- Home

- >

- Factory View

- >

Factory View

KINGREAL CEILING MACHINERY Comprehensive Manufacturing Solutions

KINGREAL CEILING MACHINERY is a professional sheet metal processing manufacturer, with its factory located in Foshan, Guangdong, China. We focus on providing high-quality machinery and equipment, and our main products can be divided into three major sections:

Metal ceiling tile production line

KINGREAL CEILING MACHINERY provides a variety of metal ceiling tile production lines with aluminum and iron as metal raw materials to meet the different production needs of customers. KINGREAL CEILING MACHINERY can produce the following sizes and types of metal ceiling tiles:

The metal ceiling machine is produced by leveling, punching and cutting metal raw materials. In order to maximize the production efficiency for customers, KINGREAL CEILING MACHINERY can equip customers with feeding trolleys, notching and shearing presses of different tonnages and different types of auto bending forming presses. KINGREAL CEILING MACHINERY engineers will provide customized metal ceiling tile production line manufacturing solutions based on the customer's specific parameters (different thickness, width range, production capacity and different raw materials).

- Size: 300x300mm, 600x600mm, 600x1200mm, etc.

- Type: Clip-in metal ceiling panel, Lay-in metal ceiling panel, Lay-on metal ceiling panel, Tegular metal ceiling panel, etc.

- Other types of metal ceiling boards: Fabric ceiling tiles, perforated metal ceiling tiles, plain metal ceiling tiles, powder-coated metal ceiling tiles, etc.

KINGREAL CEILING MACHINERY's featured metal ceiling tile production lines include:

|  |  |  |

| - 300x300mm metal ceiling production line | - 600x600mm metal ceiling production line | - 600x1200mm metal ceiling production line | - Semi-automatic metal ceiling production line |

Metal sheet perforation line

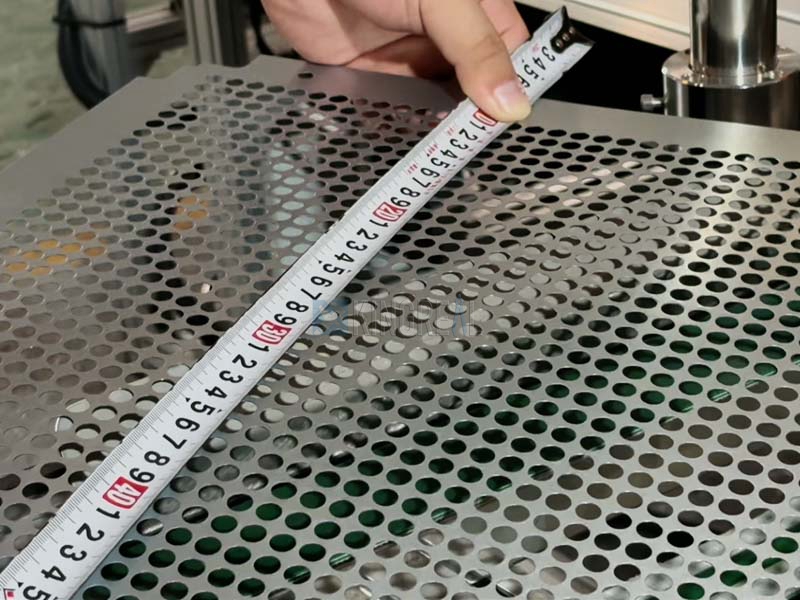

KINGREAL CEILING MACHINERY's metal sheet perforation line is specially designed to make metal coils into perforated metal sheets for subsequent secondary processing. By changing the punching die, the metal sheet perforated machine can produce a variety of types of holes and apertures to meet the needs of different customers.

KINGREAL CEILING MACHINERY's featured metal sheet perforation lines include:

- Coil to coil perforation line

KINGREAL CEILING MACHINERY can equip the coil to coil perforation line with a recoiler to automatically wind the perforated sheet, which is convenient for storage, transportation and secondary processing by customers. This metal sheet perforation line with rewinding is popular with merchants who manufacture washing baskets, filter devices, screens, etc., providing them with production convenience.

- Metal sheet perforation line

KINGREAL CEILING MACHINERY is equipped with a shearing station on the basis of the metal sheet perforation line. After the punching metal sheet is manufactured, it will be accurately cut by the automated shearing station according to the length required by the customer. The metal perforated sheet is widely used in architectural decoration, industry, food processing, chemical pharmaceuticals, environmental protection and energy and other fields.

