what's the purpose of sheet metal leveling machine?

2025-03-12 17:00

Video about

sheet metal leveling machine

Definition of sheet metal leveling machine

Sheet metal leveling machine is an important metal processing equipment, which is widely used in the processing of metal materials such as steel and aluminum. Its main function is to correct metal sheets by mechanical means to achieve ideal flatness. With the development of modern industry, the position of sheet metal leveler in the field of metal processing is becoming more and more important.

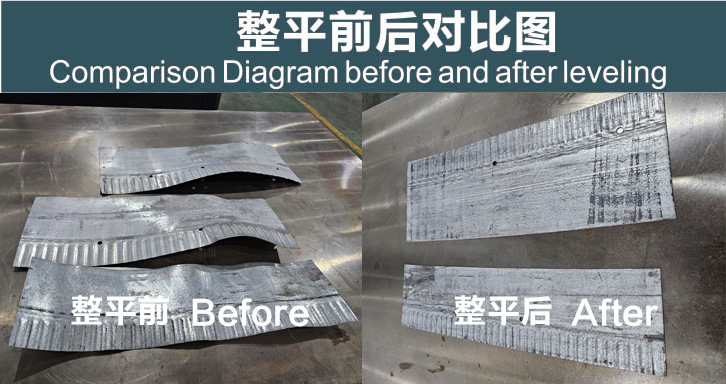

The working principle of metal sheet leveler machine is based on the elastic plastic deformation characteristics of materials. Usually, the sheet metal leveler consists of a set of upper rollers and a set of lower rollers. The gap between the upper roller and the lower roller can be adjusted as needed. When the metal sheet passes through the gap between the upper and lower rollers, the roller system applies pressure to cause the sheet to deform plastically. Through the action of mechanical force, the metal sheet can eliminate internal stress, thereby improving the flatness. This metal sheet leveler machine can effectively handle deformation caused by cooling, welding or other processing methods, and ensure the quality and precision of metal materials in subsequent processing.

Application field of sheet metal leveler

The application field of metal sheet leveler machine is very wide, covering almost all industries that require metal processing. Here are some of the main application areas:

1. Steel Industry

In the steel industry, metal sheet leveler machines are mainly used to level hot-rolled and cold-rolled steel plates. Since steel is easily deformed due to temperature changes and uneven cooling during the production process, sheet metal levelers can effectively correct these deformations to meet the requirements of subsequent processing.

2. Aerospace

The aerospace field has extremely high requirements for the flatness of metal materials. Sheet metal levelers can be used to process aluminum alloy plates and other lightweight alloys to ensure their structural stability and safety when manufacturing aircraft and other aircraft.

3. Shipbuilding

In the shipbuilding industry, metal sheet leveler machines are used to level hull structural parts to ensure the accuracy of welding and assembly. In the manufacturing process of ships, sheet metal levelers can improve the flatness of metal plates and reduce problems in subsequent processing.

4. Automobile Manufacturing

The automotive industry has equally strict requirements for metal materials. Metal sheet leveler machines can be used to process metal parts of automobile bodies to ensure their flatness during the forming and welding process, thereby improving the overall quality and safety of the vehicle.

5. Home appliance manufacturing

In home appliance manufacturing, sheet metal levelers are used to process metal materials for the outer shell and internal structural parts to ensure the appearance and functional performance of the product. The leveled metal materials can provide better surface treatment effects and enhance the market competitiveness of the products.

6. Machinery manufacturing

In the machinery manufacturing industry, sheet metal leveling machines are used to process various mechanical parts to ensure their dimensional accuracy and shape stability. This is essential for the normal operation and service life of mechanical equipment.

