- Home

- >

- Products

- >

- Roll Forming Machine

- >

Products Lists

1/What Is Roll Forming Machine?

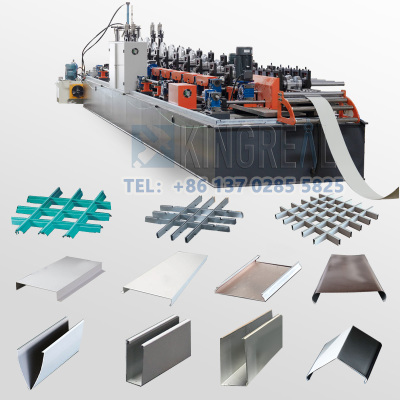

Roll forming machines are large-scale mechanical equipment designed to continuously bend metal sheets or strips through multiple rollers after unwinding metal coils to gradually form a specific cross-sectional shape. As one of the most common metal processing equipment, Roll forming machines are used in many industries, especially in the field of mass production of equal-section or variable-section profiles. Common applications include Metal Roofing Sheet Machine, warehousing series equipment, photovoltaic bracket equipment, and ceiling building materials related profile forming equipment. Products produced by roll forming are widely used in the construction and building materials industry, automobile manufacturing industry, industrial manufacturing industry, and home manufacturing industry.

KINGREAL CIELING MACHINERY is a team under KINGREAL MACHINERY that focuses on the field of ceiling equipment. In the field of roll forming machine equipment manufacturing, it focuses on providing customers with complete ceiling forming equipment solutions. Through various customized design and manufacturing of roll forming machines, customers can solve metal ceiling tile system, baffle ceiling tile system, linear strip ceiling tile system, open cell ceiling tile system, false ceiling channel system, and ventilation system equipment.

2/What Is The Manufacturing Feature Of Roll Forming Machine?

“Compared with other metal processing technologies, cold roll forming machines have many advantages and can process metal materials into finished products of various shapes without damaging them. Cold roll forming machines have higher processing accuracy and efficiency and meet the cold roll forming processing needs of various metal materials, including steel, iron, aluminum, copper and stainless steel raw materials. So what are the characteristics of KINGREAL CEILING MACHINERY in the field of ceiling forming machine manufacturing?”

1. KINGREAL CEILING MACHINERY Design When designing roll forming machine for customers, the rolls are made of C12MoV material, taking advantage of its wear resistance, and heat treatment is used to take advantage of the red hardness of C12MoV, and high-quality hardness is achieved after quenching. The cold roll forming machine frame is welded with Q345B steel plate, and the structural stiffness is increased by 40% after vibration mode optimization

2. The arc part of the cold roll forming machine track is the core part of the slide rail. The arc position after the first few press forming passes, when rolling the vertical edge in the next pass, the formed arc should be effectively protected by the upper and lower rolls or cross wheels.

3.The roll forming machine adopts servo drive technology, and is equipped with independent servo motors in key positions such as the variable cross-section area to achieve dynamic adjustment of the roller lateral ±0.05mm, supporting the production of variable curvature/variable cross-section products.

3/ Case Of Roll Forming Machine In Suspended Ceiling Field

1, Metal Ceiling Tile Solution

KINGREAL CEILING MACHINERY can supply whole solution for the metal ceiling tile system, which including metal ceiling tile production line, metal ceiling carrier roll forming machine, ceiling t bar roll forming machine and other parts production equipment required for installing suspended ceilings.

KINGREAL CEILING MACHINERY is not only a manufacturer of metal ceiling equipment, but also focuses on helping customers achieve long-term production benefits. KINGREAL CIELING MACHINERY provides customers with suitable production solutions by analyzing the needs and characteristics of the local market for ceiling building materials and the actual positioning and production needs of the customer's factory.

For example, in 2025, KINGREAL CEILING MACHINERY provides open cell ceiling roll forming and ceiling t bar roll forming machines for Uzbek customers. The main tee and cross tee produced by the ceiling t bar machine are used to install open cell ceiling tiles to achieve a complete open cell ceiling system to meet the needs of the local market in Uzbekistan and create production benefits for customers.

In 2024, KINGREAL CIELING MACHINERY helped Indian customers complete the design, production and manufacturing of four Ceiling T Bar Machines, and tested samples sent by customers, designed forming machines and punching machines, etc., to match lay in metal ceiling tile products, in line with the actual production needs of customer factories.

For baffle ceiling machine and linear strip ceiling machine, KINGREAL CEILING MACHINERY can provide metal ceiling carrier roll forming machine to help customers solve the production needs of ceiling installation carrier.

2, False Ceiling Channel System Solution

Solution 1: It consists of U-shaped, wall angle and omega channel false ceiling channel. As the main channel, the U-shaped channel is arranged along the long side of the room, connected to the ceiling through hanging pieces, bearing the weight of the whole ceiling and building the main supporting structure. L-shaped channel is used in the corners of ceiling, such as corners, doors and windows, which plays a role in closing and fixing, making the edges of ceiling neat and beautiful and improving stability. As the cross tee, the hat-shaped channel is installed perpendicular to the main tee, which is used to fix decorative panels such as gypsum board to ensure smooth installation and prevent deformation.

