Silhouette T Grid Roll Forming Machine

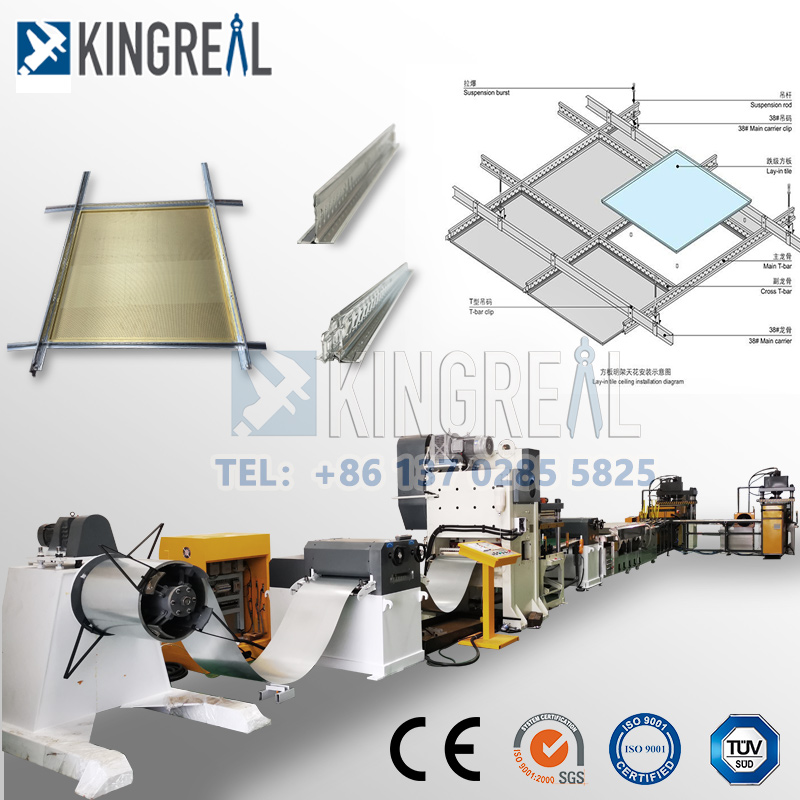

KINGREAL CEILING MACHINERY Silhouette T Grid Roll Forming Machine is design for produce the metal ceiling carrier keel to used in lay-in ceiling. As a professional sheet-forming equipment manufacturer, KINGREAL CEILING MACHINERY has experienced factory division and professional production workshop, which can provide customers with high quality products.

Details

Video Display About Silhouette T Grid Making Machine

KINGREAL CEILING MACHINERY Successful Projects in Global

Description Of Ceiling T Grid Machine

KINGREAL CEILING MACHINERY Silhouette T Grid Roll Forming Machine including 3 machines: One for main tee bars, one for cross tees, and one for wall angles. All these 3 machines are roll forming type. The standard ceiling T bar roll forming machine is consists of 2 Decoilers, Main Roll Forming Machine, Hydraulic Cutting System, Product Table, Electrical and Hydraulic System.

KINGREAL CEILING MACHINERY uses sustainable material to build our machine, like CR12MOV steel for rollers, HRC55-58 axis. So that KINGREAL CEILING MACHINERY's machine will work for a long time. Also, the component of hydraulic system is from famous brand like YASKAWA.

