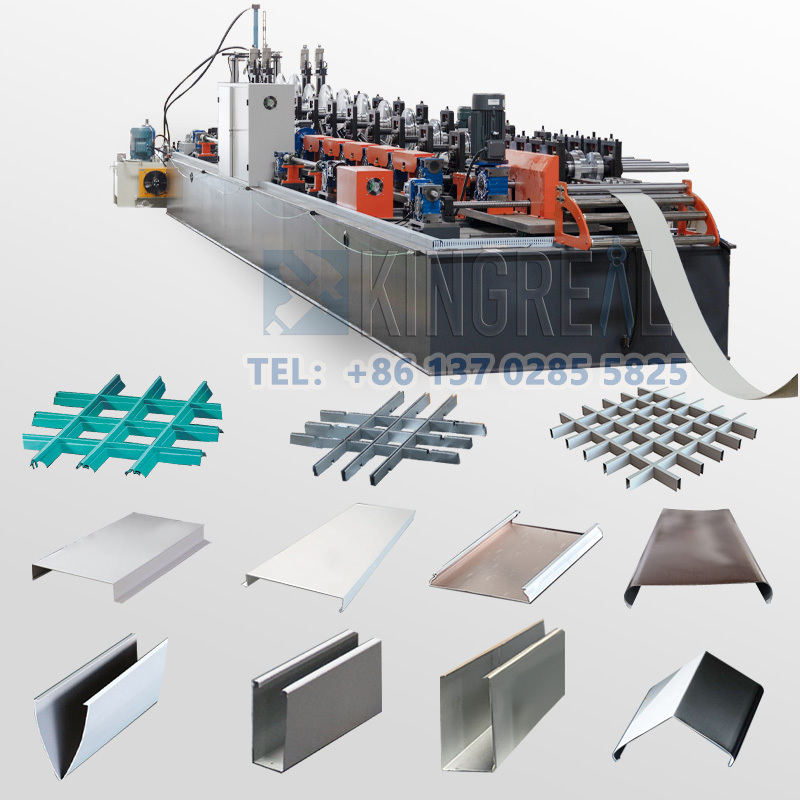

Suspended Ceiling Roll Forming Machine

KINGREAL CEILING MACHINERY has more than 20 years of rich experience in the suspended ceiling machine manufacturing industry. KINGREAL CEILING MACHINERY can provide you with customized complete ceiling system solutions according to your needs.

- KINGREAL CEILING MACHINERY

- China

- 90 Days

- 9999

Details

Video Display About Suspended Ceiling Machine

Suspended Ceiling Tile Making Machine

KINGREAL CEILING MACHINERY has more than 20 years of rich experience in the suspended ceiling machine manufacturing industry. KINGREAL CEILING MACHINERY can provide you with customized complete ceiling system solutions according to your needs.

KINGREAL CEILING MACHINERY has roll forming machines such as baffle ceiling machines, linear strip ceiling machines, open cell ceiling machines, etc. to meet your production needs for different finished product sizes, styles, and thicknesses. Among them, the featured machines are 300mm u baffle machine, width adjustable linear strip ceiling machine, and high-end open cell ceiling machine.

|  |  |

KINGREAL CEILING MACHINERY has an experienced team of engineers and skilled production and testing personnel. At the same time, KINGREAL CEILING MACHINERY’s customer reception team will provide you with professional services and detailed explanations. So far, KINGREAL CEILING MACHINERY has received nearly 10,000 customers to visit our factory and facilitated a number of cooperations.

