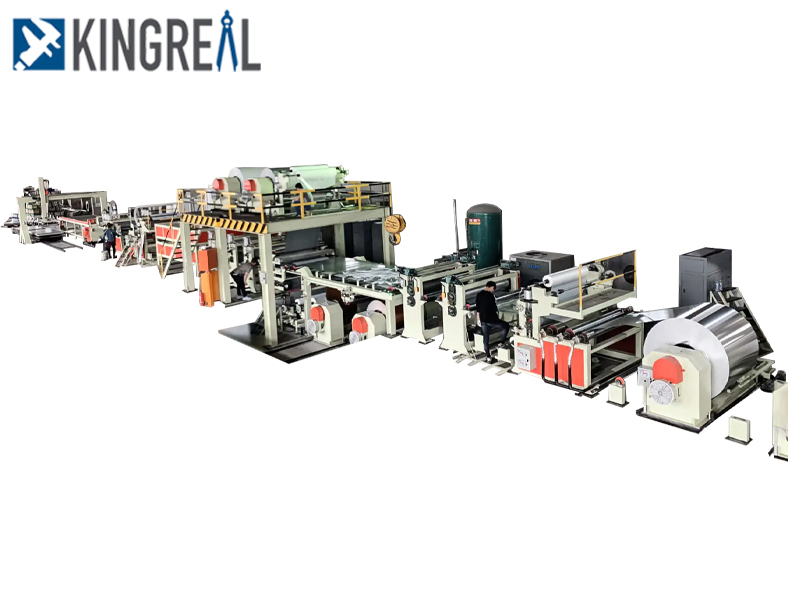

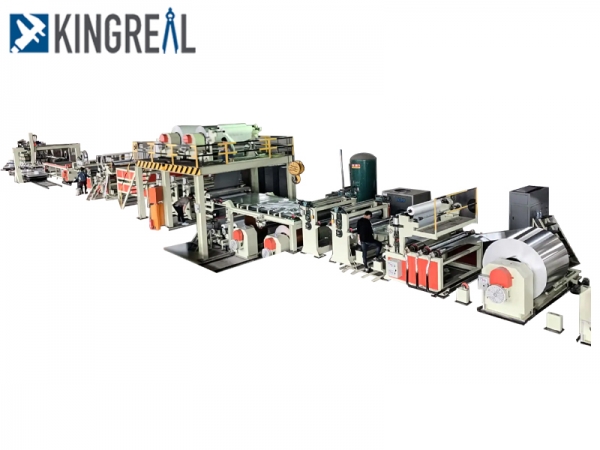

Metal honeycomb panels are high-strength, lightweight, and have excellent sound and heat insulation properties, and are widely used in many industries. The complete aluminium honeycomb composite panel making process is complex and has a higher requirements for machine technology. After in-depth research and development and testing, KINGREAL‘s technical team has polished the technical details of various aluminium honeycomb sandwich panel production technologies and developed a new aluminium honeycomb composite panel production line. We can customize the manufacturing machine according to your production needs, and are committed to providing you with the most suitable and cost-effective metal honeycomb panel production line.

