Video Display

Video Display

What Is Gypsum Board?

What Is Gypsum Board?

Gypsum board is a building material that consists of a gypsum core board and paperboard panels. The gypsum core board is a mixture of gypsum powder, cellulose and additives that form a strong core. Paper panels are then wrapped around the sides of the gypsum core board to protect and strengthen it.

It is widely used in interior walls, ceilings, partitions, decorations and other construction fields. According to different scope of use, there are also many customers need to plaster plasterboard process requirements.

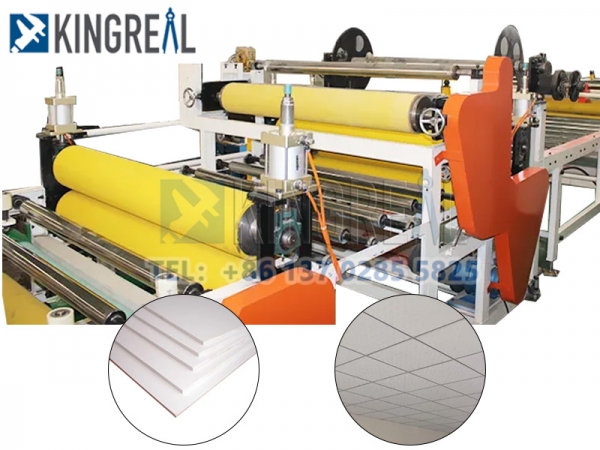

Gypsum Board PVC Laminating Machine Description

Gypsum Board PVC Laminating Machine Description

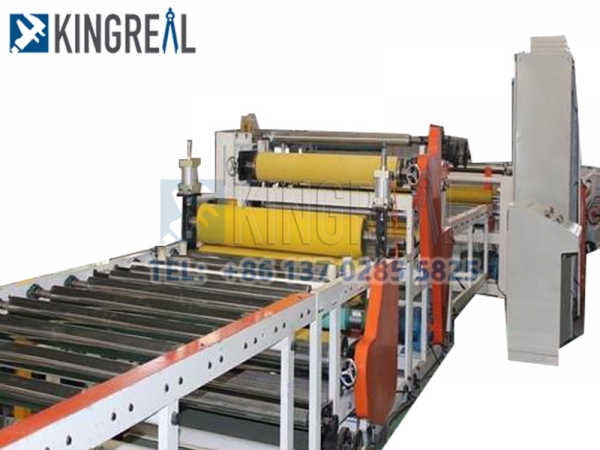

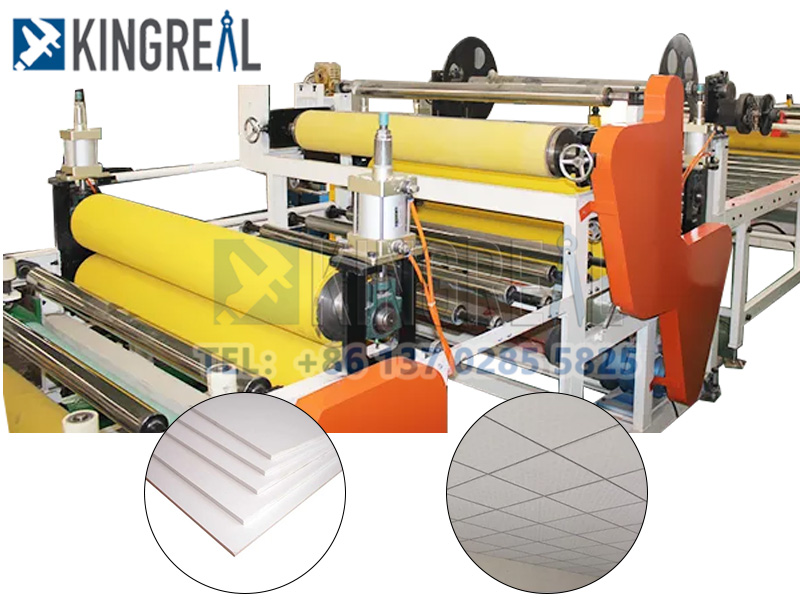

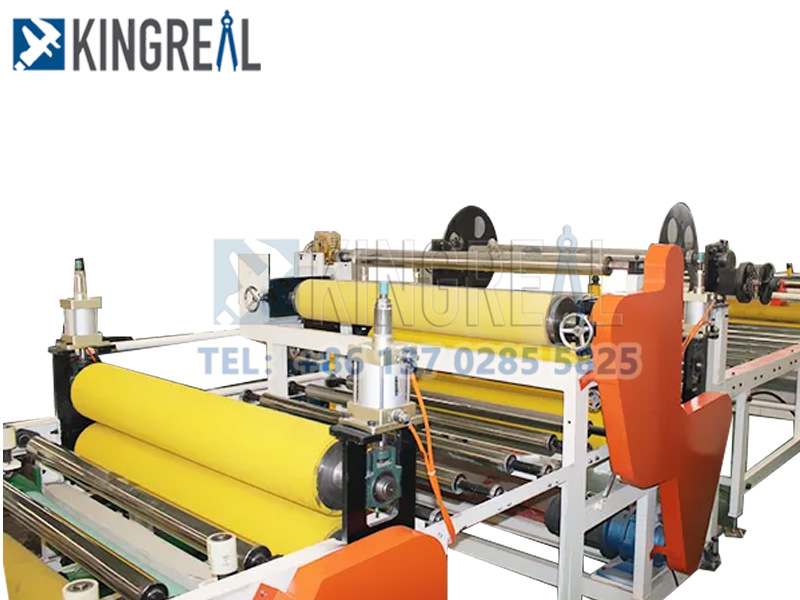

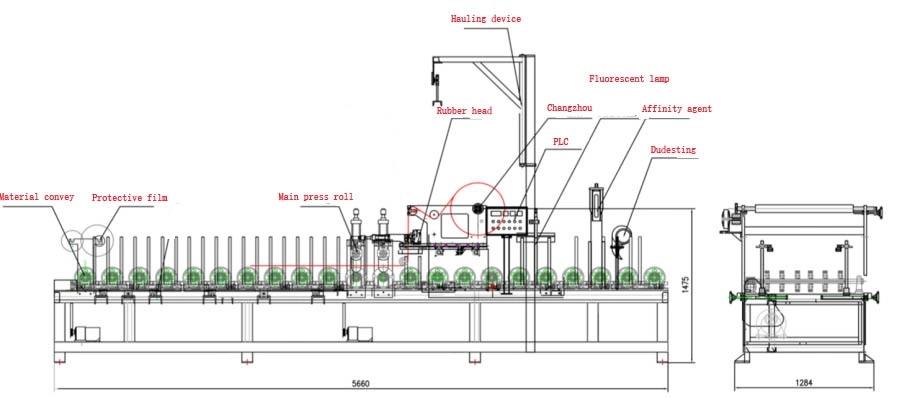

KINGREAL gypsum board laminating machine is a kind of mechanical used in the production process of gypsum board. It is mainly used to cover a layer of film(or other material) on the surface of gypsum board to improve the surface flatness and safety. The laminator usually consists of a conveying system, a film unfolding system, a laminating system and a calendering system.

Production Principle:

Production Principle:

First, the board is placed on a roller. After the dusting process, glue is applied to the board and the glue is characterized after being conveyed on the guide rollers. Then it will combine with the film and enter the reorganization mechanism.

After two rows of pressure rollers, pinch rollers and molding rollers circulating rolling, the compounding is completed. This machine is suitable for PVC skirting, profiles, profiles and other surface decorative materials such as pasting, laminating decorative film, decorative paper and so on.