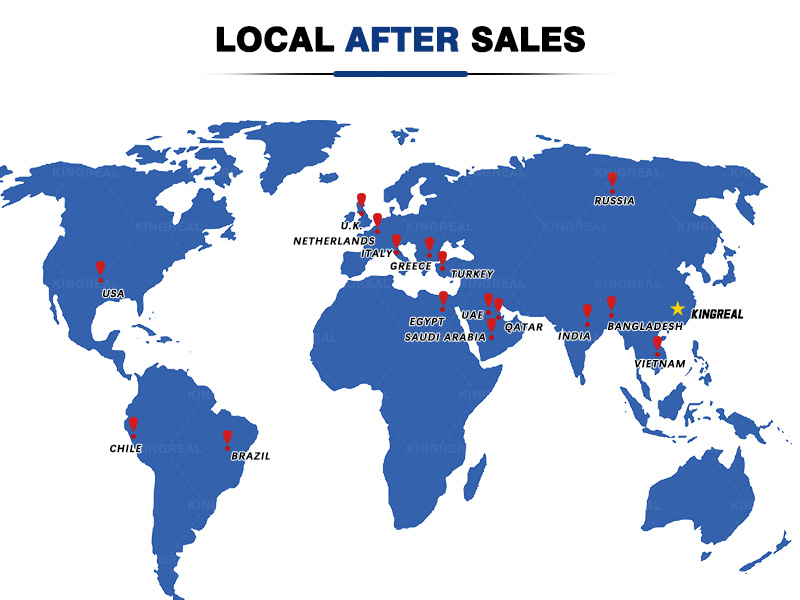

KINGREAL CEILING MACHINERY machines have been exported to many countries around the world, including Russia, India, the United States, Canada, etc., and have established good relationships with stable partners. KINGREAL CEILING MACHINERY will continue to focus on the field of machine manufacturing to bring customers a better experience. |  |

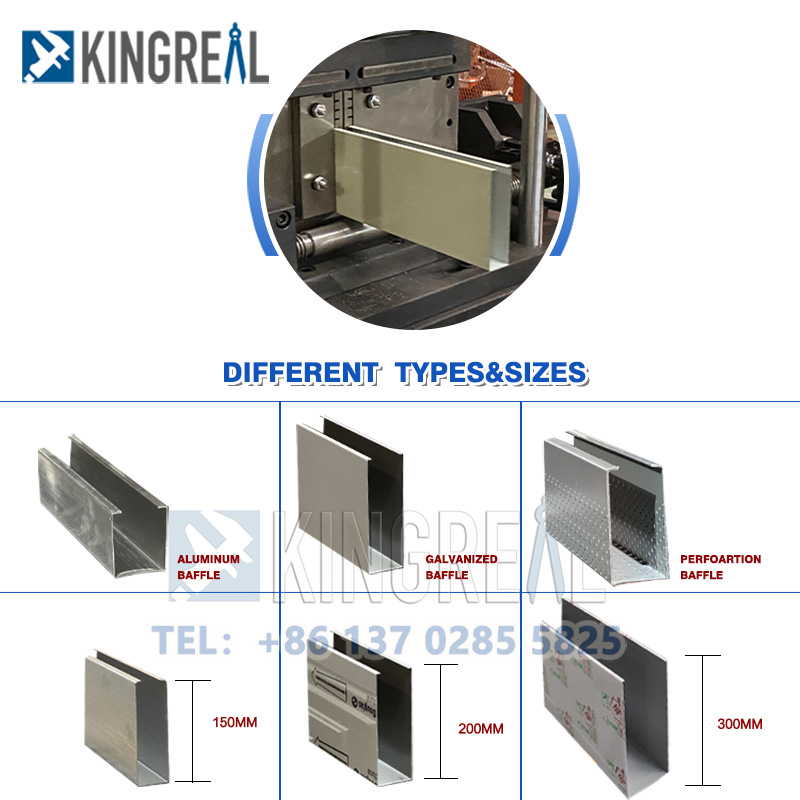

Baffle Ceiling Making Machine

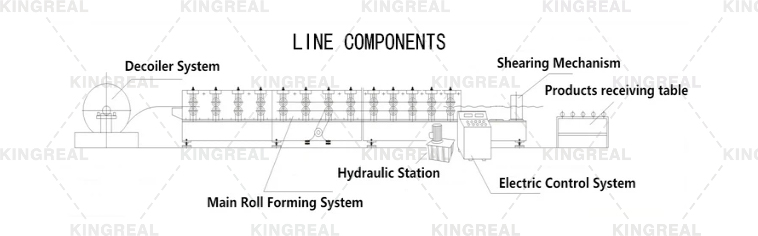

The u baffle machine uses metal sheets as raw materials and can produce common metal baffle ceilings, such as U-shaped baffles, acoustic baffles, and V-shaped baffles. The u baffle metal ceiling machine mainly consists of a hydraulic decoiler, a precision straightener, a main roll forming machine, a product table, an electrical system, a hydraulic system, and a shearing system.