- Metal ceiling perforation line

KINGREAL CEILING MACHINERY metal ceiling perforation line can be used together with the metal ceiling machine to produce a high-precision metal perforated ceiling. KINGREAL CEILING MACHINERY can provide two tonnage metal punching machines of 125 tons and 160 tons. Engineers will give the best solution based on the specific parameter information such as the area of punching required by the customer and the metal raw materials to be processed.

Suspended ceiling machine

KINGREAL CEILING MACHINERY is able to provide a variety of suspended ceiling roll forming machines, covering the linear strip ceiling machines, open cell ceiling machines and baffle ceiling machines that are in great demand in the market. KINGREAL CEILING MACHINERY is committed to providing customers with comprehensive metal suspended ceiling machine solutions to meet various project needs.

KINGREAL CEILING MACHINERY's featured suspended ceiling production lines include:

The u baffle machine consists of precision parts such as decoiler, precision leveling machine, roll forming machine, shearing system, etc., which can produce various types of baffle ceilings with a width of 25-100mm and a height of 75-300mm, such as U-shaped baffle ceiling, V-shaped baffle ceiling and U-shaped baffle ceiling with U bent.

- Linear strip ceiling machine

KINGREAL CEILING MACHINERY has designed different solutions for the linear strip ceiling roll forming machine, including linear strip ceiling machine with punching station, single-specification linear strip ceiling making machine, and multi-specification linear strip ceiling machine (adjustable width). KINGREAL CEILING MACHINERY's customized linear strip ceiling production line can produce 84R, B-type, C-type and other common strip ceilings on the market.

KINGREAL CEILING MACHINERY’s engineers designed standard grilyato ceiling machines, customized open cell ceiling machines and high-end open cell ceiling making machines according to customer needs. Among them,The high-end open cell ceiling machine is to upgrade the 16-ton punching station in the standard grilyato ceiling machine to a 63-ton punching station, which can punch a row of holes at a time. KINGREAL CEILING MACHINERY's open cell ceiling machines can produce U-shaped, C-shaped and pyramid-shaped grilyato ceilings with high precision.

An Overview of KINGREAL CEILING MACHINERY Factory Workshops

KINGREAL CEILING MACHINERY factory is mainly composed of the following six workshops to ensure efficient and orderly production process:

The processing workshop is the core of KINGREAL CEILING MACHINERY production, equipped with advanced laser cutting machines and CNC bending machines. This workshop can efficiently process raw materials into the required metal parts. Through precise CNC technology, it ensures that the size and shape of each part meet the design requirements, providing high-quality basic components for subsequent production links.

This enables higher production efficiency and more refined forming effects to be achieved when producing metal ceiling machines, metal sheet perforation lines, and suspended ceiling production lines, meeting the market demand for diversified products.

Finished product workshop

The finished product workshop is responsible for the final sorting and packaging of all machines. Machines that have passed various production links will be carefully inspected here to ensure that their appearance and performance meet the standards. The finished product workshop will also classify and package according to customer needs to ensure that they remain intact during transportation and improve customer satisfaction.

Recently, KINGREAL CEILING MACHINERY staff completed the packaging of the ceiling t bar machine in the finished product workshop and successfully sent it to the Indian customer's factory.

Welding workshop

The welding workshop uses a variety of welding technologies, including arc welding, laser welding and spot welding, which can handle metals of different materials and thicknesses. Professionally trained welding workers ensure that the strength and quality of each weld meet industry standards, providing a solid guarantee for the structural stability of the product.

This precise and diverse welding process not only improves the overall quality of the product, but also reduces the subsequent maintenance costs. This is the main reason why customers highly evaluate KINGREAL CEILING MACHINERY's suspended ceiling machines, metal sheet perforated machines and metal ceiling tile production lines.

Raw material workshop

The raw material workshop is mainly responsible for receiving, storing and managing various raw materials required for production. KINGREAL CEILING MACHINERY conducts strict quality inspections on raw materials to ensure that they meet production standards. The workshop is equipped with a scientific warehouse management system to effectively track inventory status, ensure the smooth operation of the production line, and optimize raw material management to improve production efficiency.

Last month, the KINGREAL CEILING MACHINERY team purchased a batch of raw materials for the manufacture of metal ceiling tile production lines. After comprehensive testing, unqualified materials were returned in a timely manner, further ensuring production quality and efficiency.

