What's the purpose of wall cladding panel machine?

2025-03-14 17:00

As an indispensable equipment in the modern building decoration industry, the metal wall cladding panel machine has attracted widespread attention due to its efficient and precise production process. In this article, KINGREAL CEILING MACHINERY will discuss with you in detail the definition, advantages and important role of the wall cladding panel making machine in various application fields.

Definition of metal wall cladding panel machine

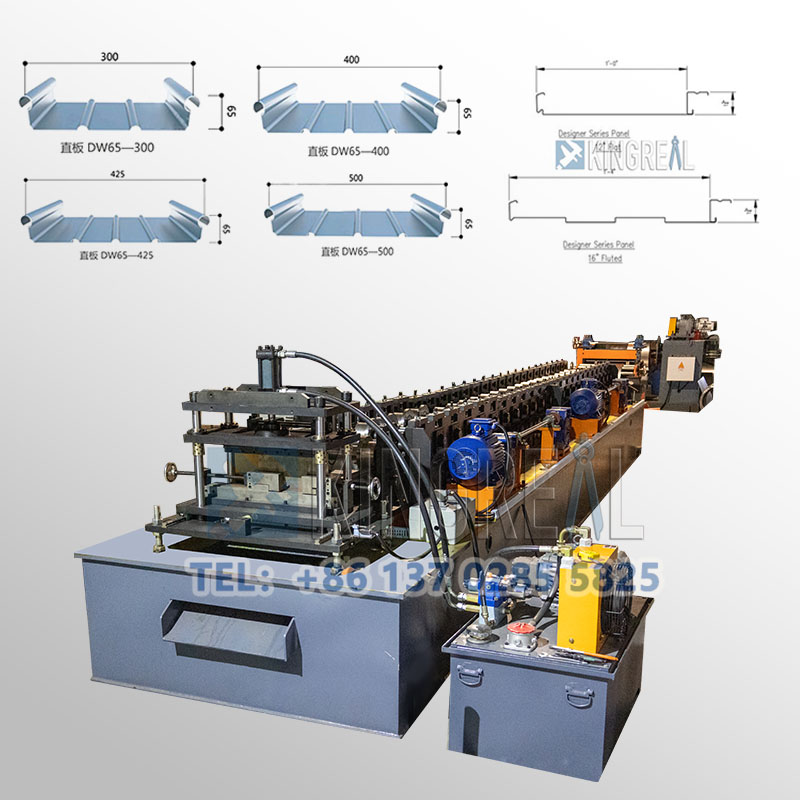

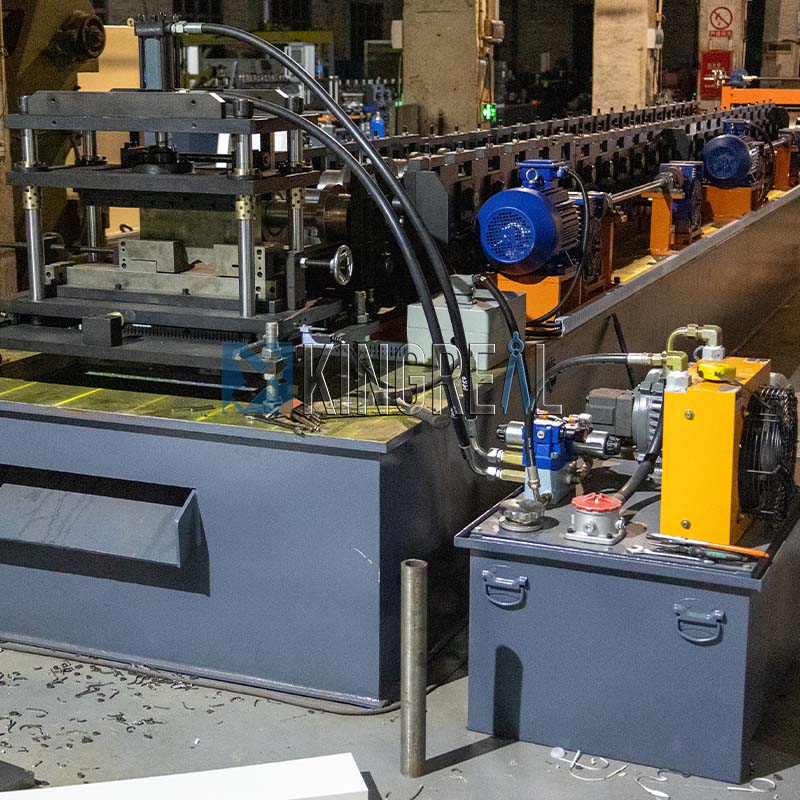

The wall cladding panel machine is a mechanical equipment specially used for the production of wall cladding panels. Through a series of efficient work processes such as unwinding, forming, and cutting, the wall cladding panel making machine can quickly and accurately produce various types of wall panels. Its fully automated design not only significantly improves production efficiency, but also ensures product consistency and quality. In addition, the flexible size adjustment function of this metal wall cladding panel machine enables it to meet the special needs of different customers and projects.

