Metal Ceiling T Bar Making Machine

KINGREAL CEILING MACHINERY can offer a full automatic equipment - a Metal Ceiling T Bar Roll Forming Machine, which can make high quality t bar grids for hanging lay-in ceiling tile.

- KINGREAL CEILING MACHINERY

- China

- 90 Days

- 9999

Details

Video About Metal Ceiling T Grid Machine

Related Project

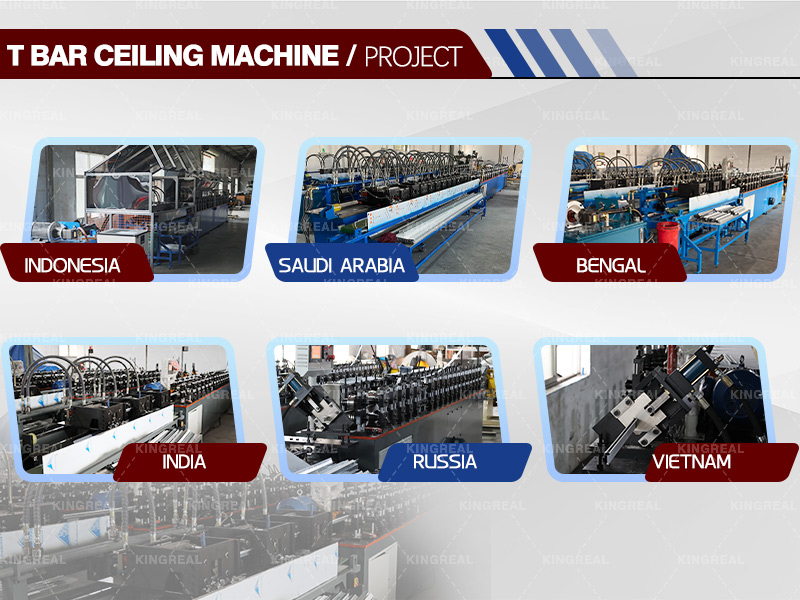

Ceiling t bar making machine is a featured machine of KINGREAL CEILING MACHINERY. So far, it has had friendly cooperation with customers from Indonesia, Saudi Arabia, Bangladesh, India, Russia, Vietnam and other countries. KINGREAL CEILING MACHINERY has rich project case support. KINGREAL CEILING MACHINERY engineers have visited customer factories in various countries to provide machine installation and operation guidance services for customers, and understand the different requirements of various countries for ceiling t bar machine parameters.