Solution 2: This ceiling system based on CD and UD. CD as the main load-bearing keel and UD as the facing keel, and they are combined together to build a stable keel frame. This scheme is suitable for large-area or high-load ceiling systems, which can effectively disperse the weight of the ceiling and greatly improve the strength and stability of the overall structure.

3,False Ceiling Channel Machine

KINGREAL CEILING MACHINERY false ceiling channel machine can produce various types of ceiling channels with different sizes, including U-shaped, L-shaped, hat-shaped, CD and UD, and carefully create two practical ceiling system solutions for customers. Moreover, KINGREAL CEILING MACHINERY has been innovating in the design and development of false ceiling channel machine. In view of customers' pursuit of production efficiency and convenience, the false ceiling channel machine equipped with auto packaging machine was successfully introduced, which realized the seamless connection between production and packaging. In order to further optimize the utilization of resources, we have also developed a multi-specification false ceiling channel machine, which can produce L-shaped, U-shaped and hat-shaped profiles through one production line.

In terms of service, KINGREAL CEILING MACHINERY always adheres to the customer-centric concept. For example, Saudi Arabian customers are faced with the problem that the machine can't operate normally due to high temperature weather. We responded quickly and put forward a targeted solution for adding cooling equipment to the motor, which effectively guaranteed the stable operation of false ceiling channel machine in high temperature environment and won high praise from customers.

4, Complete Ventilation System

In the field of ventilation of modern buildings, the products produced by the series of advanced mechanical equipment provided by KINGREAL CEILING MACHINERY, such as vcd damper machine, TDC flange machine and HVAC Rectangular Damper Blade Machine, cooperate with each other to carefully create a comprehensive and efficient ventilation system solution for customers, aiming to create a comfortable and healthy air environment for various building spaces. Among them, the TDC flange machine designed by KINGREAL CEILING MACHINERY can provide different types of flanges according to actual conditions - vcd damper with flange inside, vcd damper with flange outside and vcd damper frame without flange.

Roll forming machines are large-scale mechanical equipment designed to continuously bend metal sheets or strips through multiple rollers after unwinding metal coils to gradually form a specific cross-sectional shape. As one of the most common metal processing equipment, Roll forming machines are used in many industries, especially in the field of mass production of equal-section or variable-section profiles. Common applications include Metal Roofing Sheet Machine, warehousing series equipment, photovoltaic bracket equipment, and ceiling building materials related profile forming equipment. Products produced by roll forming are widely used in the construction and building materials industry, automobile manufacturing industry, industrial manufacturing industry, and home manufacturing industry.

KINGREAL CIELING MACHINERY is a team under KINGREAL MACHINERY that focuses on the field of ceiling equipment. In the field of roll forming machine equipment manufacturing, it focuses on providing customers with complete ceiling forming equipment solutions. Through various customized design and manufacturing of roll forming machines, customers can solve metal ceiling tile system, baffle ceiling tile system, linear strip ceiling tile system, open cell ceiling tile system, false ceiling channel system, and ventilation system equipment.

2/What Is The Manufacturing Feature Of Roll Forming Machine?

“Compared with other metal processing technologies, cold roll forming machines have many advantages and can process metal materials into finished products of various shapes without damaging them. Cold roll forming machines have higher processing accuracy and efficiency and meet the cold roll forming processing needs of various metal materials, including steel, iron, aluminum, copper and stainless steel raw materials. So what are the characteristics of KINGREAL CEILING MACHINERY in the field of ceiling forming machine manufacturing?”

1. KINGREAL CEILING MACHINERY Design When designing roll forming machine for customers, the rolls are made of C12MoV material, taking advantage of its wear resistance, and heat treatment is used to take advantage of the red hardness of C12MoV, and high-quality hardness is achieved after quenching. The cold roll forming machine frame is welded with Q345B steel plate, and the structural stiffness is increased by 40% after vibration mode optimization

2. The arc part of the cold roll forming machine track is the core part of the slide rail. The arc position after the first few press forming passes, when rolling the vertical edge in the next pass, the formed arc should be effectively protected by the upper and lower rolls or cross wheels.

3.The roll forming machine adopts servo drive technology, and is equipped with independent servo motors in key positions such as the variable cross-section area to achieve dynamic adjustment of the roller lateral ±0.05mm, supporting the production of variable curvature/variable cross-section products.

3/ Case Of Roll Forming Machine In Suspended Ceiling Field

1, Metal Ceiling Tile Solution

KINGREAL CEILING MACHINERY can supply whole solution for the metal ceiling tile system, which including metal ceiling tile production line, metal ceiling carrier roll forming machine, ceiling t bar roll forming machine and other parts production equipment required for installing suspended ceilings.

