KINGREAL 150mm Metal Baffle Ceiling Production Line is our specialized product for those who wants to produce small sizes U-shape baffles. It is the best choice for a budget baffle ceiling making solution. Main components of the line: hydraulic decoiler, precision straightener, main roll forming machine, hydraulic follow shearing station, product output table and electrical control system.

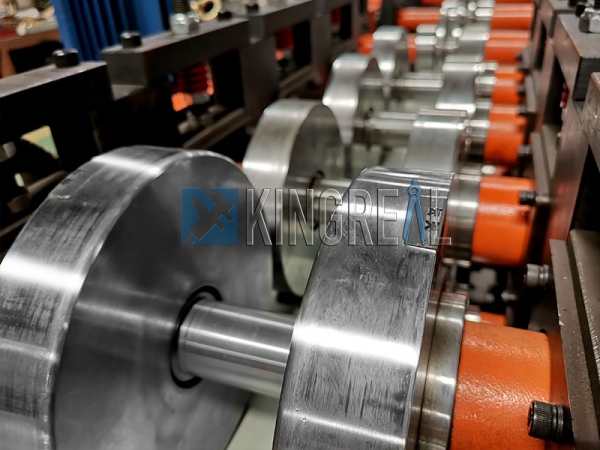

Although this production line can only produce as half the maximum size comparing with our 300mm baffle ceiling production line, it still has all characteristics of our baffle ceiling production line series. Including high-quality main roll forming machine - Cr12MoV-mold-steel-made rollers for precision roll forming, more than 20mm thickness of machine structure to ensure long time working, adjustable baffle sizes from 30mm to 150mm powered by PLC control system.

Yes, it‘s still here - the hydraulic decoiler. It provides high efficiency and hydraulic expansion for raw materail coils, which speed up the whole production line. Also, it is compatible with painted raw material coil to produce U-shape baffle.

Classic hydraulic-powered follow shearing station, with air-cooling system to cool down, and servo motor from famous Japanese brand YASKAWA. Stable station structure for durable product shearing, Cr12MoV mold steel for precision shearing. All quality parts and components to ensure semi-finished products can be cut accurately.

Baffle sizes can be adjusted as per requirement from customer. Also, we have production line to make ceiling carriers specially for baffle ceilings. Together, baffle and carrier can combine a baffle ceiling system.