Description of Metal Ceiling T Bar Making Machine

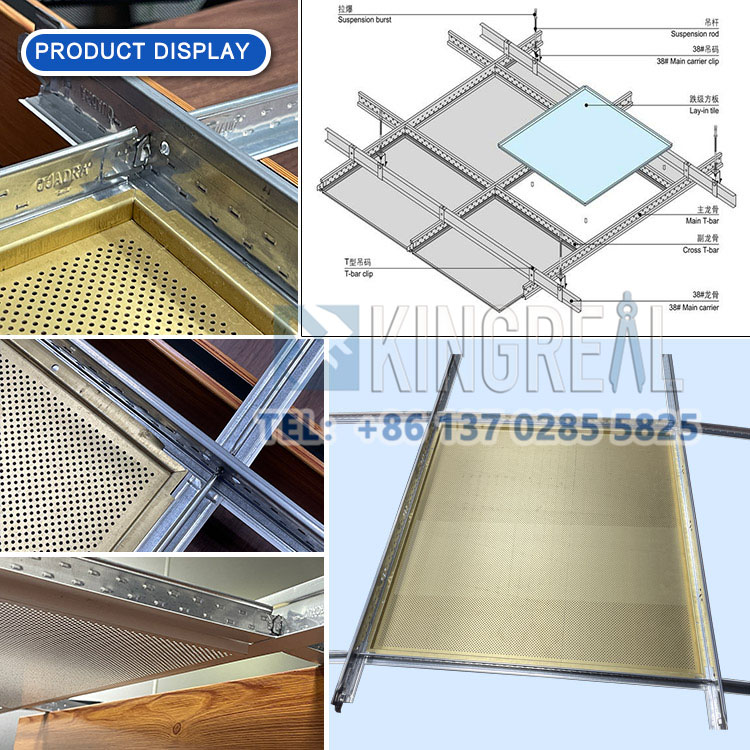

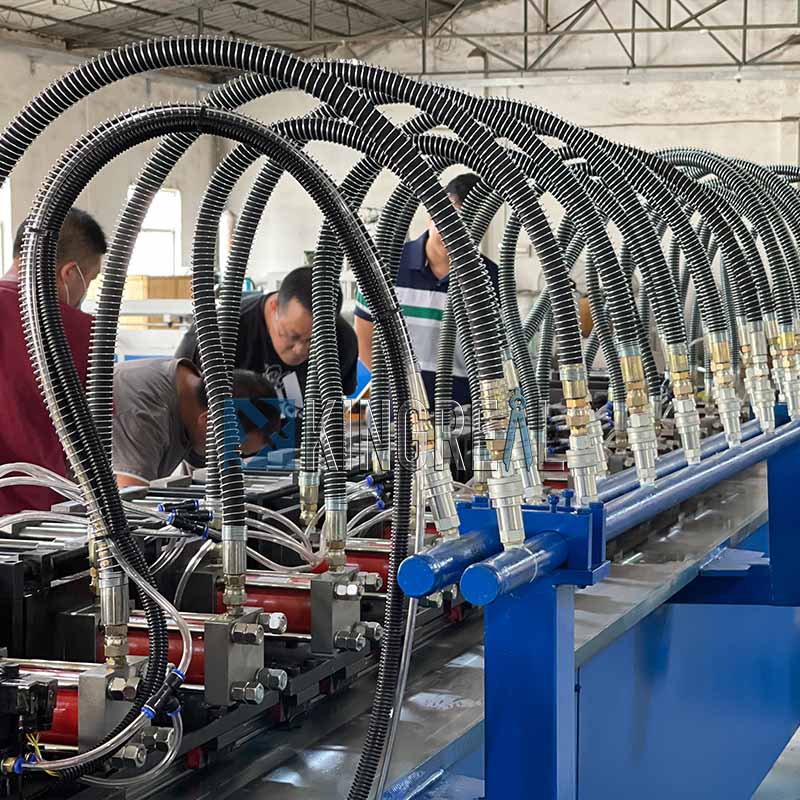

KINGREAL CEILING MACHINERY metal cross tee machine is an efficient equipment designed for the production of T-shaped frames for ceiling. The equipment is mainly composed of a number of high-precision components such as decoiler, main roll forming machine, punching press and automatic cutting station, which ensures the high efficiency, stability and accuracy of the production process.

One of the core components of KINGREAL CEILING MACHINERY ceiling t bar machine is the main roll forming machine, which can automatically form steel strips into t bar ceilings of various sizes and lengths according to customer requirements. This process not only improves production efficiency, but also guarantees the consistency and high-quality appearance of the molded product.

As a professional supplier of ceiling manufacturing equipment, KINGREAL CEILING MACHINERY is committed to providing customers with tailor-made solutions. Whether it is T-grid or overall ceiling production, KINGREAL CEILING MACHINERY can provide comprehensive support from equipment selection to production line layout, from technical training to after-sales service. KINGREAL CEILING MACHINERY's goal is to help customers improve production efficiency, reduce operating costs and improve product quality through advanced equipment and professional services.

Different Types of Ceiling T Bar Description

Main t bar grid making machine:

KINGREAL CEILING MACHINERY main t bar grid production line is composed of decoilers, main roll forming machine, Automatic hydraulic cutting off station, hydraulic cooling station and electric control system, etc.

- Main Tee bar size:H38*24mm, H32*24mm

- Length: 3600mm

- Thickness:0.20-0.40mm

Cross ceiling t bar making machine:

KINGREAL CEILING MACHINERY cross ceiling t bar production line is composed of decoilers, main roll forming machine, Automatic hydraulic cutting off station, hydraulic cooling station and electric control system, etc.

