Quality Assurance

After the machine is assembled, KINGREAL CEILING MACHINERY will conduct a series of rigorous tests to ensure that each device meets high quality standards before leaving the factory. These testing processes are divided into multiple rounds and cover all aspects of the machine.

(1) Functional testing

Functional testing is the first step in the testing process. First, a static functional test is carried out to check the working status and performance of each component. Subsequently, a dynamic test is carried out to monitor the stability, noise, vibration and other parameters of the machine's operation while the machine is running to ensure that the equipment can operate normally in actual applications. Through these tests, the staff can detect potential problems in time and ensure the reliability of the machine.

(2) Safety testing

KINGREAL CEILING MACHINERY attaches great importance to the safety of the machine. At this stage, the staff conducts a comprehensive inspection of all safety protection devices, including emergency stop buttons, guards, etc., to ensure their normal operation to prevent accidents during operation. At the same time, the electrical system will be carefully inspected, including grounding, insulation and overload protection, to ensure the electrical safety of the machine during use. This series of safety tests is an important part of ensuring the safety of operators.

(3) Performance evaluation

Next, the staff of KINGREAL CEILING MACHINERY will conduct a comprehensive evaluation of the performance of the machine. This evaluation is mainly divided into two parts:

1. Efficiency test: Evaluate the working efficiency of the machine, including production speed and energy consumption, to ensure that it meets the design indicators.

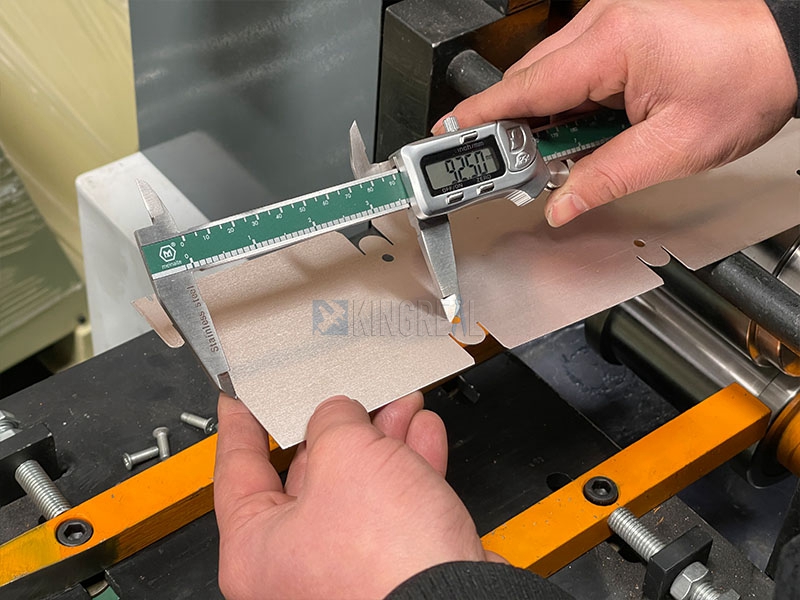

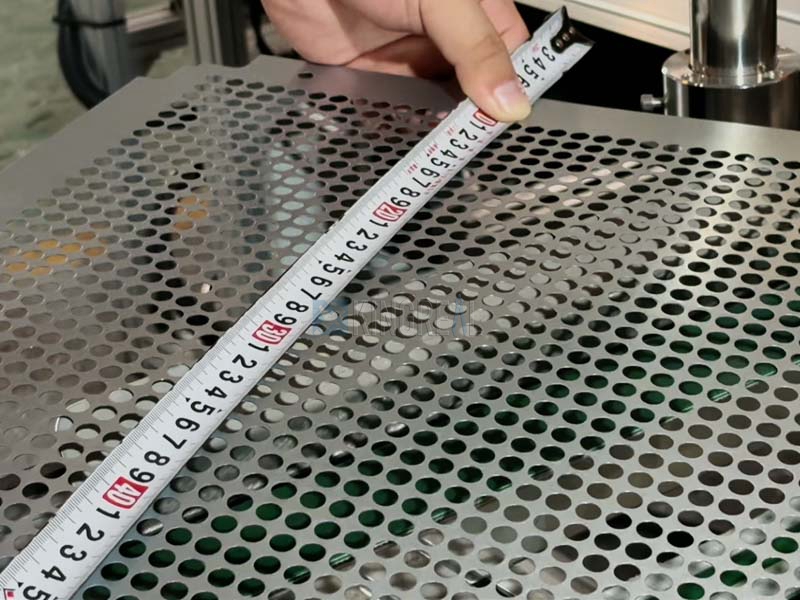

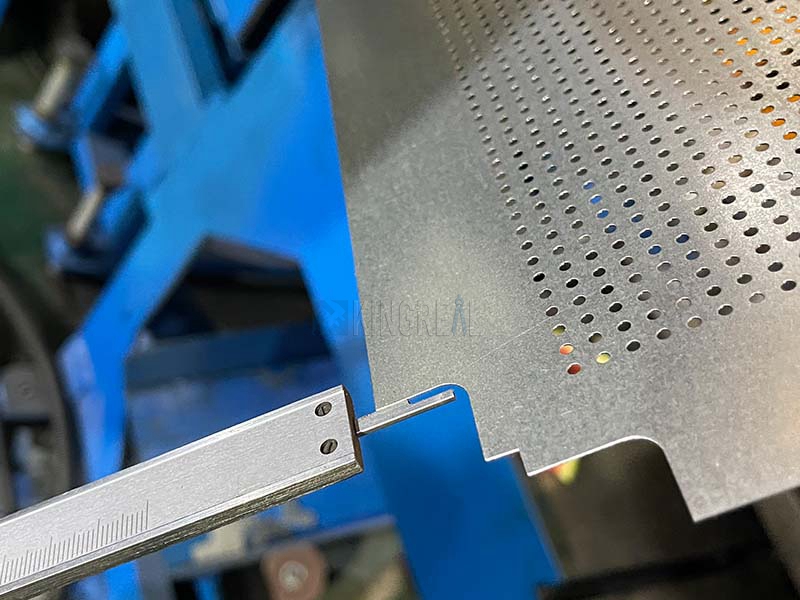

2. Quality test: Perform quality inspection on the finished products produced by the machine, check the accuracy of the finished products, whether there are burrs on the surface, whether the hole spacing is consistent, etc., to ensure that it meets the customer's standards and requirements.

(4) Final inspection

After all functional, performance and safety tests are completed, the staff of KINGREAL CEILING MACHINERY will conduct a final inspection of the entire machine. This includes multiple aspects such as appearance, function, safety and performance to ensure that all test items meet the standards. In addition, the test results will be recorded in detail, including certificates of conformity, test reports and inspection records, for subsequent tracking and customer review. At the same time, we will send videos and photos of the day's inspection process to customers to increase transparency and trust.

The machine will only be shipped to the customer's factory after all tests are completed and qualified. If any problems are found during the inspection process, the staff will immediately debug and retest to ensure that the equipment is in the best condition before delivery. Through this series of strict quality inspection processes, KINGREAL CEILING MACHINERY is committed to providing high-reliability and high-performance machinery and equipment to meet customer needs.

Get the latest price? We'll respond as soon as possible(within 12 hours)