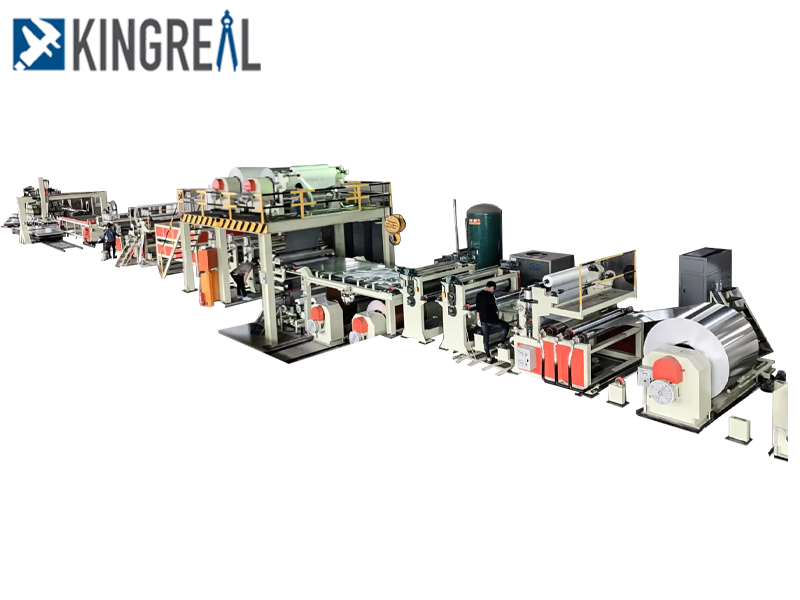

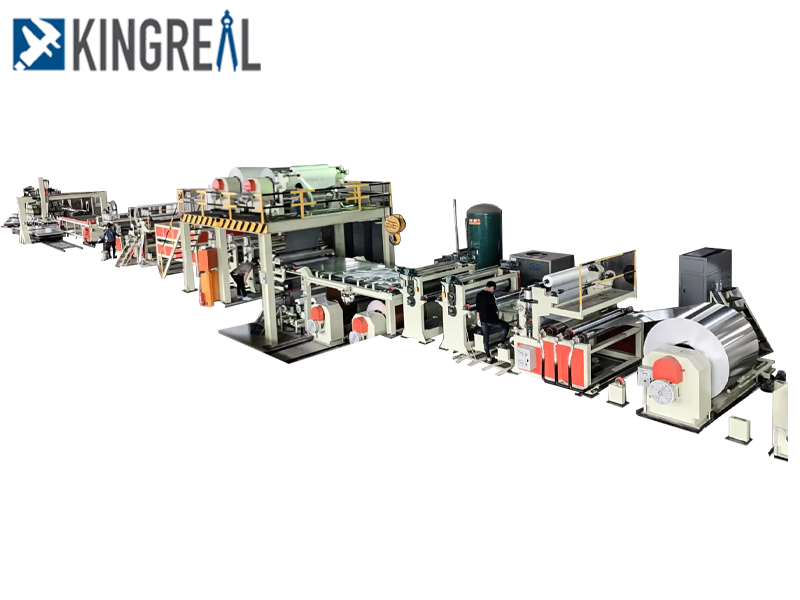

KINGREAL provide metal honeycomb basic panel making machine, cold press machine, hot press machine, and gluing machine for you to choose to equip on the aluminium honeycomb composite panel production line. Different components are responsible for different processes of the panel, and finally can be combined into a complete aluminum honeycomb sheet.

decoiling - leveling - roll forming and bending - cutting and bending - gluing section - metal honeycomb core assemblies - single board covering on top - heated press/cold press - product output

