- Home

- >

- Products

- >

- Coil Processing Line

- >

Products Lists

1.What is a coil processing line?

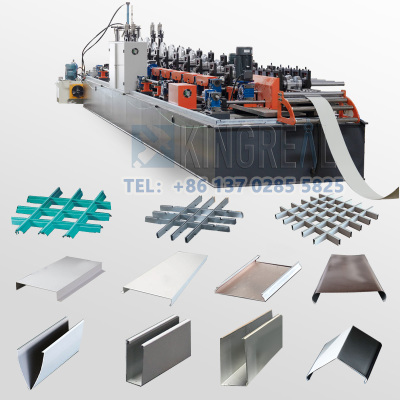

Coil processing line is a production equipment used to process metal coils (such as steel, aluminum, iron, copper, etc.) to meet the needs of subsequent processing or direct application. It is widely used in industries such as automobile manufacturing, home appliances, construction, aerospace, etc., and the products produced include body parts, home appliance housings, building materials, etc. By rationally configuring and optimizing these machines, coil processing lines can meet different production needs and improve production efficiency and product quality.

KINGREAL CEILING MACHINERY is a professional coil processing equipment manufacturer. The coil processing equipment that can be provided to customers includes sheet metal flattening machines, metal perforation lines, unwinder-straightener and feeder for sheet metal strip, metal slitting machines, metal cut to length lines, laser cutting machines, etc.

2.KINGREAL CEILING MACHINERY's innovative measures on coil processing lines

(1)Coil perforation line

The metal sheet perforation line punches metal sheets into metal perforated plates, and can punch out a variety of hole types and apertures according to customer needs. The common demand on the market is to punch holes in aluminum sheets and iron sheets, with common apertures of 1.8mm and 2.5mm. These KINGREAL CEILING MACHINERY metal perforated machines can meet all of these needs, and it is worth mentioning that the KINGREAL CEILING MACHINERY metal perforated machine can punch out micro perforated plates with an aperture of 1.0mm. This is a metal sheet perforation line customized for Greek customers. KINGREAL CEILING MACHINERY can make customized coil perforation line manufacturing solutions based on customer drawings.

KINGREAL CEILING MACHINERY engineers divide the metal perforation line into three categories according to the market situation —— coil perforation line with rewinding, metal sheet perforation line with cutting and metal ceiling perforation line.

To help customers who need to transport perforated sheets over long distances and manufacture perforated sheets into perforated screens, filters, baking trays, etc., KINGREAL CEILING MACHINERY engineers equipped the perforation line with a recoiler. To meet customers' requirements for specified lengths of perforated sheets, KINGREAL CEILING MACHINERY equipped the metal perforation line with a cutting station, which can accurately cut according to the customer's preset length. The perforated metal sheets can be made into perforated silencers, perforated wall panels, etc. For customers who need to make perfect perforated ceilings, KINGREAL CEILING MACHINERY has designed a metal ceiling perforated machine. It can be used in conjunction with KINGREAL CEILING MACHINERY's metal ceiling production line to produce perforated metal ceilings with an accuracy error within the range of ±0.1mm.

In addition, KINGREAL CEILING MACHINERY also provides detailed services. From the moment the customer finds us, KINGREAL CEILING MACHINERY has assigned a dedicated colleague to provide one-on-one docking services with the customer. Previously, KINGREAL CEILING MACHINERY's coil perforation line with rewinding was successfully manufactured. After rigorous testing by the staff, it was confirmed that the operation was stable and in line with the plan and the Brazilian customer's promise. After measuring and testing the perforated sheets to meet the customer's production requirements, they were packed and shipped to the Brazilian customer's factory. KINGREAL CEILING MACHINERY engineers also went to the Brazilian customer's factory to install the metal perforated making machine and teach the workers how to operate the steel perforated machine correctly. They also intimately explained to them the situations that may be encountered when using the perforated metal machine and how to solve them.

(2)Metal sheet straightener

Metal sheet leveling machine is a device that levels metal coils through rollers. KINGREAL CEILING MACHINERY's metal sheet straightening machine can level a variety of types, including metal sheets, metal parts, metal perforated mesh, metal rods, etc., with the advantages of easy cleaning and adjustable rollers. And corresponding steel plate flattening machines can be provided according to the actual production needs of customers.