KINGREAL CEILING MACHINERY u baffle ceiling machines have three models. The 150mm baffle ceiling machine can produce baffles with a height range of 35-150mm and a width range of 30-100mm; the 200mm baffle ceiling machine can produce baffles with a height range of 35-200mm and a width range of 30-100mm; the 300mm baffle ceiling machine can produce baffles with a height range of 35-300mm and a width range of 50-100mm.

Linear Strip Ceiling Machine

KINGREAL CEILING MACHINERY linear strip ceiling machine can not only make R84, but also customize linear strip ceilings in shapes such as C/G/F/B/S. The linear strip ceiling production line is mainly composed of decoiler, precision straightener, main roll forming machine, product table and other equipment.

KINGREAL CEILING MACHINERY linear strip ceiling machine has three types: adjustable width, standard and economical. The adjustable width linear strip ceiling machine is suitable for producing linear strip ceilings of different sizes. The standard linear strip ceiling machine can meet the production needs of high-precision linear strip ceilings, and the economical linear strip ceiling machine is only suitable for processing thin metal sheets. You can choose according to your production needs.

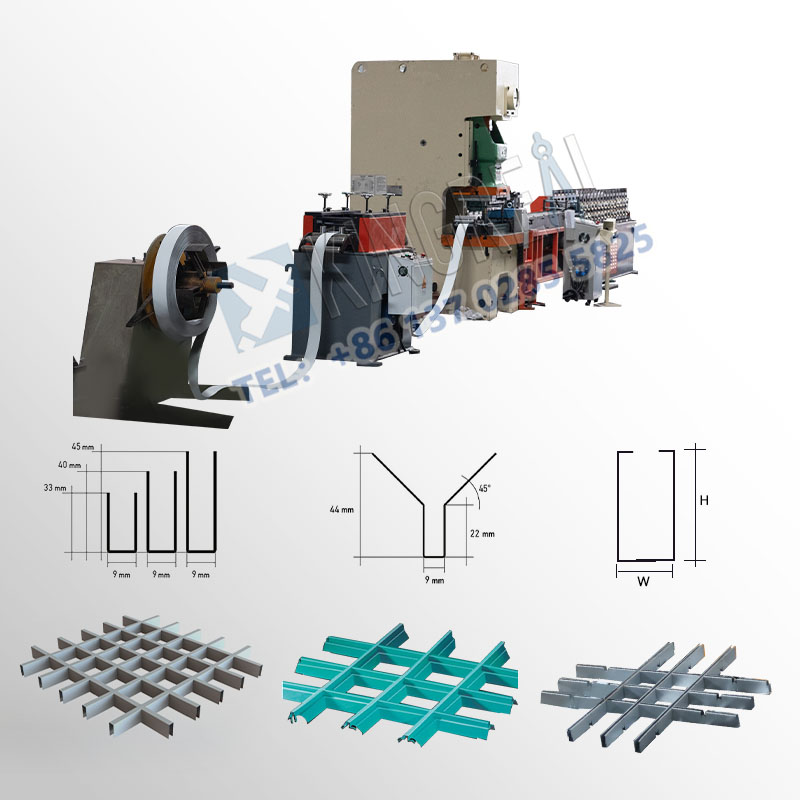

Open Cell Ceiling Machine

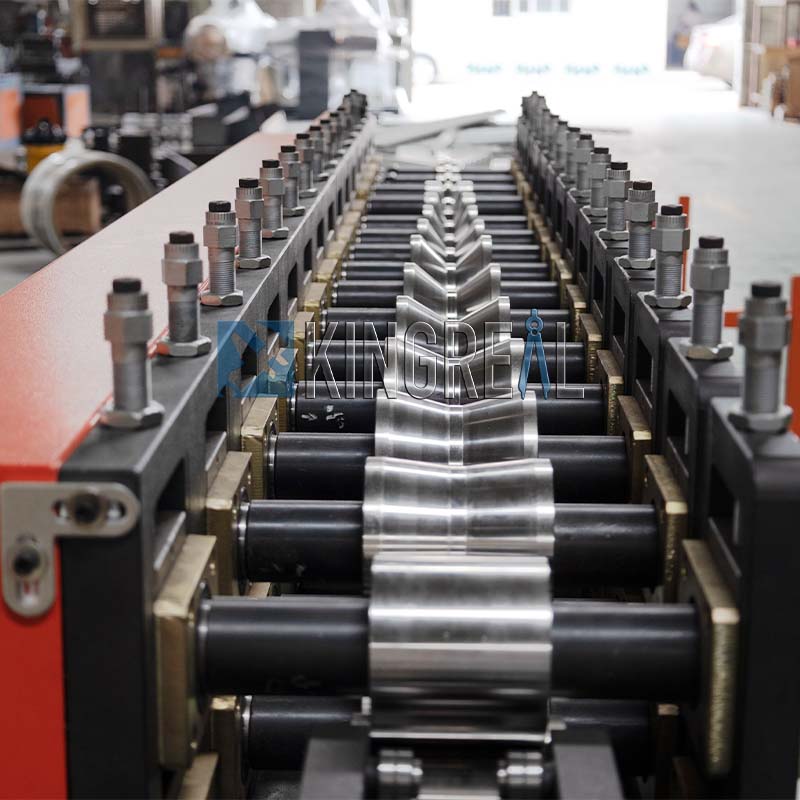

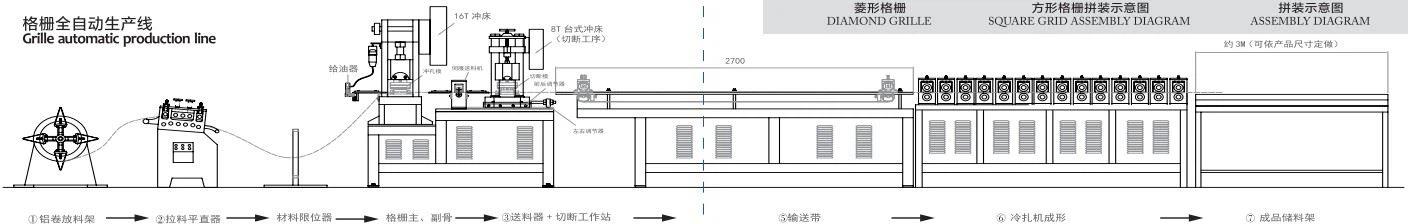

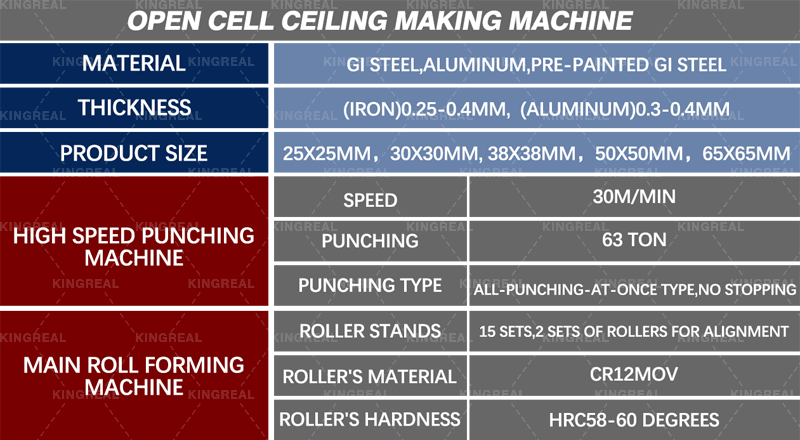

KINGREAL CEILING MACHINERY open cell ceiling machine can produce grid ceilings of different sizes and types such as U-shaped, C-shaped, pyramid, etc., and one grilyato ceiling production line can be compatible with both iron and aluminum metal raw materials. The main components of the machine are decoiler, punching station, cut-to-length press machine and main roll forming machine.

KINGREAL CEILING MACHINERY open cell ceiling machine has standard grilyato ceiling machine and high-end grilyato ceiling machine. The high-end open cell ceiling machine has a high-speed punching machine that can complete the punching of the entire production line at one time.