Workflow of wall cladding panel making machine

1. Unwinding: Put the metal coil into the machine, and the machine automatically unwinds the coil and prepares for forming.

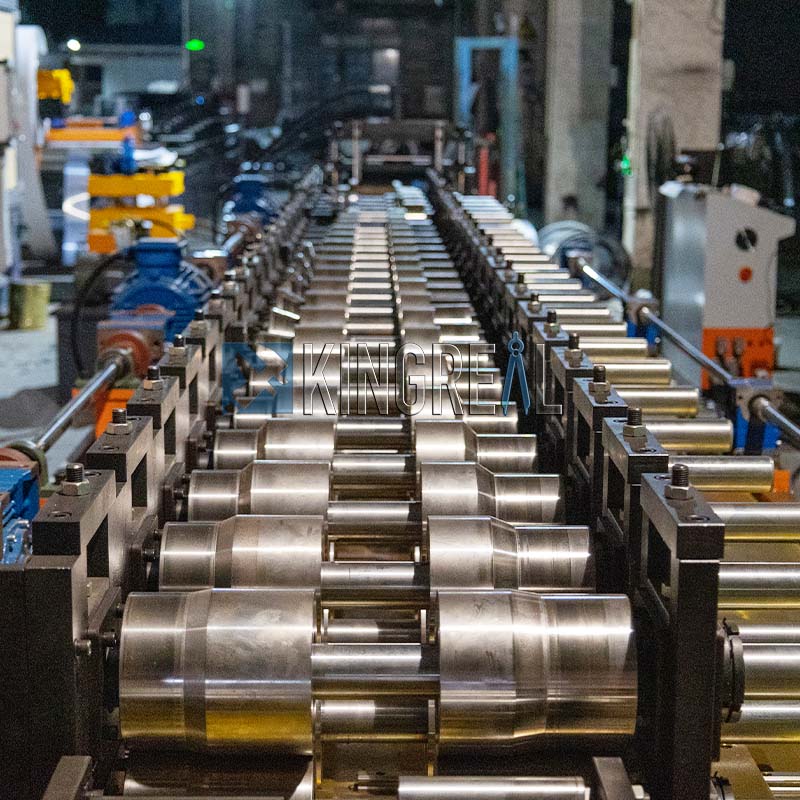

2. Forming: Through the pressing of multiple sets of forming rollers, the metal material is gradually formed to form the basic structure of the wall panel.

3. Cutting: The formed wall panels are precisely cut into the required size according to the customer's needs and design specifications.

4. Packaging: The wall panels are automatically packaged for transportation and storage.

Advantages of metal wall cladding panel machine

Wall cladding panel making machines have shown several significant advantages in the production process, making them an important position in the market.

1. Can handle metal raw materials of different materials

Metal wall cladding panel machines can handle various types of metal raw materials, including galvanized steel, aluminum alloy, stainless steel, etc. This flexibility allows manufacturers to choose the most suitable materials according to market demand and customer requirements, thereby improving the applicability and competitiveness of products.