Among them, the 4 high roller sheet metal leveling machine and the 6 high roller metal straightening machine are widely praised by customers. The steel plate flattening machine can be widely used in industries such as machinery, metallurgy, building materials, chemicals, electronics, electricity, light industry, as well as shipbuilding, locomotives, boilers, bridges, metal structure factories, etc.

(3)Unwinder-straightener and feeder for sheet metal strip

The punch press decoiler straightener feeder is an automated equipment that optimizes and combines multiple functions of unwinding, leveling, feeding, and punching. The working principle is to drive the feeding system through a servo motor to achieve the integration of the three functions of precise feeding, stamping and leveling of metal materials. This is achieved through high-precision servo motors and control systems to monitor and adjust the feeding speed and position in real time to ensure high precision and high efficiency of feeding.

Compared with the traditional split material rack leveling feeder production line, the 3 in 1 straightener feeder uncoiler occupies a smaller space, has a higher degree of automation, and is easier to operate. Most of its operations are completed on the touch screen.

3.About KINGREAL CEILING MACHINERY

(1) In the field of coil processing lines, KINGREAL CEILING MACHINERY has always been committed to technological innovation and product optimization, and has continuously expanded machine models to meet the needs of different industries. We actively expand the application field, from traditional metal processing to emerging high-end manufacturing, to ensure that we provide customers with the most cutting-edge solutions.

(2) KINGREAL CEILING MACHINERY's design and R&D team focuses on developing highly automated and user-friendly machines, striving to simplify operating procedures and improve production efficiency. Through the intelligent control system, operators can easily monitor and adjust production parameters, reduce customer training costs, and improve production flexibility and safety.

(3) In the process of deepening the coil processing industry, KINGREAL CEILING MACHINERY has accumulated rich experience and expertise to provide customers with tailor-made solutions. Whether it is for the processing needs of specific materials or complex production processes, we can provide comprehensive technical support to help customers achieve the goals of optimizing production, reducing costs and improving product quality.

Coil processing line is a production equipment used to process metal coils (such as steel, aluminum, iron, copper, etc.) to meet the needs of subsequent processing or direct application. It is widely used in industries such as automobile manufacturing, home appliances, construction, aerospace, etc., and the products produced include body parts, home appliance housings, building materials, etc. By rationally configuring and optimizing these machines, coil processing lines can meet different production needs and improve production efficiency and product quality.

KINGREAL CEILING MACHINERY is a professional coil processing equipment manufacturer. The coil processing equipment that can be provided to customers includes sheet metal flattening machines, metal perforation lines, unwinder-straightener and feeder for sheet metal strip, metal slitting machines, metal cut to length lines, laser cutting machines, etc.

2.KINGREAL CEILING MACHINERY's innovative measures on coil processing lines

(1)Coil perforation line

The metal sheet perforation line punches metal sheets into metal perforated plates, and can punch out a variety of hole types and apertures according to customer needs. The common demand on the market is to punch holes in aluminum sheets and iron sheets, with common apertures of 1.8mm and 2.5mm. These KINGREAL CEILING MACHINERY metal perforated machines can meet all of these needs, and it is worth mentioning that the KINGREAL CEILING MACHINERY metal perforated machine can punch out micro perforated plates with an aperture of 1.0mm. This is a metal sheet perforation line customized for Greek customers. KINGREAL CEILING MACHINERY can make customized coil perforation line manufacturing solutions based on customer drawings.

KINGREAL CEILING MACHINERY engineers divide the metal perforation line into three categories according to the market situation —— coil perforation line with rewinding, metal sheet perforation line with cutting and metal ceiling perforation line.

To help customers who need to transport perforated sheets over long distances and manufacture perforated sheets into perforated screens, filters, baking trays, etc., KINGREAL CEILING MACHINERY engineers equipped the perforation line with a recoiler. To meet customers' requirements for specified lengths of perforated sheets, KINGREAL CEILING MACHINERY equipped the metal perforation line with a cutting station, which can accurately cut according to the customer's preset length. The perforated metal sheets can be made into perforated silencers, perforated wall panels, etc. For customers who need to make perfect perforated ceilings, KINGREAL CEILING MACHINERY has designed a metal ceiling perforated machine. It can be used in conjunction with KINGREAL CEILING MACHINERY's metal ceiling production line to produce perforated metal ceilings with an accuracy error within the range of ±0.1mm.

