the metal ceiling panel production line. It is mainly used to attach sound-absorbing cloth to metal ceilings to meet customers' requirements for sound insulation. The use of the patch machine enables the ceiling to not only have basic decorative functions, but also effectively improve the sound insulation effect to meet the use needs of commercial spaces, conference rooms and other places. By completing the patch process directly on the metal ceiling panel production line, companies can provide more value-added products, thereby enhancing market competitiveness. Modern consumers are increasingly inclined to personalized and customized products. The flexible configuration of the acoustic fleece sticking machine enables the metal ceiling panel production line to quickly adjust the patch materials and specifications according to the specific needs of customers. This flexibility not only improves customer satisfaction, but also provides more possibilities for companies to expand their markets. |  |

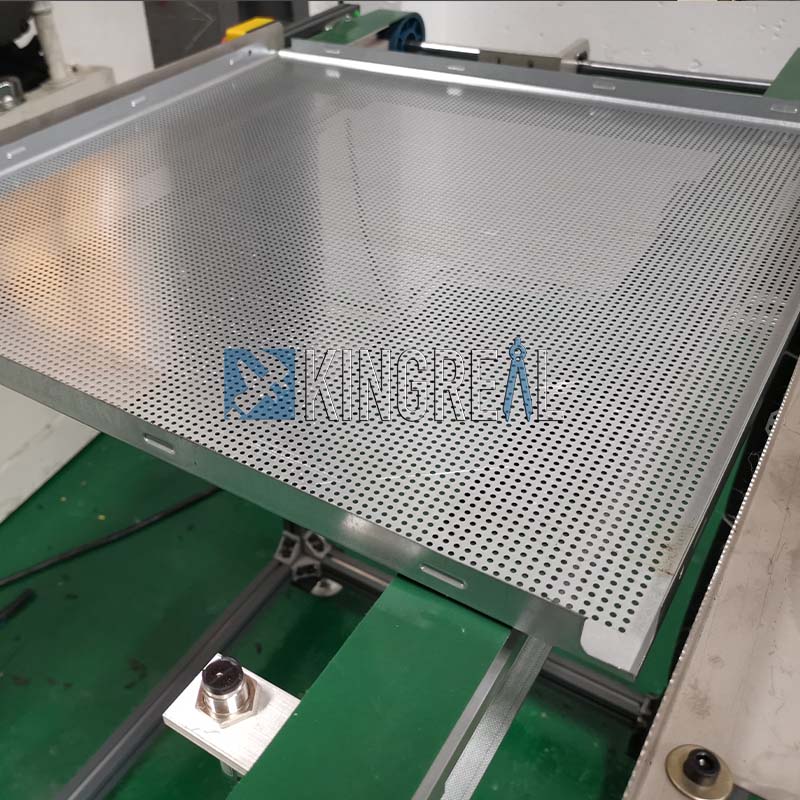

| 4. Metal ceiling tile perforation machine

The metal ceiling tile perforation machine is an important equipment for producing perforated ceilings. Its unique design makes the product have advantages in both beauty and functionality. The perforated ceiling is not only visually attractive, but its unique hole design can also effectively improve the acoustic effect of the space. This kind of ceiling is particularly popular in places such as conference rooms and theaters because it can effectively reduce echoes and noise and enhance the user's auditory experience. |

Why Do You Need a Fully Automatic Aluminum Ceiling Tile Machine?

The advantages of a fully automatic metal ceiling panel production line are not only reflected in its flexible production capacity, but also in the long-term benefits it brings. The following are several significant advantages of a fully automatic metal ceiling panel production line:

1. Save labor costs

The fully automatic metal ceiling panel production line reduces the reliance on manual operation through automation technology. Traditional ceiling production methods often require a large number of people for manual operation, and the introduction of fully automatic aluminum ceiling tile machines can significantly reduce labor costs, allowing companies to put human resources into more creative and strategic work.

2. Improve production efficiency

The fully automatic metal ceiling machine has efficient production capacity and can complete the production of a large number of products in a shorter period of time. The use of automated equipment enables each link in the production process to operate efficiently, thereby improving overall production efficiency. This efficiency is not only reflected in production speed, but also includes reducing production delays caused by human errors.

3. High return on investment

Although the initial investment of the fully automatic aluminum ceiling tile machine is relatively high, the long-term benefits it brings are obvious. By reducing labor costs, improving production efficiency and ensuring product quality, companies can achieve a return on investment in a shorter period of time. In addition, the stability and consistency of the automated aluminum ceiling tile machine also help to improve the market competitiveness of the product, thereby bringing higher sales revenue.

4. Guarantee quality

The fully automatic metal ceiling panel production line can maintain consistent quality standards during the production process. Through a precise control system, the metal ceiling machine can ensure that each ceiling meets the design requirements in terms of size, appearance and performance. This high-quality product not only improves customer satisfaction, but also establishes a good brand image for the company.

Get the latest price? We'll respond as soon as possible(within 12 hours)