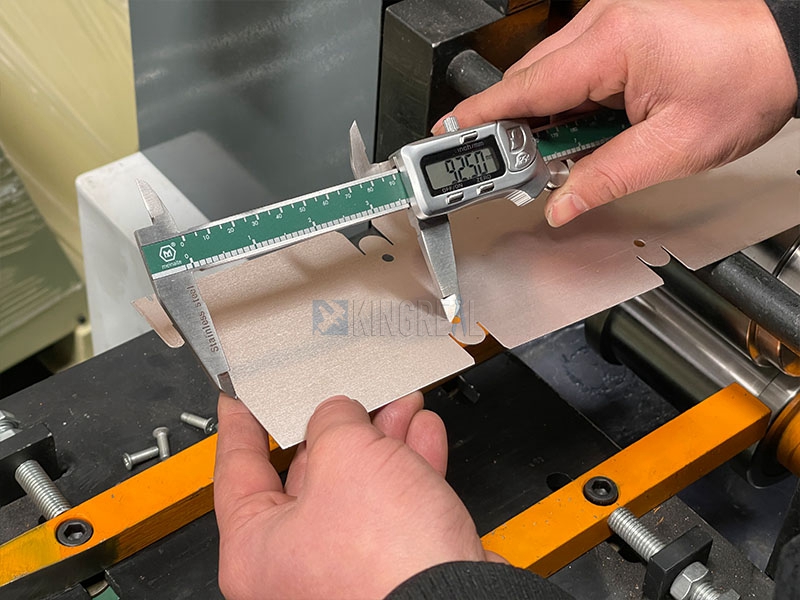

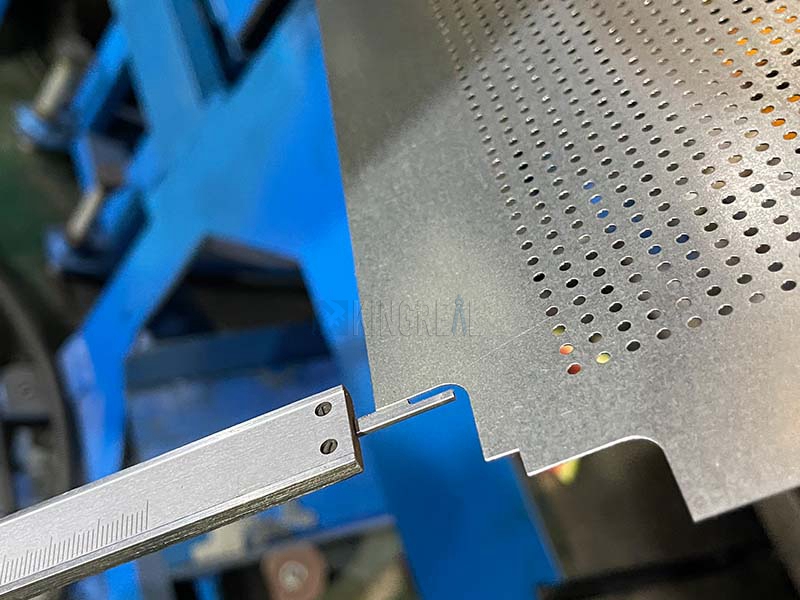

In the quality assurance workshop, KINGREAL CEILING MACHINERY conducts comprehensive inspections on all produced parts and finished products, covering dimensions, strength, surface treatment and other aspects. Equipped with advanced testing instruments and equipment, it ensures that each test is accurate and reliable, providing customers with greater confidence.

KINGREAL CEILING MACHINERY also invited customers who purchased baffle ceiling machines to come to the site to conduct trial tests of u baffle machines with staff.

The assembly workshop is responsible for the final assembly of all parts to form a complete production line. KINGREAL CEILING MACHINERY follows a strict assembly process to ensure that the installation position and connection method of each component meet the design requirements. Professionally trained workers have superb assembly skills and can efficiently complete the machine assembly. After assembly, the machine will undergo a series of rigorous test inspections to ensure that its functions meet customer needs.

Last week, KINGREAL CEILING MACHINERY staff assembled the decoiler, precision leveler, metal punching machine and other components of the metal sheet punching machine one by one to form a complete production line. The staff also sent pictures and videos to customers for real-time communication.

Get the latest price? We'll respond as soon as possible(within 12 hours)