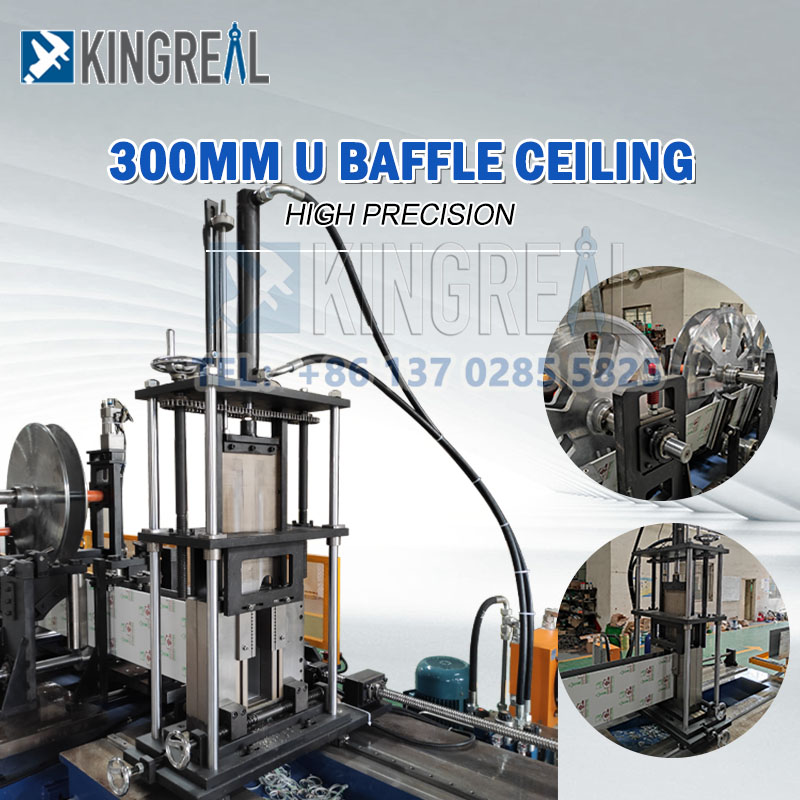

Details of U Baffle Machine

Advantages of Baffle Ceiling Machine

1.Three Models to Choose From: You can select the baffle ceiling machine from KINGREAL CEILING MACHINERY based on your production requirements for baffle ceilings. The 150mm baffle ceiling machine can produce baffle heights ranging from 35-150mm and widths from 30-100mm; the 200mm baffle ceiling machine can produce heights from 35-200mm and widths from 30-100mm; the 300mm baffle ceiling machine can produce heights from 35-300mm and widths from 50-100mm.

| 2. Customized New Design: The 300mm u baffle machine is custom-made by KINGREAL CEILING MACHINERY according to the actual production needs of our client, Douglas. KINGREAL CEILING MACHINERY can meet specific size requirements for baffle production. If you have new ideas or needs for baffle production, feel free to share your drawings with KINGREAL CEILING MACHINERY. After thorough communication, our designers will create a customized u baffle machine just for you. |  |

| 3. Ability to Produce Different Sizes: You won't need to frequently change baffle ceiling machines for producing different sizes of baffle ceilings. The KINGREAL CEILING MACHINERY u baffle machine can automatically adjust its width to produce various sizes of baffle ceilings. |  |

| 4. Follow-Shearing System for baffle ceiling machine: The cutting system utilizes a follow-cutting method. You only need to input the required cutting parameters, and the system can detect the length of the baffle material through sensors, controlling the cutting tool to operate at the right moment. Compared to stop-shearing, follow-shearing offers higher efficiency and precision since it can adjust while the material is in motion, reducing downtime and waste, thereby significantly improving your production efficiency. |  |

| 5. High Precision for baffle ceiling machine: The precision straightening machine features 10 upper rollers and 11 lower rollers, totaling 21 rollers. More rollers provide more uniform pressure and support, helping to straighten the material more effectively and reducing warping and deformation, thus enhancing product accuracy. |  |

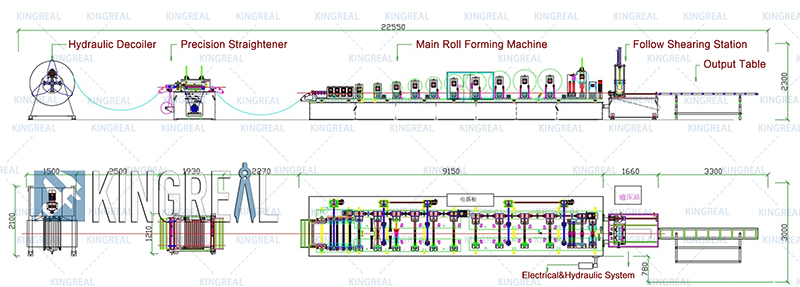

Working Process for Baffle Ceiling Machine

Hydraulic Decoiler -- Precision Straightener -- Main Roll Forming Machine -- Follow Shearing Station -- Output Table

