Products Lists

1. What is a Sheet Metal Perforation Machine?

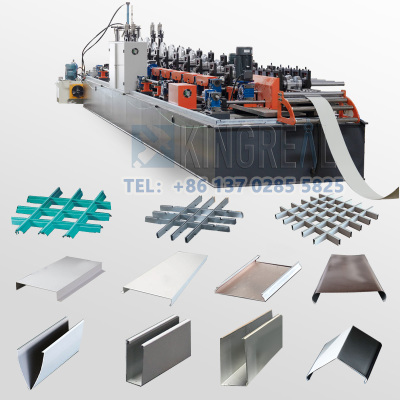

A perforated metal machine is a device specially designed to process metal coils into different hole diameters and hole types. Through this process, customers can obtain metal perforated plates that meet specific specifications according to their production needs. These perforated plates are widely used in many industries, covering a wide range of fields such as construction, automobiles, home appliances, and electronics.

A complete sheet metal perforating machine usually consists of multiple precision components, including decoilers, levelers, metal punching machines, recoilers, or cutting stations. The coordinated work of these components ensures the efficiency of the production process and the quality of the products. The design of the metal sheet perforated machine not only takes into account the processing performance, but also emphasizes the degree of automation to minimize manual intervention and improve production efficiency.

KINGREAL CEILING MACHINERY metal perforating machine has worked closely with customers from all over the world, including India, the United States, the United Arab Emirates, Egypt, Canada and many other countries.

2. Advantages of Metal Sheet Perforated Machine

(1) Fully automated

The metal perforated making machine provided by KINGREAL CEILING MACHINERY consists of fully automatic precision components that can operate with almost no human intervention. This fully automated design significantly improves the efficiency of the punching process. If customers need further automation solutions, KINGREAL CEILING MACHINERY can also provide additional components such as feeding trolleys and metal sheet cleaning machines to ensure seamless connection of the entire punching process. This advantage of automation not only improves production efficiency, but also reduces human errors, improving product consistency and quality.

(2) Fast punching speed

KINGREAL CEILING MACHINERY steel perforated machine performs well in stroke, usually reaching 100-180 SPM. If customers have higher requirements for stroke, please inform KINGREAL CEILING MACHINERY of the specific drawings and production conditions, and the engineers will design a suitable high-stroke sheet metal perforation machine according to actual needs. This flexibility ensures that the equipment can meet the changes in different production environments and customer needs.

(3) Precision leveling

The flatness of the metal coil directly affects the quality of subsequent punching, so KINGREAL CEILING MACHINERY is equipped with a precision leveling machine for the perforated metal machine. The leveling machine consists of 9 rollers, 4 on the upper and 5 on the lower, which can effectively correct the deformation of the metal coil and ensure the flatness of the plate during the punching process. This high-precision leveling system lays the foundation for high-quality punching products.

3. KINGREAL CEILING MACHINERY can Provide Customized Perforated Metal Machine Solutions

KINGREAL CEILING MACHINERY engineers design a variety of metal sheet perforated machine solutions based on the different process requirements of customers. According to different process requirements, KINGREAL CEILING MACHINERY divides the metal perforated making machine into three models, and the specific parameters and components can be adjusted and customized according to the actual situation of the customer.

(1) Coil to coil perforation line

In 2024, KINGREAL CEILING MACHINERY recommended a coil to coil perforation line for Brazilian customers. After the metal coil is punched, the equipment will automatically rewind, eliminating the trouble of manual rewinding. The biggest advantage of this coil to coil perforated making machine is that it solves the Brazilian customer's concerns about the surface scratching of the perforated metal coil during long-distance transportation. At the same time, customers can use the wound perforated metal coil to produce perforated filter screens. After using it, Brazilian customers have given good feedback. At present, this coil to coil perforated making machine is still operating efficiently in its factory, effectively improving production efficiency.

(2) Metal sheet perforated machine

At a Canton Fair, KINGREAL CEILING MACHINERY established contact with an Iranian customer. This customer is a perforated wall panel manufacturer and clearly stated that he needed to buy a high-speed metal perforated making machine. KINGREAL CEILING MACHINERY displayed previous successful cases at the booth, gained the customer's trust, and agreed to visit KINGREAL CEILING MACHINERY factory. During the factory visit, the Iranian customer expressed satisfaction with the cutting station equipped by KINGREAL CEILING MACHINERY for the steel perforated machine, and witnessed how the equipment accurately cuts the perforated metal sheet and adjusts the length of the perforated metal sheet on the control panel according to customer needs. All this makes the customer feel deeply confident in the technical capabilities of KINGREAL CEILING MACHINERY.

(3) Metal ceiling tile perforation line

A Bangladeshi customer previously purchased a metal ceiling machine from KINGREAL CEILING MACHINERY. As the production scope expanded, his demand for perforated ceilings increased. So he found KINGREAL CEILING MACHINERY again, hoping to equip the corresponding perforated metal machine according to the parameters of its metal ceiling production line. KINGREAL CEILING MACHINERY engineers responded positively and asked the customer about the specific parameter requirements for metal perforated ceilings, including information such as punching speed. The sheet metal perforating machine designed in the end perfectly matched the customer's previous metal ceiling machine, successfully produced high-precision perforated ceilings, and met the customer's needs.