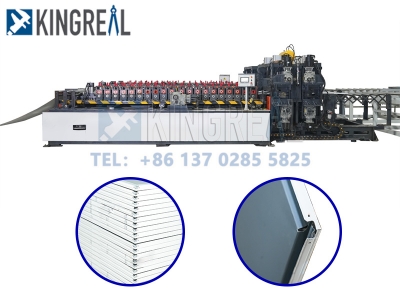

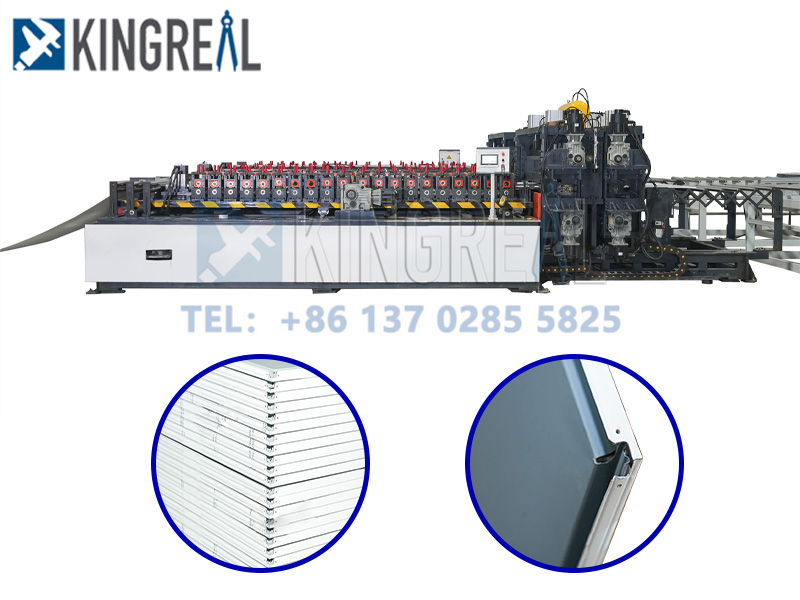

This machine is used to manufacture the base panels of metal honeycomb panels. It is fully automated and requires only a small amount of manual operation, ensuring the accuracy of production. Both the feed material and panel size can be customized according to your production needs.

| Main Features: 1.Flexible production The width and length of the honeycomb aluminium sheet can be adjusted by CNC. Moreover, the size can be can be customized. The production process is highly automated without the hassle of increasing labor costs. 2.High degree of automation KINGREAL basic metal honeycomb panel making machine adopts automatic mechanized production method, has a strong stability and consistency of the products produced. |

|

Specification

| Raw materials | Aluminum, Steel (Can be customized) |

| Material thickness | surface 0.28mm; back 0.18mm |

| Forming roller | 20 |

| Running speed | 4-6m/min |

| Profile size | 600/900/1200*11.7mm (Can be customized) |

| Profile precision | ±0.2mm |

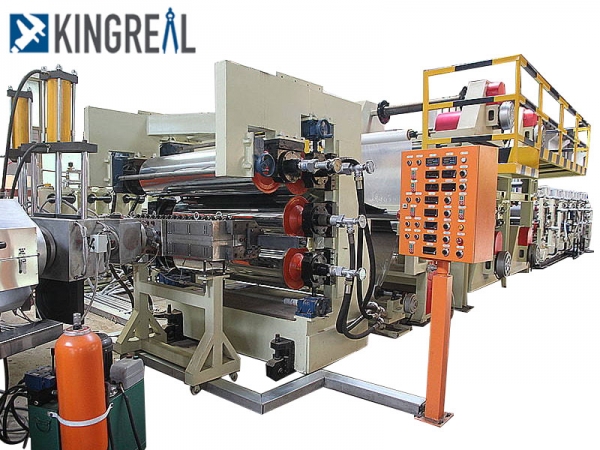

Automatic Gluing Machine for Honeycomb Aluminium Sheet

This fully automatic honeycomb aluminium sheet gluing machine is used to automatically coat glue onto the basic metal honeycomb panel, and the panel coated with glue can be directly sent to the next process.

| Main Features: 1. Uniform glue coating The roller is made of high-hardness metal and is tightly processed by a grinder. It can clamp the basic metal honeycomb panel to prevent uneven glue coating caused by panel misalignment. 2.Thickened glue roller The glue roller is thickened to make it more oil-resistant and wear-resistant, extending its service life. |

|

Specification

| Mechanical specification | can be designed according to the requirements of the plates |