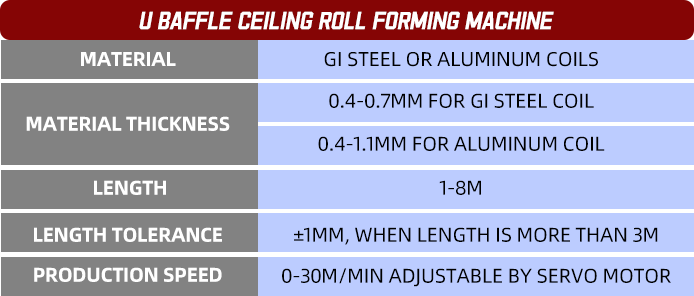

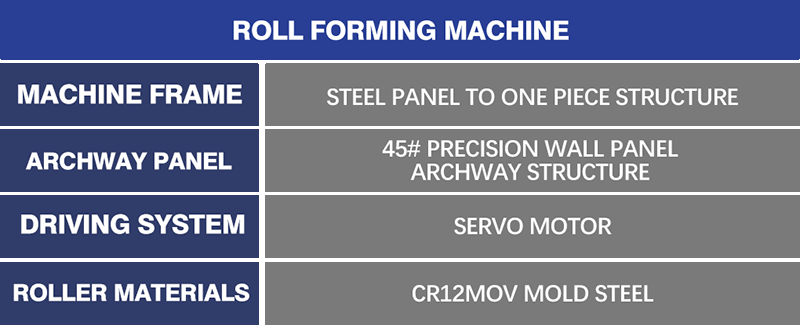

Parameter of Baffle Ceiling Machine

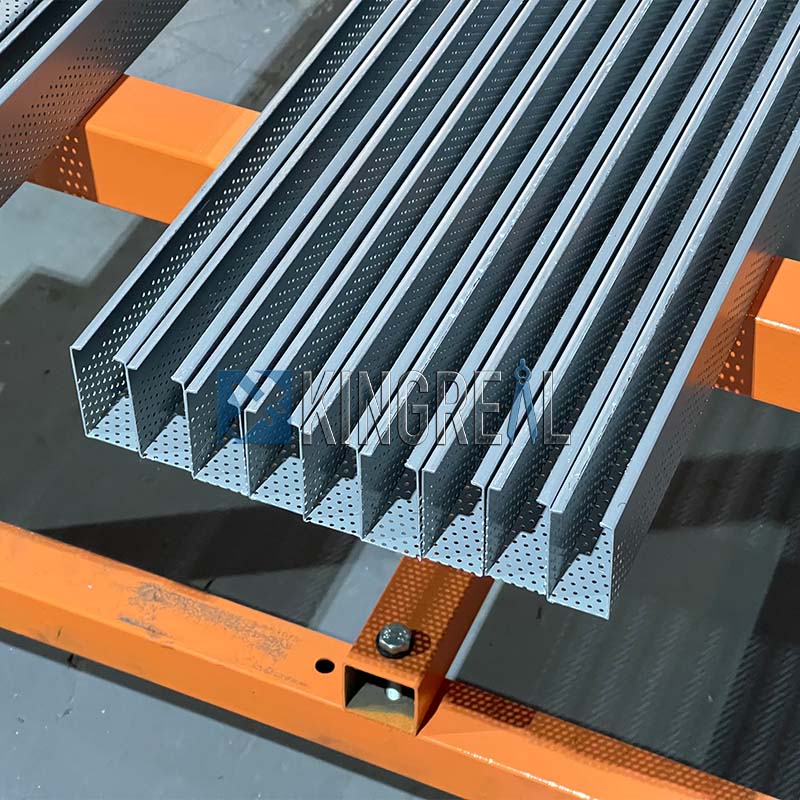

High Precision Baffle Ceilings

KINGREAL CEILING MACHINERY provides different types of baffle ceiling production lines, which can meet customers' needs to produce different types of baffle ceilings with a width of 25-100mm and a height of 75-300mm, such as U-shaped baffle ceilings, V-shaped baffle ceilings, etc.

