Video About Linear Strip Ceiling Making Machine

Video About Linear Strip Ceiling Making Machine Description of Linear Strip Ceiling Roll Forming Machine

Description of Linear Strip Ceiling Roll Forming Machine The linear strip ceiling width can be adjusted by NC system, it can be change automatically only need the operator to input the product width, height, length. And the linear strip ceiling making machine use the AC motor (speed adjustable) to do the continously automatically cold roll forming process.

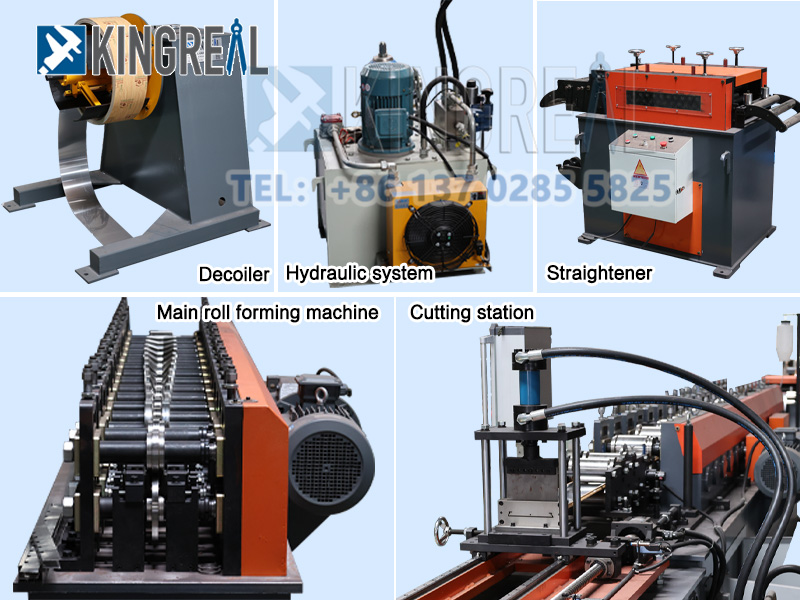

After decoiler and straightening of the raw metal coil, KINGREAL linear strip ceiling making machine can do the cold roll forming of the metal strip ceiling continously. The advantages of the KINGREAL metal strip ceiling making machine is can do different sizes of metal strip ceiling on the same machine.

Technical Specification

Technical Specification

Linear Strip Ceiling Production Line Parameters

Linear Strip Ceiling Production Line Parameters

|

Materials Materials |

Aluminum or Galvanized Steel |

|

Standard Size |

Width: 25-150mm, Height:20-250 mm |

|

Aluminum Thickness |

0.6mm- 1.2mm |

|

Length |

< 5000mm |

|

Other Tips |

wooded grain and any RAL color,we can accept your OEM designs |

Linear Strip Ceiling Product Details

Linear Strip Ceiling Product Details

|

Materials |

High quality aluminum alloy or galvanized steel. |

|

Surface finish |

Standard powder coating or Outdoor polyester powder coating |

|

Surface style |

Non-perforated. |

|

Size |

Width 40mm ;Height 150mm |

|

Edge type |

straight |

|

Total panel thickness |

Ranging from 0.50 to 1.2mm |

|

Color patterns |

Various color patterns are available as per company color pattern book |

|

Certificates |

ISO9001:2008, ISO14001:2004, CE, GB/T28001-2011, SGS. Intertek Tests. |

|

Others |

Customized order available |

|

Packing |

Standard carton box |

|

Accessories |

Special carrier available |

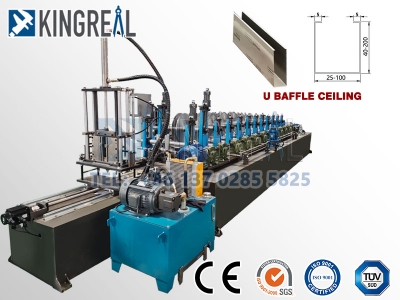

Main Components of Metal Strip Ceiling Making Machine

Main Components of Metal Strip Ceiling Making Machine

| - Decoiler - Leveler - Main roll forming machine - Shearing and bending system |