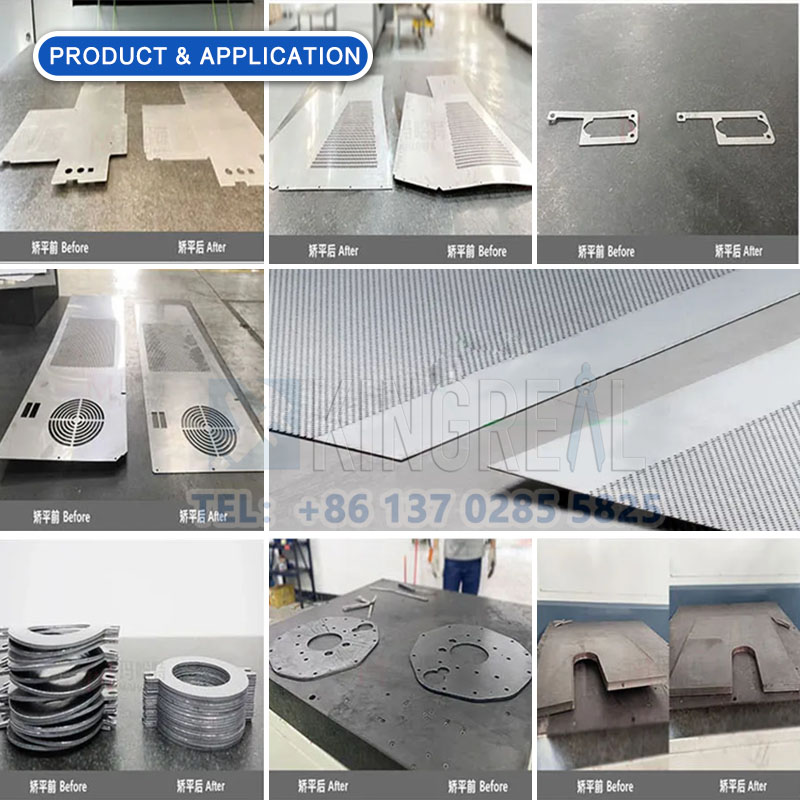

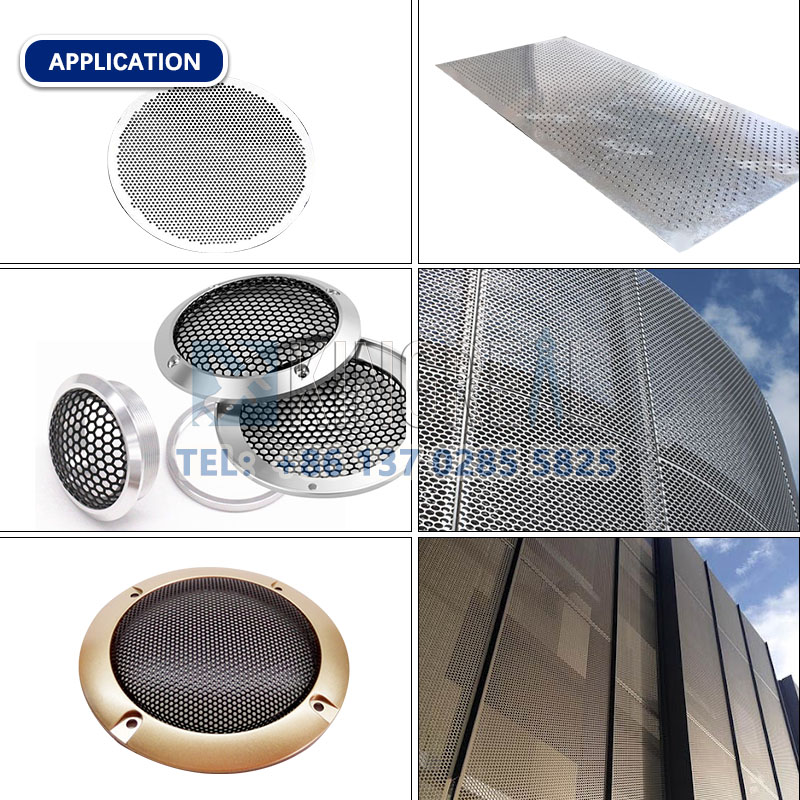

Metal sheet leveler machines can also process a variety of different metal objects, such as metal plates, metal sticks, metal parts, metal strips, metal meshes, etc. The leveled metal can be used for subsequent secondary processing and is widely used in various industries.

Market demand for sheet metal levelers

With the acceleration of global industrialization, the demand for sheet metal leveling machines in the market is also growing. Especially in some developing countries, the demand for metal sheet leveler machines is particularly obvious. For example:

1. India

India's manufacturing industry is developing rapidly. The government actively promotes the "Make in India" plan to attract foreign investment and technology, which has triggered a growth in demand for sheet metal leveling machines. Especially in the automotive and steel industries, the utilization rate of sheet metal levelers has increased significantly.

2. United States

In the United States, although the market is relatively mature, there is still a demand for high-quality sheet metal leveling machines. Especially in the fields of aerospace and high-end manufacturing, the market demand for metal sheet leveler machines is stable, which has promoted technological updates and equipment upgrades.

3. Germany

Germany is famous for its precision manufacturing, and the demand for sheet metal leveling machines in the fields of machinery manufacturing and automobile manufacturing continues to grow. German companies have high technical requirements for equipment, so high-precision sheet metal levelers are favored in the market.

The market demand in these countries and regions shows that as an important equipment for metal processing, the sheet metal leveling machine has huge market potential and good development prospects.

The use of metal sheet leveler machines

The main uses of sheet metal leveling machines are reflected in the following aspects:

1. Improving the flatness of metal materials

Sheet metal levelers can effectively eliminate the deformation of metal sheets and improve their flatness. This is especially important for subsequent processing, such as welding, cutting and forming. Flat metal materials can improve processing accuracy and reduce scrap rates.

2. Eliminate internal stress

Metal materials will generate internal stress during processing. If these stresses are not eliminated in time, they may cause the material to deform again in subsequent processing. The metal sheet leveler machine can effectively eliminate these internal stresses by applying appropriate pressure to ensure the stability of the material in subsequent processes.

3. Improve product quality

The metal materials after leveling have significant improvements in appearance and performance, which is crucial to the quality of the final product. In a highly competitive market environment, product quality is an important factor for companies to gain competitive advantages.

4. Adapt to different processing needs

The sheet metal leveler can handle a variety of different types of metal materials and adapt to different processing needs. Whether it is large-sized steel plates or small metal parts, the sheet metal leveler can provide efficient processing solutions.

5. Improve production efficiency

The application of the metal sheet leveler machine can significantly improve the efficiency of metal processing and reduce manual intervention and time costs. In modern production lines, the sheet metal leveler, as an important part of automation equipment, can work in conjunction with other equipment to improve overall production efficiency.

6. Reduce production costs

The use of metal sheet leveler machines can effectively reduce production costs by improving processing accuracy and reducing scrap rates. While ensuring product quality, companies can also increase profit margins.

Get the latest price? We'll respond as soon as possible(within 12 hours)