Optional Equipment for Baffle Ceiling Machine

| Trolley for Baffle Ceiling Machine: The four-column direct-drive trolley uses hydraulic transmission, with a speed of 3m/min. It saves labor, improves production efficiency, and reduces safety hazards. |  |

| Baffle Carrier Roll Forming Machine: The production speed of the baffle ceiling carrier machine is 5-15m/min, with a finished product accuracy of ±1.0mm. It can produce U-shaped baffle ceiling carriers of corresponding sizes for installing baffle ceiling systems. |  |

More Videos About Baffle Ceiling Machine

Product Display

| Aluminum baffles offer an open view, ventilation, and breathability, making them suitable for concealed projects in densely populated public areas. They facilitate air circulation, exhaust, and heat dissipation while ensuring even light distribution, creating a spacious and bright environment. They are widely used in subways, high-speed train stations, bus stations, airports, large shopping malls, corridors, recreational areas, public restrooms, and the exteriors of buildings. |  |

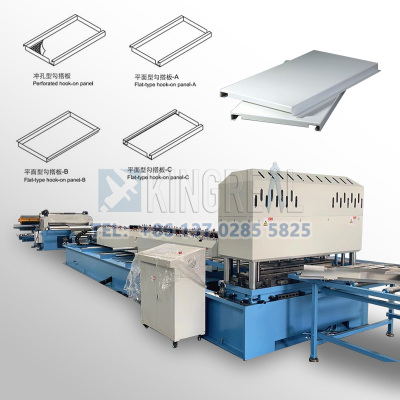

Details of Linear Strip Ceiling Machine

Advantages of Linear Strip Ceiling Machine

| 1. Production of Different Types of Linear Strip Ceilings: You can easily produce various types of linear strip ceilings with a singlelinear strip ceiling machine by simply changing the roller stations, cutting stations, and molds. This simple operation reduces line change and adjustment time, enhancing overall production efficiency. |  |

| 2. Automatic Width Adjustment: The automatic width-adjusting linear strip ceiling machine is KINGREAL CEILING MACHINERY's most distinctive roll forming machine. It can produce different sizes of metal strip ceilings within one machine, controlled by a rotary encoder and set via a touchscreen, allowing customers to flexibly choose their product dimensions. |  |

3. Three Models to Choose From: You can select a KINGREAL CEILING MACHINERY linear strip ceiling machine based on your needs. The adjustable width linear strip ceiling machine is suitable for producing different sizes of strip ceilings; the standard linear strip ceiling machine meets high-precision production demands; and the economical linear strip ceiling machine is designed for lightweight metal sheets, ideal for customers with lower speed and precision requirements.

Adjustable Width Linear Strip Ceiling Machine

Standard Linear Strip Ceiling Machine

Economical Linear Strip Ceiling Machine

| 4. Production of Perforated Linear Strip Ceilings: By adding a punching machine to the linear strip ceiling production line, you can produce ceilings with perforations without major reorganization of the production line, thus reducing implementation costs and complexity. |  |

Working Process of Linear Strip Ceiling Machine

Decoiler -- Straightener -- Main Roll Forming Machine -- Hydraulic Station -- Electric Control System -- Shearing Mechanism -- Receiving Table

Parameter of Linear Strip Ceiling Machine

High Precision Linear Strip Ceilings

KINGREAL CEILING MACHINERY's linear strip ceiling machine can produce C-shaped strip ceilings, G-shaped strip ceilings, U-shaped strip ceilings, and other different types of linear strip ceilings. If you have special type or parameter requirements, please send the drawings to KINGREAL CEILING MACHINERY engineers. After full communication, KINGREAL CEILING MACHINERY will provide a customized manufacturing plan for the linear strip ceiling production line.

Optional Equipment for Linear Strip Ceiling Machine

| Punching Station for Linear Strip Ceiling Machine: The linear strip ceiling machine combined with a punching station can produce finished products with perforations. The punching station is driven by a hydraulic system, capable of withstanding continuous and fast punching operations, ensuring stable perforation quality. The combination of the linear strip ceiling machine and the punching station not only enhances production capacity but also optimizes the entire production process, making the operation of the production line smoother and more efficient. |  |

| Linear Strip Carrier Machine: The maximum forming speed of the carrier machine is 20 m/min, allowing it to produce baffle ceiling cards of corresponding sizes for installing linear strip ceiling systems. |  |

More Videos About Linear Strip Ceiling Machine

Product Display

| Aluminum linear strip ceilings feature a sleek design, fire resistance, moisture resistance, cleanliness, environmental friendliness, and non-deformation, making them widely used in high-end office buildings, offices, corridors, airports, train stations, factories, hospitals, clubs, banks, shopping malls, exhibition halls, and more. |  |