|

Features of Metal Strip Ceiling Making Machine

Features of Metal Strip Ceiling Making Machine|

Precision Straightener Machine

|

|

|

Long Service Life Machine The linear srip ceiling making machine body and rollers are made of high-hardness steel, which is strong and wear-resistant and can withstand continuous forming operations. It is featured with high precision, easy to operate and long lasting. |

|

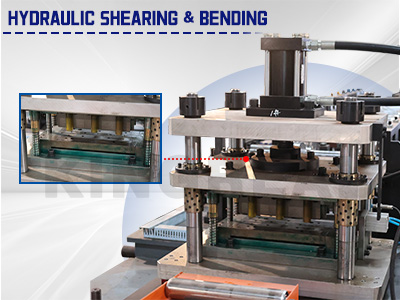

Hydraulic Shearing And Bending System KINGREAL adopts hydraulic system to driven the shearing and bending system of metal strip ceiling roll forming machine. After precision cold roll forming, the shearing and bending system will shear the linear strip ceiling to the requested length and do the bending forming accordingly. Hydraulic driven system makes the shearing and bending process more precise and faster |

|

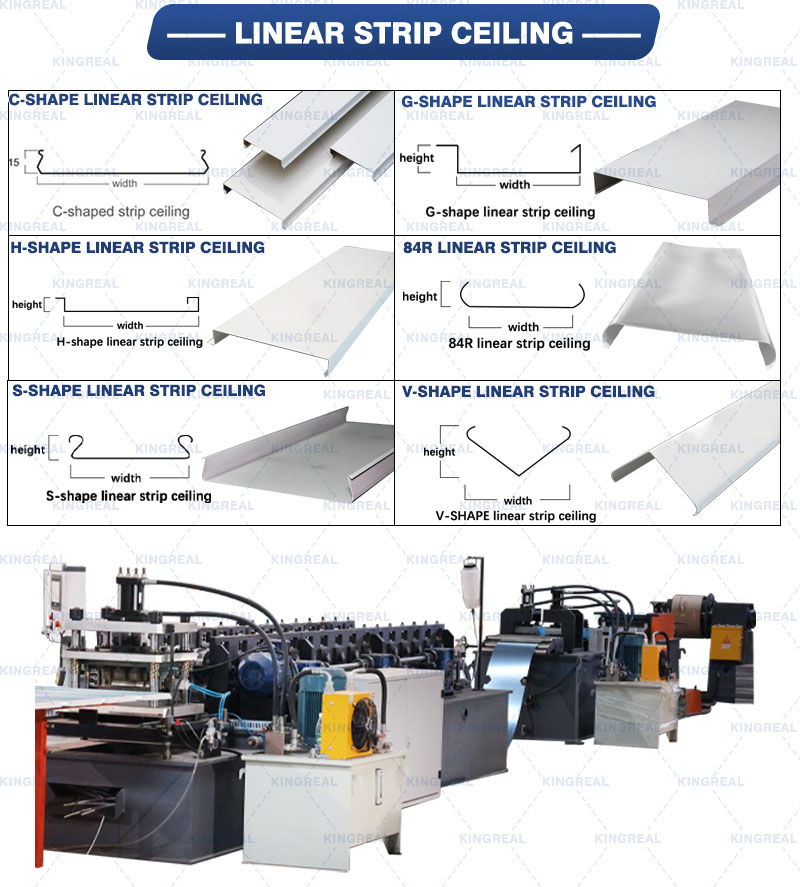

What Kinds of Linear Strip Ceiling Machine Can Provide?

What Kinds of Linear Strip Ceiling Machine Can Provide?

- C-shape linear strip ceiling roll forming machine

- G-shape linear metal ceiling roll forming machine

- H-shape strip ceiling roll forming machine

- S-shape linear strip ceiling roll forming machine

- V-shape inear metal ceiling roll forming machine

If you have other linear strip ceiling production requirement, please contact us, tell us your production needs and we will provide you with the latest machine design solutions.

Application of Metal Strip Ceiling

Application of Metal Strip Ceiling

Industrial and civil buildings, special buildings, interior partitions, suspended ceiling, wall, airport, bus station, museum, opera house, exhibition hall, shopping centre, conference hall and etc.

KINGREAL Successful Projects

KINGREAL Successful Projects

After-Sales Services

After-Sales Services

Services are always highly considered by us, in addition to establishing a complete remote service system, localized after-sales service is also what we have been insisting on doing. The global localization service point is under construction.