4. KINGREAL CEILING MACHINERY innovation in metal sheet perforated machines

In the field of metal perforated making machine manufacturing, it is extremely difficult to manufacture micro perforation molds, so the common punching apertures on the market are generally 1.8mm and 2.5mm. KINGREAL CEILING MACHINERY is constantly innovating in technology to meet customers' needs for small hole punching. For example, KINGREAL CEILING MACHINERY designed a steel perforated machine capable of punching 1.5mm holes for Moroccan customers, and more impressively, provided a perforated metal machine capable of punching 1.0mm holes for Greek customers. This not only demonstrates KINGREAL CEILING MACHINERY breakthrough in mold precision technology, but also reflects its ability to respond quickly to customer needs.

✦The difficulty of manufacturing micro perforation molds is mainly reflected in the following aspects:

(1) Material selection: High-hardness, wear-resistant materials are required to make small hole molds to ensure that the molds maintain performance and precision under high-intensity operations. The choice of materials directly affects the life of the mold and the quality of punching.

(2) Processing technology: The processing of micro perforation molds requires extremely high precision, and any slight error will result in the failure of the final product. Therefore, during the processing, high-precision CNC machine tools and advanced processing technologies such as EDM are required.

(3) Die design: The design of the small hole die must take into account the fluid mechanics of the punching to ensure the fluidity of the metal material during the punching process. This requires the designer to have rich experience and deep expertise.

5. Application Fields of Perforated Metal Machine

The application fields of metal sheet perforated machine are wide, covering almost all walks of life. Here are some of the main application areas:

(1) Perforated wall panels

Punching wall panels are widely used in the construction industry, both as structural materials and for decoration. Through punching, wall panels can effectively reduce weight while maintaining strength, and are an important part of modern architecture.

(2) Perforated filters

Punching filters have important applications in water treatment, air purification and other fields. These filters ensure effective filtration of impurities and improve the purity of the fluid through precise punching design.

(3) Perforated mufflers

In automobiles and mechanical equipment, perforated mufflers can effectively reduce noise and improve the working environment. Through specific punching design, the muffler can achieve better acoustic effects.

(4) Perforated bread trays

Punched bread trays are widely used in the food industry. They provide good ventilation and ensure the quality of baked goods such as bread. At the same time, the punching design also makes the trays easier to clean and maintain.

(5) Perforated screens

In interior decoration, perforated screens not only have practical functions, but also add beauty. Through different punching patterns, the screens can create unique visual effects and meet personalized needs.

A perforated metal machine is a device specially designed to process metal coils into different hole diameters and hole types. Through this process, customers can obtain metal perforated plates that meet specific specifications according to their production needs. These perforated plates are widely used in many industries, covering a wide range of fields such as construction, automobiles, home appliances, and electronics.

A complete sheet metal perforating machine usually consists of multiple precision components, including decoilers, levelers, metal punching machines, recoilers, or cutting stations. The coordinated work of these components ensures the efficiency of the production process and the quality of the products. The design of the metal sheet perforated machine not only takes into account the processing performance, but also emphasizes the degree of automation to minimize manual intervention and improve production efficiency.

KINGREAL CEILING MACHINERY metal perforating machine has worked closely with customers from all over the world, including India, the United States, the United Arab Emirates, Egypt, Canada and many other countries.

2. Advantages of Metal Sheet Perforated Machine

(1) Fully automated

The metal perforated making machine provided by KINGREAL CEILING MACHINERY consists of fully automatic precision components that can operate with almost no human intervention. This fully automated design significantly improves the efficiency of the punching process. If customers need further automation solutions, KINGREAL CEILING MACHINERY can also provide additional components such as feeding trolleys and metal sheet cleaning machines to ensure seamless connection of the entire punching process. This advantage of automation not only improves production efficiency, but also reduces human errors, improving product consistency and quality.

(2) Fast punching speed

KINGREAL CEILING MACHINERY steel perforated machine performs well in stroke, usually reaching 100-180 SPM. If customers have higher requirements for stroke, please inform KINGREAL CEILING MACHINERY of the specific drawings and production conditions, and the engineers will design a suitable high-stroke sheet metal perforation machine according to actual needs. This flexibility ensures that the equipment can meet the changes in different production environments and customer needs.

(3) Precision leveling

The flatness of the metal coil directly affects the quality of subsequent punching, so KINGREAL CEILING MACHINERY is equipped with a precision leveling machine for the perforated metal machine. The leveling machine consists of 9 rollers, 4 on the upper and 5 on the lower, which can effectively correct the deformation of the metal coil and ensure the flatness of the plate during the punching process. This high-precision leveling system lays the foundation for high-quality punching products.