| Width of the plate | 300-1200mm |

| Length of the plate | 500-4000mm |

| Thickness of the plate | 0.5-50mm |

| The amount of the sheet glue on one side | 120g-350g adjustable |

| Production speed | 0-8m/min adjustable |

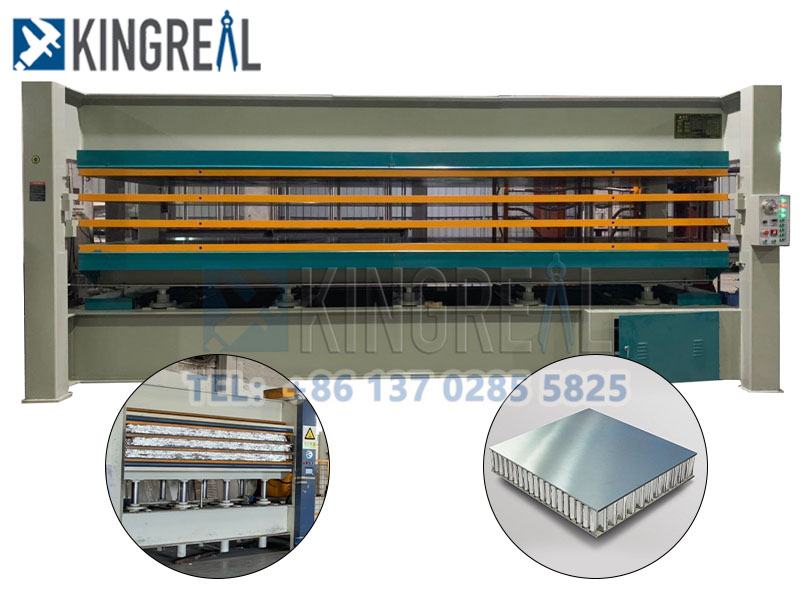

Honeycomb Sheet Hot Pressing Machine

The honeycomb sheet hot pressing machine is used to make the composite panel with metal honeycomb core and two basic panels assembled achieve the bonding effect under high temperature and high pressure by utilizing the changes in temperature and pressure.

| Main Features: 1.Air cooling system A forced air cooling system is configured to effectively reduce the operating temperature of the hydraulic system, to achieve continuous operation. 2.High hardness hot pressed panel The hot pressed panels are made of high-hardness materials and can withstand continuous, high-pressure operations. |

|

Specification

| Total pressure | 1600-2000Kn |

| Number of plates | 4-6 |

| Closing speed | 40mm/s |

| Plate spacing | 100mm |

Honeycomb Sheet Cold Press Machine

Cold pressing is suitable for manufacturers who require higher surface flatness of aluminum honeycomb sandwich panel. During the cold press process, higher pressure can improve the plastic deformation ability of the material, while lower temperature helps to reduce the rebound and deformation of the material. By controlling the changes in pressure and temperature, the cold press can meet different metal honeycomb panel processing requirements.

| Main Features: 1.High hardness fuselage The fuselage is welded and formed from steel plates, and the fuselage is thickened, improved machine stability, supporting long-term continuous production. 2.Integrated oil cylinder The machines all use integrated oil cylinders to ensure long-term operation without oil leakage and good pressure-maintaining effects. 3.Pressure plate balancing mechanism The rotating shaft rotates flexibly. The rack engages and rotates so that the pressure plate always maintains balance during the lifting process. |

|

Specification

| Platen size | 1225*2500mm |

| Pressure | 50-100T |

| Platen thickness | 1000-1500mm |

| Platen height | 1000mm |

The production of aluminium honeycomb sandwich panel is known for its diversity and high difficulty. After research and development and multiple tests, the KINGREAL technical team has improved various technical details on the original basis to ensure that the function of each component is optimal. From the manufacturing of basic metal honeycomb panel to glue application and hot/cold pressing, every component is used to its maximum effect to bring maximum benefits to our customers. KINGREAL provides customers with customized manufacturing services. You can choose different components to form your aluminium honeycomb composite panel production line according to specific production needs. You just need to tell us your production needs or send us sample drawings, and we will develop a suitable machine production plan for you.

To integrate R&D, KINGREAL has established our own factory, located in Foshan, Guangdong. In addition to maintaining close contact online, many of our customers also choose to visit our factory to observe the production of machines and communicate with us face to face. We are looking forward to reaching long-term and stable relationships with customers around the world with our professional capability and consistent level of service!