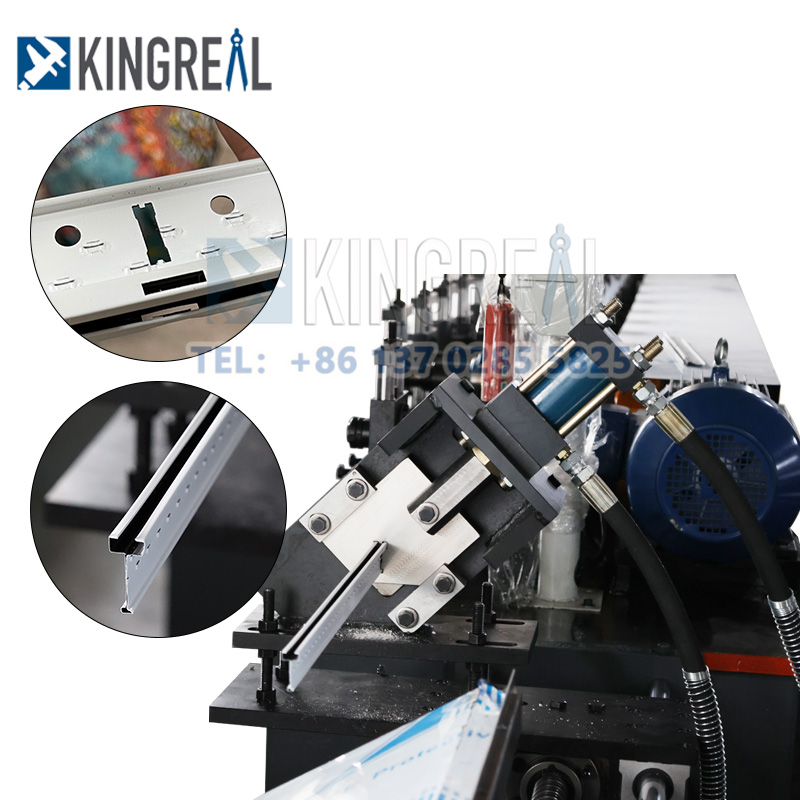

New Design For Silhouette T Bar Metal Ceiling Machine

Based on the unique characteristics of this silhouette T grid product, KINGREAL CEILING MACHINERY maintains custom designed production equipment that is distinct from the standard model.

KINGREAL CEILING MACHINERY uses a full automatic forming line with semi-auto punching machine to produce the silhouette T grid product. The whole production line is powered by worm speed reducers. These reducers are more often used for high-speed drywall studs and tracks machines. They can let the production line speed to be controlled well, and provides 20m/min regular speed, 30m/min maximum.

Technical Specification

| Machine Name | Silhouette T Grid Roll Forming Machine |

| Products Name | Main T-bar, Cross T-bar, type: silhouette T |

| Products sizes | T15; T24 |

| Automation | Manual Operation/Full-Automatic Production with PLC |

| Certificate | CE certificate, ISO 9001 certificate |

| Machine Power | 380V 50HZ or according with customers' request |

| Speed | 30M/Min |

| Main Features | Equipped with air cooling system, Famous brand hydraulic system, light curtain safety protection |

Features Of Ceiling T Grid Machine

The whole production line is powered by worm speed reducers. These reducers are more often used for high-speed drywall studs and tracks machines. They can let the production line speed to be controlled well, and provides 20m/min regular speed, 30m/min maximum. |  |

| 2. KINGREAL CEILING MACHINERY machine frame is welded by steel panel to one-piece structure. Then one 30mm thickness panel will be put on the frame after fine processed by the Plano miller. This will ensure the accuracy basic size. Also, it will increase the machine strength to reduce the deformation and ensure the long-life time operation. |

3. KINGREAL CEILING MACHINERY uses high-quality imported electrical appliances, such as Japanese Yaskawa NC servo feeder, PLC from FATEK, MCGS touch screens, which can ensure stable and continuous work of KINGREAL CEILING MACHINERY's machines. |  |

Different T Bar Production Solution

Silhouette T Grid For Lay-In Ceiling

Lay-In ceiling is a common ceiling design, also known as a "suspended ceiling". It is often removable, making it easier to repair and replace. Lay-in ceilings are popular in the building materials market because they conceal electrical wiring, plumbing and other ceiling fixtures, providing a cleaner and more aesthetically pleasing appearance.

Also T Grid are increasingly in demand as an integral part of ceiling mount systems.

KINGREAL CEILING MACHINERY as a professional sheet-forming equipment manufacturer in China, can provide complete Lay-in Suspended Ceiling Machine Solution and other roll forming machine, welcome to contact us.

Other Featuring Machines in KINGREAL CEILING MACHINERY

KINGREAL CEILING MACHINERY Factory

To integrate R&D, KINGREAL CEILING MACHINERY has established our own factory, located in Foshan, Guangdong. In addition to maintaining close contact online, many of KINGREAL CEILING MACHINERY's customers also choose to visit KINGREAL factory to observe the production of machines and communicate with us face to face. KINGREAL CEILING MACHINERY is looking forward to reaching long-term and stable relationships with customers around the world with KINGREAL CEILING MACHINERY's professional capability and consistent level of service!

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)