3. KINGREAL CEILING MACHINERY can Provide Customized Perforated Metal Machine Solutions

KINGREAL CEILING MACHINERY engineers design a variety of metal sheet perforated machine solutions based on the different process requirements of customers. According to different process requirements, KINGREAL CEILING MACHINERY divides the metal perforated making machine into three models, and the specific parameters and components can be adjusted and customized according to the actual situation of the customer.

(1) Coil to coil perforation line

In 2024, KINGREAL CEILING MACHINERY recommended a coil to coil perforation line for Brazilian customers. After the metal coil is punched, the equipment will automatically rewind, eliminating the trouble of manual rewinding. The biggest advantage of this coil to coil perforated making machine is that it solves the Brazilian customer's concerns about the surface scratching of the perforated metal coil during long-distance transportation. At the same time, customers can use the wound perforated metal coil to produce perforated filter screens. After using it, Brazilian customers have given good feedback. At present, this coil to coil perforated making machine is still operating efficiently in its factory, effectively improving production efficiency.

(2) Metal sheet perforated machine

At a Canton Fair, KINGREAL CEILING MACHINERY established contact with an Iranian customer. This customer is a perforated wall panel manufacturer and clearly stated that he needed to buy a high-speed metal perforated making machine. KINGREAL CEILING MACHINERY displayed previous successful cases at the booth, gained the customer's trust, and agreed to visit KINGREAL CEILING MACHINERY factory. During the factory visit, the Iranian customer expressed satisfaction with the cutting station equipped by KINGREAL CEILING MACHINERY for the steel perforated machine, and witnessed how the equipment accurately cuts the perforated metal sheet and adjusts the length of the perforated metal sheet on the control panel according to customer needs. All this makes the customer feel deeply confident in the technical capabilities of KINGREAL CEILING MACHINERY.

(3) Metal ceiling tile perforation line

A Bangladeshi customer previously purchased a metal ceiling machine from KINGREAL CEILING MACHINERY. As the production scope expanded, his demand for perforated ceilings increased. So he found KINGREAL CEILING MACHINERY again, hoping to equip the corresponding perforated metal machine according to the parameters of its metal ceiling production line. KINGREAL CEILING MACHINERY engineers responded positively and asked the customer about the specific parameter requirements for metal perforated ceilings, including information such as punching speed. The sheet metal perforating machine designed in the end perfectly matched the customer's previous metal ceiling machine, successfully produced high-precision perforated ceilings, and met the customer's needs.

4. KINGREAL CEILING MACHINERY innovation in metal sheet perforated machines

In the field of metal perforated making machine manufacturing, it is extremely difficult to manufacture micro perforation molds, so the common punching apertures on the market are generally 1.8mm and 2.5mm. KINGREAL CEILING MACHINERY is constantly innovating in technology to meet customers' needs for small hole punching. For example, KINGREAL CEILING MACHINERY designed a steel perforated machine capable of punching 1.5mm holes for Moroccan customers, and more impressively, provided a perforated metal machine capable of punching 1.0mm holes for Greek customers. This not only demonstrates KINGREAL CEILING MACHINERY breakthrough in mold precision technology, but also reflects its ability to respond quickly to customer needs.

✦The difficulty of manufacturing micro perforation molds is mainly reflected in the following aspects:

(1) Material selection: High-hardness, wear-resistant materials are required to make small hole molds to ensure that the molds maintain performance and precision under high-intensity operations. The choice of materials directly affects the life of the mold and the quality of punching.

(2) Processing technology: The processing of micro perforation molds requires extremely high precision, and any slight error will result in the failure of the final product. Therefore, during the processing, high-precision CNC machine tools and advanced processing technologies such as EDM are required.

(3) Die design: The design of the small hole die must take into account the fluid mechanics of the punching to ensure the fluidity of the metal material during the punching process. This requires the designer to have rich experience and deep expertise.

5. Application Fields of Perforated Metal Machine

The application fields of metal sheet perforated machine are wide, covering almost all walks of life. Here are some of the main application areas:

(1) Perforated wall panels

Punching wall panels are widely used in the construction industry, both as structural materials and for decoration. Through punching, wall panels can effectively reduce weight while maintaining strength, and are an important part of modern architecture.

(2) Perforated filters

Punching filters have important applications in water treatment, air purification and other fields. These filters ensure effective filtration of impurities and improve the purity of the fluid through precise punching design.

(3) Perforated mufflers

In automobiles and mechanical equipment, perforated mufflers can effectively reduce noise and improve the working environment. Through specific punching design, the muffler can achieve better acoustic effects.

(4) Perforated bread trays

Punched bread trays are widely used in the food industry. They provide good ventilation and ensure the quality of baked goods such as bread. At the same time, the punching design also makes the trays easier to clean and maintain.

(5) Perforated screens

In interior decoration, perforated screens not only have practical functions, but also add beauty. Through different punching patterns, the screens can create unique visual effects and meet personalized needs.

Get the latest price? We'll respond as soon as possible(within 12 hours)