Complete Production Process:

Complete Production Process:

Automatic board loading- Pre-dusting- Coating- Drying Conveyor - Aluminum Foil Unwinding - Pneumatic laminating of film to gypsum board - Cutting (manual, automatic) - Conveying - Automatic turning - Coating - Drying conveyor - PVC film unwinding - Pneumatic laminating of film to gypsum board - Slitting (manual, automatic) - Drying conveyor - Longitudinal slitting (dusting) - Horizontal slitting (dusting) - Belt machine output - Automatic lifting palletizing conveying - Edge wrapping - Stretch wrapping - Conveying - Lifting ( Finished product palletizing)

Reference Data:

Reference Data:

1. Adopting world famous brand Siemens PLC control system.

2. High capacity of 4-8 million sqm per year.

3. Raw materials: Gypsum board, PVC film, Aluminum foil, glue

4. Effective laminating width: Max 1300mm

5. Sheet thickness: 5--30mm

6. Laminating speed: Max 15m/min

7. Speed adjust way: frequency conversion synchronous speed regulating

8. Certification: ISO9001, SGS, CE, ROHS

Product Size

Product Size

L*W: 595*595mm, 600*600mm, 603*603mm, 1200*600mm

Thickness: 7.0mm, 7.5mm, 8.0mm, 8.5mm 9.0mm

The Full Lamination Line Includes The Following Machines:

The Full Lamination Line Includes The Following Machines:

1. Automatic Board Loading Machine

2. PVC Film Coating And Laminating Machine

3. Automatic Sheet Turner

4. Aluminum Foil Coating And Laminating Machine

5. Cutting Machine

6. Edge Banding Machine

7. Packing Machine

8. Palletizing Of Finished Boards

Final Product:

Final Product:

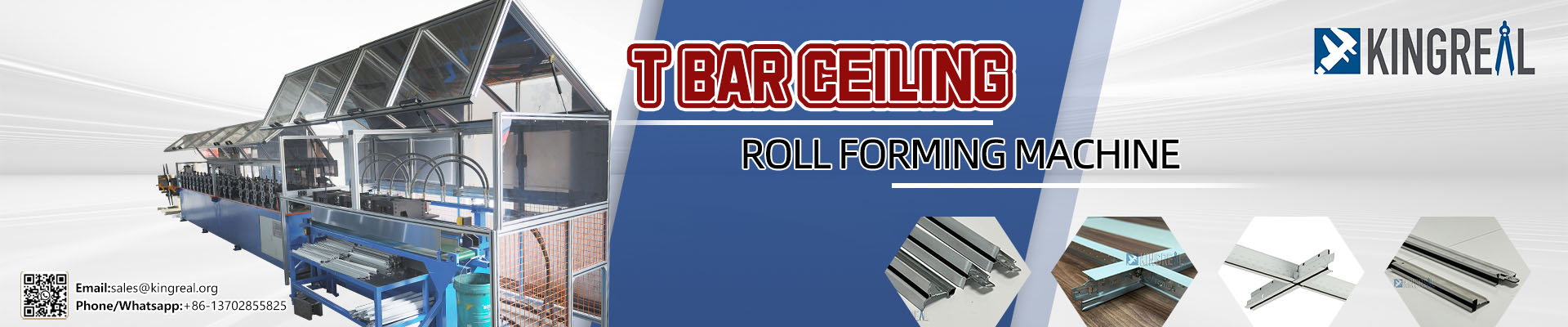

KINGREAL Other Feature Machines

KINGREAL Other Feature Machines

Years of penetration into the metalworking equipment market, KINGREAL have stocked many successful cases and localized technical support experience:

1. Metal Ceiling Tile Production Line

2. U Baffle Ceiling Production Line

3. Linear Strip Ceiling Production Line

4. Open Cell Ceiling Production Line

And so on...

What Can We Supply?

What Can We Supply?

1.Provide Installation Services

In order to help our customers to solve machine installation problems, KINGREAL will provide both online and local installation services.

2. Technical Support

KINGREAL is able to provide technical after-sales service to our customers.

In order to ensure the smooth installation and operation of the machines, KINGREAL will arrange to send engineers to the customer‘s project for technical guidance.

Up to now, KINGREAL has helped customers from Russia, Mexico, India and Saudi Arabia to use the machines smoothly.