Details of Open Cell Ceiling Machine

Advantages of Open Cell Ceiling Machine

| 1. Two Model Options for Open Cell Ceiling Machine: The KINGREAL CEILING MACHINERY standard open cell ceiling machine is equipped with a 16-ton punching machine that can punch one hole at a time. In comparison, the high-end model upgrades the punching station to a 63-ton station, allowing for simultaneous punching of multiple holes. This greatly improves production efficiency and product accuracy. |  |

| 2. Automatic Width Adjustment: The width of the KINGREAL CEILING MACHINERY metal open cell ceiling machine can be adjusted through a CNC system. The width, height, and length of the product can be automatically changed by the operator, allowing for the production of different sizes of grids. |  |

| 3. Compatibility: The open cell ceiling production line can simultaneously accommodate both iron and aluminum raw materials, enabling the production of two different types of grids with just one production line. This eliminates the inconvenience of adjusting the line for material changes. |  |

Working Process of Open Cell Ceiling Machine

Hydraulic Decoiler -- Precision Straightener -- Perforation Press -- Cut-to-length Press Machine -- Main Roll Forming Machine -- Product Table

Parameter of Open Cell Ceiling Machine

High Precision Open Cell Ceilings

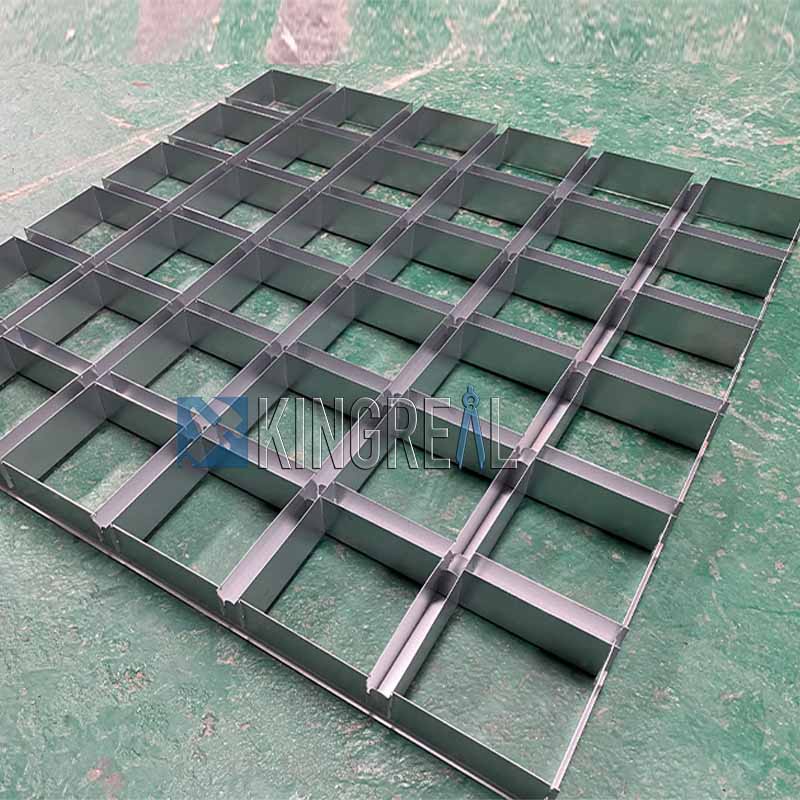

KINGREAL CEILING MACHINERY's open cell ceiling machine can be compatible with aluminum and iron metal raw materials to produce C-shaped, U-shaped, and pyramid-shaped open cell ceilings.

Optional Equipment for Open Cell Ceiling Machine

| Protective Shield for Open Cell Ceiling Machine: The open cell ceiling machine can be equipped with a protective shield to prevent dust, debris, and other external materials from entering the machine. This helps reduce equipment wear and extend its lifespan, while also effectively preventing operators from coming into contact with moving parts, thereby reducing the risk of accidental injury. |  |

More Videos About Open Cell Ceiling Machine

Product Display

| Open cell ceilings enhance spatial visibility and ventilation and are easy to install and dismantle. They are suitable for various applications, including offices, shopping malls, hotels, airports, train stations, exhibition centers, factories, and warehouses. |  |

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)