In addition, KINGREAL CEILING MACHINERY also provides detailed services. From the moment the customer finds us, KINGREAL CEILING MACHINERY has assigned a dedicated colleague to provide one-on-one docking services with the customer. Previously, KINGREAL CEILING MACHINERY's coil perforation line with rewinding was successfully manufactured. After rigorous testing by the staff, it was confirmed that the operation was stable and in line with the plan and the Brazilian customer's promise. After measuring and testing the perforated sheets to meet the customer's production requirements, they were packed and shipped to the Brazilian customer's factory. KINGREAL CEILING MACHINERY engineers also went to the Brazilian customer's factory to install the metal perforated making machine and teach the workers how to operate the steel perforated machine correctly. They also intimately explained to them the situations that may be encountered when using the perforated metal machine and how to solve them.

(2)Metal sheet straightener

Metal sheet leveling machine is a device that levels metal coils through rollers. KINGREAL CEILING MACHINERY's metal sheet straightening machine can level a variety of types, including metal sheets, metal parts, metal perforated mesh, metal rods, etc., with the advantages of easy cleaning and adjustable rollers. And corresponding steel plate flattening machines can be provided according to the actual production needs of customers.

Among them, the 4 high roller sheet metal leveling machine and the 6 high roller metal straightening machine are widely praised by customers. The steel plate flattening machine can be widely used in industries such as machinery, metallurgy, building materials, chemicals, electronics, electricity, light industry, as well as shipbuilding, locomotives, boilers, bridges, metal structure factories, etc.

(3)Unwinder-straightener and feeder for sheet metal strip

The punch press decoiler straightener feeder is an automated equipment that optimizes and combines multiple functions of unwinding, leveling, feeding, and punching. The working principle is to drive the feeding system through a servo motor to achieve the integration of the three functions of precise feeding, stamping and leveling of metal materials. This is achieved through high-precision servo motors and control systems to monitor and adjust the feeding speed and position in real time to ensure high precision and high efficiency of feeding.

Compared with the traditional split material rack leveling feeder production line, the 3 in 1 straightener feeder uncoiler occupies a smaller space, has a higher degree of automation, and is easier to operate. Most of its operations are completed on the touch screen.

3.About KINGREAL CEILING MACHINERY

(1) In the field of coil processing lines, KINGREAL CEILING MACHINERY has always been committed to technological innovation and product optimization, and has continuously expanded machine models to meet the needs of different industries. We actively expand the application field, from traditional metal processing to emerging high-end manufacturing, to ensure that we provide customers with the most cutting-edge solutions.

(2) KINGREAL CEILING MACHINERY's design and R&D team focuses on developing highly automated and user-friendly machines, striving to simplify operating procedures and improve production efficiency. Through the intelligent control system, operators can easily monitor and adjust production parameters, reduce customer training costs, and improve production flexibility and safety.

(3) In the process of deepening the coil processing industry, KINGREAL CEILING MACHINERY has accumulated rich experience and expertise to provide customers with tailor-made solutions. Whether it is for the processing needs of specific materials or complex production processes, we can provide comprehensive technical support to help customers achieve the goals of optimizing production, reducing costs and improving product quality.

-

Catalogs:

-

![Perforated Metal Ceiling Panel Machine]()

Perforated Metal Ceiling Panel Machine

-

![Metal Sheet Perforation Production Line]()

Metal Sheet Perforation Production Line

-

![Steel Perforated Machine]()

Steel Perforated Machine

-

![Decoiler Straightener Feeder]()

Decoiler Straightener Feeder

-

![Metal Sheet Perforated Machine]()

Metal Sheet Perforated Machine

-

![Punch Press Decoiler Straightener Feeder]()

Punch Press Decoiler Straightener Feeder

-

![Perforated Metal Machine For Baguette Pan]()

Perforated Metal Machine For Baguette Pan

-

![NC Servo Feeder]()

NC Servo Feeder

-

![Perforated Machine For Metal Acoustic Wall Panel]()

Perforated Machine For Metal Acoustic Wall Panel

-

![High Precision Gantry Type Press Machine]()

High Precision Gantry Type Press Machine

-

![Metal Punching Machine For Metal Filter]()

Metal Punching Machine For Metal Filter

-

![Sheet Metal Decoilers]()

Sheet Metal Decoilers

Get the latest price? We'll respond as soon as possible(within 12 hours)