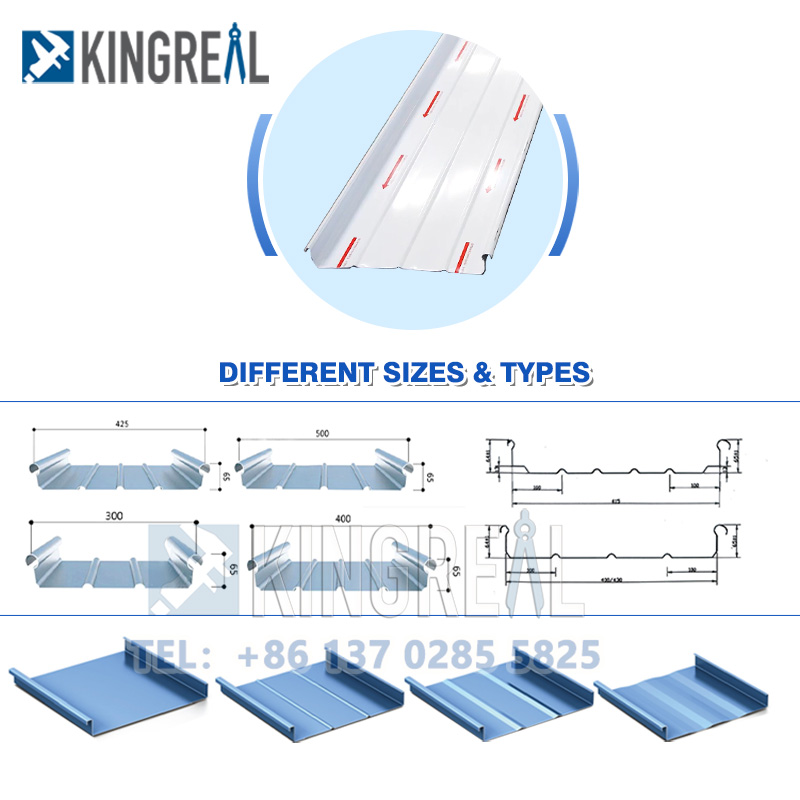

2. Can produce wall panels of different sizes

Modern wall cladding panel making machines are equipped with flexible size adjustment functions, which can quickly switch to produce wall panels of different sizes according to the needs of different projects. This feature enables manufacturers to meet the personalized needs of customers and enhance market competitiveness.

3. Fast forming speed

The efficient design of metal wall cladding panel machines makes their forming speed much higher than traditional manual production and semi-automatic equipment. The fast production process not only saves time, but also meets the needs of large-scale production and provides timely delivery to customers.

4. Full automation

The fully automated design of the wall cladding panel machine greatly reduces manual intervention in the production process, thereby reducing labor costs. At the same time, automated operation also improves production efficiency, reduces human errors, and ensures consistency in product quality.

5. Can produce different types of wall panels

The metal wall cladding panel machine is able to produce a variety of wall panels, such as partition panels, exterior wall panels, interior wall panels, etc. This diversity allows it to be widely used in various construction projects to meet the needs of different customers.

Application areas of wall panels

The wall panels produced by the wall cladding panel making machine are widely used in modern buildings and cover multiple fields. The following are some of the main application places:

1. Airports

As an important transportation hub, the airport has extremely high requirements for the beauty and safety of the internal environment. The wall panels produced by the metal wall cladding panel machine can effectively soundproof and insulate, improving the overall comfort of the airport. In addition, the modern design of the wall panels can also complement the architectural style of the airport, creating a high-end and modern atmosphere.

2. Railway Station

Railway stations are one of the main places for people to travel. Their wall panels need to have not only good sound insulation, but also wear resistance and durability. Wall panels produced by wall cladding panel making machines can effectively resist the wear and tear caused by the flow of people, ensuring that the walls of the railway station remain in good condition for a long time.

3. Office

Modern offices usually adopt an open design. The wall panels produced by wall cladding panel machines can provide good space division, which can not only ensure privacy but also maintain a sense of transparency. In addition, the diversified design of wall panels makes the office environment more beautiful and improves the work efficiency and comfort of employees.

4. Commercial buildings

In commercial buildings, wall panels need to meet functional requirements and have good visual effects. Wall panels produced by metal wall cladding panel machines can be customized with different colors and textures according to the characteristics of commercial projects to attract customers' attention and enhance brand image.

5. Hospitals

Hospitals have very strict requirements on wall materials. Wall panels need to have antibacterial and easy-to-clean properties. Professional wall panels produced by wall cladding panel making machines can meet these needs and provide patients with a safe and comfortable medical environment.

Future development of wall cladding panel machines

With the rapid development of the construction industry, the market demand for metal wall cladding panel machines is also growing. In the future, the development of wall cladding panel making machines will show the following trends:

1. Intelligence

With the advancement of Industry 4.0, metal wall cladding panel machines will increasingly adopt intelligent technology to achieve remote monitoring and operation. This transformation will further improve production efficiency and reduce management costs.

2. Use of environmentally friendly materials

As the world pays more and more attention to environmental protection, future wall cladding panel making machines will pay more attention to the use of sustainable materials. Manufacturers will develop more environmentally friendly wall panel materials to meet the market's green building requirements.

3. Personalized customization

In the future, customers' demand for personalized customization will continue to grow. Metal wall cladding panel machines will continue to improve their flexibility and adaptability to meet diverse market needs and provide more customization options.

4. Technological innovation

The advancement of science and technology will promote the continuous upgrading of metal wall cladding panel machines. In terms of production processes, equipment design and material application, manufacturers need to continue to innovate to improve product quality and production efficiency.

Get the latest price? We'll respond as soon as possible(within 12 hours)