"Who Are We?"

KINGREAL CEILING MACHINERY is a professional supplier with more than 20 years of rich experience in the machinery manufacturing industry. KINGREAL CEILING MACHINERY production lines can process different types of materials (steel, iron, stainless steel, galvanized, aluminum, brass, copper). Our main products include Metal Ceiling Tile Production Line, Metal Perforated Making Machine, Baffle Ceiling Roll Forming Machine, Ceiling T Bar Machine, Open Cell Ceiling Machine, Linear Strip Ceiling Machine, etc.

KINGREAL CEILING MACHINERY factory is located in Foshan, a important manufacturing base in China. KINGREAL CEILING MACHINERY has an experienced team of engineers and skilled production and testing personnel. At the same time, Our customer reception team will provide you with professional services and detailed explanations. So far, we has received nearly 5,000 customers to visit our factory and facilitated a number of cooperations.

KINGREAL CEILING MACHINERY has always been committed to providing high-quality products and first-class services, constantly learning cutting-edge technologies and promoting technological innovation.

★Metal Ceiling production line has achieved a transition from semi-automatic to fully automatic.

★The baffle ceiling roll forming machine has launched a 300 model according to customer needs.

★Ceiling T bar machine has added a protective hood to extend the service life of the machine.

KINGREAL CEILING MACHINERY has sold more than 3,000 machines and our products are exported to more than 50 countries around the world, including Russia, India, Indonesia, the United States and Canada, and have established good relationships with stable partners.KINGREAL CEILING MACHINERY will continue to focus on the field of machine manufacturing to bring customers a better experience. Welcome to visit the KINGREAL CEILING MACHINERY factory!

"What Can We Do?"

KINGREAL CEILING MACHINERY is a factory specializing in the field of Suspended Ceiling Machines within the KINGREAL MACHINERY Head Office. KINGREAL CEILING MACHINERY has continued to innovate and develop in the field of Metal Ceiling Tile Production Line And Suspended Ceiling Forming Machine, and has expanded its business to include related ceiling spare parts equipment, False Ceiling Channel Roll Forming Machine, and Metal Perforating Machine.KINGREAL CEILING MACHINERY continues to specialize and develop in the field of machine manufacturing, and strives to provide customers with complete production solutions.

Metal ceiling production line is through a series of processes such as unwinding, leveling, punching, cutting, forming, etc., for the production of different sizes (30*30cm, 60*60cm, 60*120cm, etc.) and types (clip in metal ceiling tile, lay in metal ceiling tile, tegular metal ceiling tile, etc.) decorative ceiling tiles.

In order to better meet the needs of different customers, KINGREAL CEILING MACHINERY metal ceiling tile production line has two kinds of automatic and semi-automatic equipment for customers to choose.

A metal ceiling tile production line from KINGREAL CEILING MACHINERY can produce different types and sizes of metal ceiling tiles, you only need to change different molds to achieve this. The replacement of the mold is very convenient, saving time and the cost of buying other metal ceiling machines.

In order to complete the production more efficiently, KINGREAL CEILING MACHINERY can also provide the feeding trolley and the automatic tiles feeding machine for metal ceiling machine.

Suspended Ceiling Roll Forming Machine

Suspended Ceiling Production Line is mainly composed of decoiler, straightener, cutting machine, roll forming machine and other precision components. Used to produce different sizes, types of baffle, linear strip, grilyato and other suspended ceiling.

In order to meet the needs of customers for more efficient production, KINGREAL CEILING MACHINERY introduced the 300mm baffle ceiling machine for greater height and width range, the high configuration open cell ceiling machine for punching the entire production line in one go, and the adjustable width and narrow linear strip ceiling machine for the production of different sizes of linear strip ceilings.

If you have other special requirements, you are welcome to send drawings to KINGREAL CEILING MACHINERY. Engineers will give customized solutions after full communication with you to meet your production needs for different finished product sizes, styles and thicknesses.

Metal Perforated Making Machine

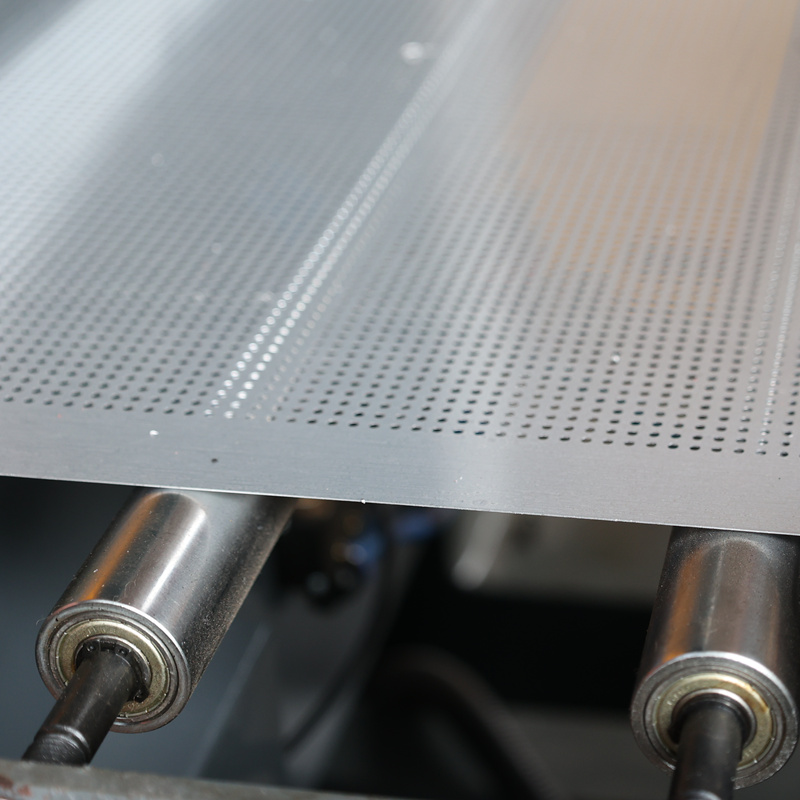

Metal perforating machine is a metal sheet material as raw materials through the decoiler, precision leveling machine, punching machine, cutting station and other components to punch a variety of holes in the raw material.

KINGREAL CEILING MACHINERY one production line can produce different perforation sizes and shapes for you to make metal perforated board, perforated metal pipe, perforated ceiling tile and other finished products.

And KINGREAL CEILING MACHINERY can provide you with high speed presses up to 180SPM. The metal perforating machine can be used with the metal ceiling tile production line and a variety of roll forming machines to produce a complete ceiling system for you.

If there are special production requirements, KINGREAL CEILING MACHINERY will make the necessary adjustments to the metal perforation line according to the customer's drawings and actual production requirements to obtain the final perforation plate.

"Philosophy & Mission & Vision"

Philosophy

KINGREAL CEILING MACHINERY is committed to providing efficient and reliable machine manufacturing solutions to global customers through advanced technology and high-quality products. KINGREAL CEILING MACHINERY‘s core values are innovation, integrity and sustainable development.

Mission

- Provide international customers with high-performance, customized machines and equipment to meet diverse needs.

- Continuously improve machine production processes to ensure product quality and delivery efficiency.

- Through excellent customer service, establish long-term partnerships and help customers achieve success.

Vision

KINGREAL CEILING MACHINERY's vision is to become a leader in the global machine manufacturing industry, drive industry development with innovation and sustainability, and become the preferred partner of customers. KINGREAL CEILING MACHINERY hopes to achieve a smarter and more efficient future of manufacturing through technological innovation.

Get the latest price? We'll respond as soon as possible(within 12 hours)

What customers says