KINGREAL CEILING MACHINERY is not only a manufacturer of metal ceiling equipment, but also focuses on helping customers achieve long-term production benefits. KINGREAL CIELING MACHINERY provides customers with suitable production solutions by analyzing the needs and characteristics of the local market for ceiling building materials and the actual positioning and production needs of the customer's factory.

For example, in 2025, KINGREAL CEILING MACHINERY provides open cell ceiling roll forming and ceiling t bar roll forming machines for Uzbek customers. The main tee and cross tee produced by the ceiling t bar machine are used to install open cell ceiling tiles to achieve a complete open cell ceiling system to meet the needs of the local market in Uzbekistan and create production benefits for customers.

In 2024, KINGREAL CIELING MACHINERY helped Indian customers complete the design, production and manufacturing of four Ceiling T Bar Machines, and tested samples sent by customers, designed forming machines and punching machines, etc., to match lay in metal ceiling tile products, in line with the actual production needs of customer factories.

For baffle ceiling machine and linear strip ceiling machine, KINGREAL CEILING MACHINERY can provide metal ceiling carrier roll forming machine to help customers solve the production needs of ceiling installation carrier.

2, False Ceiling Channel System Solution

Solution 1: It consists of U-shaped, wall angle and omega channel false ceiling channel. As the main channel, the U-shaped channel is arranged along the long side of the room, connected to the ceiling through hanging pieces, bearing the weight of the whole ceiling and building the main supporting structure. L-shaped channel is used in the corners of ceiling, such as corners, doors and windows, which plays a role in closing and fixing, making the edges of ceiling neat and beautiful and improving stability. As the cross tee, the hat-shaped channel is installed perpendicular to the main tee, which is used to fix decorative panels such as gypsum board to ensure smooth installation and prevent deformation.

Solution 2: This ceiling system based on CD and UD. CD as the main load-bearing keel and UD as the facing keel, and they are combined together to build a stable keel frame. This scheme is suitable for large-area or high-load ceiling systems, which can effectively disperse the weight of the ceiling and greatly improve the strength and stability of the overall structure.

3,False Ceiling Channel Machine

KINGREAL CEILING MACHINERY false ceiling channel machine can produce various types of ceiling channels with different sizes, including U-shaped, L-shaped, hat-shaped, CD and UD, and carefully create two practical ceiling system solutions for customers. Moreover, KINGREAL CEILING MACHINERY has been innovating in the design and development of false ceiling channel machine. In view of customers' pursuit of production efficiency and convenience, the false ceiling channel machine equipped with auto packaging machine was successfully introduced, which realized the seamless connection between production and packaging. In order to further optimize the utilization of resources, we have also developed a multi-specification false ceiling channel machine, which can produce L-shaped, U-shaped and hat-shaped profiles through one production line.

In terms of service, KINGREAL CEILING MACHINERY always adheres to the customer-centric concept. For example, Saudi Arabian customers are faced with the problem that the machine can't operate normally due to high temperature weather. We responded quickly and put forward a targeted solution for adding cooling equipment to the motor, which effectively guaranteed the stable operation of false ceiling channel machine in high temperature environment and won high praise from customers.

4, Complete Ventilation System

In the field of ventilation of modern buildings, the products produced by the series of advanced mechanical equipment provided by KINGREAL CEILING MACHINERY, such as vcd damper machine, TDC flange machine and HVAC Rectangular Damper Blade Machine, cooperate with each other to carefully create a comprehensive and efficient ventilation system solution for customers, aiming to create a comfortable and healthy air environment for various building spaces. Among them, the TDC flange machine designed by KINGREAL CEILING MACHINERY can provide different types of flanges according to actual conditions - vcd damper with flange inside, vcd damper with flange outside and vcd damper frame without flange.

-

![Ceiling Channel Roll Forming Machine]()

Ceiling Channel Roll Forming Machine

-

![Metal Ceiling T Bar Making Machine]()

Metal Ceiling T Bar Making Machine

-

![Automatic Tee Bar Grid Roll Forming Machine]()

Automatic Tee Bar Grid Roll Forming Machine

-

![Black Line Ceiling T Bar Machine]()

Black Line Ceiling T Bar Machine

-

![Silhouette T Grid Roll Forming Machine]()

Silhouette T Grid Roll Forming Machine

-

![Linear Metal Ceiling Carrier Making Machine]()

Linear Metal Ceiling Carrier Making Machine

-

![Volume Control Damper Making Machine]()

Volume Control Damper Making Machine

-

![Fire Damper Frame Machine]()

Fire Damper Frame Machine

-

![Spring Tee CLIP IN Carrier Roll Forming Machine]()

Spring Tee CLIP IN Carrier Roll Forming Machine

-

![HVAC Spiral Duct Making Machine]()

HVAC Spiral Duct Making Machine

-

![A-Type Carrier Roll Forming Machine]()

A-Type Carrier Roll Forming Machine

-

![Omega Profile Roll Forming Machine]()

Omega Profile Roll Forming Machine

Get the latest price? We'll respond as soon as possible(within 12 hours)