- Cross Tee:H26*24mm, H24*23mm

- Length: 1200mm, 600mm

- Thickness:0.20-0.40mm

Features of Steel T Bar Machine

| Highly precise ①Full automatic with high speed: 30m/min; ②The total length tolerance is ±0.2mm. Tolerance of hole spacing ±0.1mm. |  |

| Efficient punching system Most systems are equipped with advanced automated controls that allow the entire cutting and punching process to be completed without human intervention. It is designed for high-speed production, can complete a large number of cutting and punching tasks in a short time, with high-precision cutting, punching functions, to ensure the keel size, hole position accurate. |

Specification

| Raw materials | Galvanized Steel, Pre-painted Galvanized Steel |

| Material thickness: Galvanized Steel | 0.25-0.35mm; Pre-painted Galvanized Steel: 0.3-0.4mm |

| Finished T bar size | As per customer's requirement |

| Maximum forming speed | 20-30 m / min |

Complete Solution

Ceiling t bar can be used with lay-in ceiling to form a complete suspended ceiling system. In addition, KINGREAL CEILING MACHINERY can also provide customers with metal ceiling production lines of various sizes and types, without the need for customers to connect with multiple different suppliers, and can also ensure that the two machines can work perfectly together.

More Information About CEILING T Grid Machine

1.What's the purpose of ceiling t bar machine?

2.What are the advantages of ceiling t grid machine?

3.Ceiling t bar machine maintenance guide

4.How to use a t bar ceiling machine?

5.Local After-sales Service -- T Bar Ceiling Machine

Different Types of Metal Ceiling T Bar Making Machine

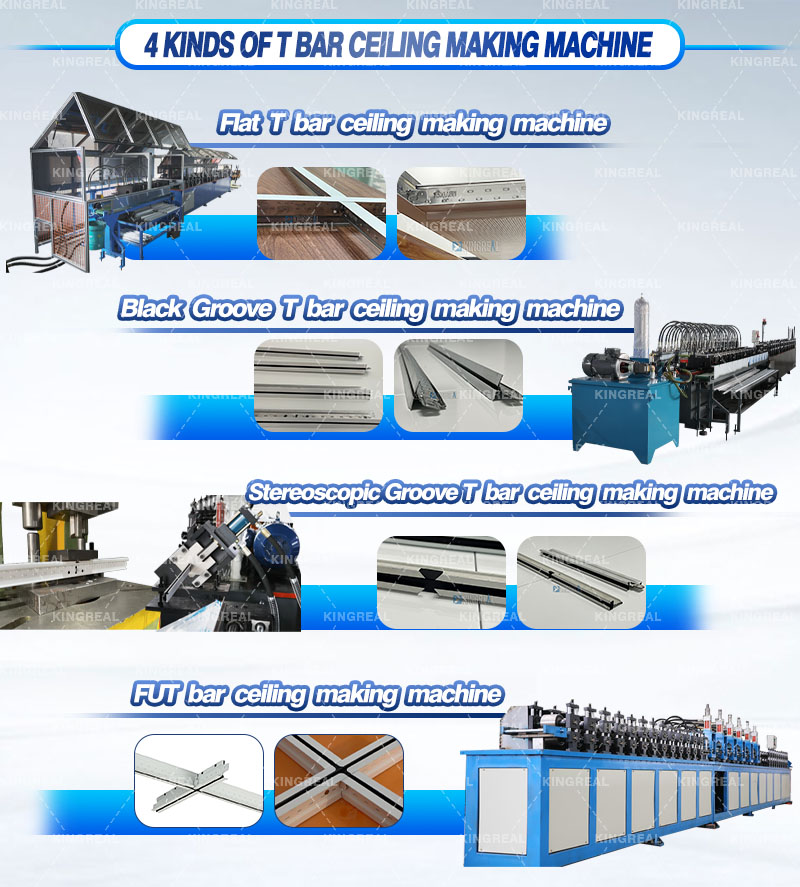

KINGREAL CEILING MACHINERY can provide different types of ceiling t grid machines, including the most popular flat t bar ceiling machines, black groove t bar machines, stereoscopic groove t bar ceiling machines, and FUT ceiling t bar machines. KINGREAL CEILING MACHINERY has corresponding ceiling t grid machines to provide production. If you have special needs, you can also communicate with the engineer, and KINGREAL CEILING MACHINERY will provide a customized ceiling t bar machine manufacturing plan.

Quality Insurance

KINGREAL CEILING MACHINERY has passed ISO9000 certification and has the ability of ISO9000 quality system management.

After you order, KINGREAL CEILING MACHINERY technical team will test the machine in an effort to ensure every mechanical and electrical part is in perfect condition.

Customer Visit

It is such a delight to have friends coming from afar. KINGREAL CEILING MACHINERY warmly welcomes customers to visit KINGREAL CEILING MACHINERY factory and communicate with us!

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)