Products Lists

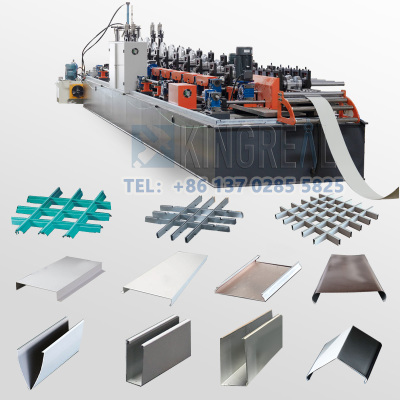

KINGREAL CEILING MACHINERY is committed to providing customers with high-quality metal leveling services. Whether it is thin metal or thick metal, regular metal or irregular metal, we can handle it efficiently. Metal objects processed by the sheet metal straightener can be widely used in aerospace, shipbuilding, automobiles and other fields to meet the needs of different industries. This sheet metal leveling machine is popular in the United States, Canada, Australia, the United Kingdom, Germany, Italy, Belgium, New Zealand, Pakistan, India and other countries. On this page, KINGREAL CEILING MACHINERY will give you a detailed introduction to the types, working principles, application scope and significant advantages of KINGREAL CEILING MACHINERY sheet metal leveling machines. If you are interested in sheet metal flattening machines, welcome to consult!

1. KINGREAL CEILING MACHINERY can Provide Different Types of Sheet Metal Flatteners

KINGREAL CEILING MACHINERY provides a variety of steel plate flattening machines, of which the two most popular ones are 4 high roller sheet metal straighteners and 6 high roller sheet metal leveling machines. They have their own characteristics in working principle, design structure and application scope, which can meet the needs of different customers.

1.1 4 high roller sheet metal leveling machine

The 4 high roller sheet metal flattening machine works by using the "Bausinger effect" of the material. This sheet metal flattener achieves multiple alternating bending in positive and negative directions through repeated stretching and compression between the upper and lower rollers. This process gradually transforms the multiple curvatures into a single curvature, and finally makes the metal sheet flat and uniform. The residual stress of the flattened sheet is small and evenly distributed, which is suitable for manufacturing industries such as engineering machinery, metallurgy, vehicles, metal structures, ships, pressure vessels and chemical machinery.

✦Design features of 4 high roller steel plate flattening machine

(1) Widened design of support rollers: The widened design of the support rollers and the double bearing design ensure the very precise concentric operation of the support rollers, thereby improving the running rigidity of the leveling rollers.

(2) Reduce surface texture: The design of the support rollers greatly reduces the leveling texture on the surface of the parts caused by the support rollers, ensuring the surface quality of the treated metal.

✦Application areas of 4 high roller sheet metal flattening machine

The 4 high roller sheet metal leveling machine is suitable for various industries, especially in metal material warehousing, sheet distribution and other industries. Users can use it alone, or match it with various sheet and strip processing and forming equipment as needed to achieve a wider range of functional extensions.

1.2 6 high roller sheet metal leveling machine

The working principle of the 6 high roller sheet metal leveling machine is different from that of the 4 high roller sheet metal straightener. In this machine, the flexural force generated by the leveling roller and auxiliary roller is borne by the support wheel. The joint action of multiple support wheels greatly improves the stress state of the leveling roller, which is conducive to the conduction of the leveling pressure.

✦Materials and Technology of 6 high roller sheet metal flattener

The leveling roller of the 6 high roller sheet metal straightener uses high-grade alloy steel Gcr15 processed by smelting and forging. After the roller body is heat-treated, the surface is chrome-plated to improve wear resistance and corrosion resistance. Its surface hardness can reach HRC60-64, and its mechanical properties are excellent, with tensile strength ≤900N/mm, yield limit ≤800N/mm, and elongation coefficient ≥15%. These characteristics make the 6 high roller sheet metal leveling machine perform well in processing high-strength metals.

✦Application Fields of 6 high roller sheet metal straightener

The 6 high roller sheet metal flattening machine is suitable for processing metal materials with higher requirements, and is widely used in aerospace, automobile manufacturing, heavy industry and high-end equipment manufacturing.

2.KINGREAL CEILING MACHINERY Sheet Metal Flattener can Level Different Types of Objects

KINGREAL CEILING MACHINERY sheet metal leveling machine can level various metal materials, including iron, aluminum, steel, copper, stainless steel, etc. And KINGREAL CEILING MACHINERY steel plate flattening machine can not only process metal sheets, but also a variety of metal objects, including perforated mesh, metal rods, metal parts, metal strips and metal plates. After leveling, these objects can significantly improve their flatness and quality to meet different industrial needs.

(1)Perforated mesh

Perforated mesh is a common metal material widely used in the construction, filtration and decoration industries. After leveling, the hole position accuracy and overall flatness of the perforated mesh are significantly improved, which enables it to better meet the design requirements in the application. The leveled perforated mesh is not only beautiful, but also can effectively improve its load-bearing capacity and durability during use.

(2)Metal rod

Metal rods are commonly used in machinery manufacturing, construction and automotive industries. The surface of the metal rod after leveling is smooth and the size is accurate, which can effectively improve its processing accuracy and strength in subsequent processing. This is especially important in many high-demand applications.

(3)Metal parts

Metal parts play an important role in the manufacture of aerospace and automotive parts. Leveling can eliminate stress, improve strength and durability of parts, and ensure stability under high load and high temperature environments. Leveled metal parts can better adapt to complex assembly requirements and improve the quality of the overall product.

(4)Metal strips

Metal strips are important materials for manufacturing furniture, buildings and machinery. Through leveling, the flatness and straightness of metal strips are improved, which not only improves the appearance of the product, but also ensures accuracy during installation, making the entire structure more stable.

(5)Metal plates

Metal plates are widely used in manufacturing, especially in welding and processing industries. After leveling, metal plates are suitable for welding and processing with higher requirements, which can significantly improve the quality and strength of welding, reduce welding defects, and improve the qualified rate of products.

3. Advantages of KINGREAL CEILING MACHINERY Sheet Metal Straightener

(1) Adjustable leveling roller gap

The leveling roller gap of KINGREAL CEILING MACHINERY sheet metal flattening machine can be precisely adjusted through the advanced touch screen human-machine interface. This design enables the operator to quickly set the optimal roller gap according to the thickness and characteristics of different materials to achieve the best leveling effect. The adjustable roller gap not only improves the flexibility of leveling, but also enables the equipment to adapt to the processing needs of various metal types. For example, for thicker metal sheets, the operator can increase the roller gap to ensure sufficient pressure and uniform leveling effect. Conversely, for thin metal, reducing the roller gap can effectively prevent damage and deformation of the material.

(2) Flexible feed speed adjustment

The feed speed of the KINGREAL CEILING MACHINERY sheet metal leveling machine can be adjusted according to the actual production situation to ensure an efficient working rhythm in different production links. This function is particularly suitable for industrial environments that require rapid production. Operators can make dynamic adjustments based on the fluidity, processing requirements and production efficiency of the material. Flexible feed speed adjustment not only improves production efficiency, but also reduces energy consumption, allowing enterprises to achieve the goal of energy conservation and emission reduction while ensuring product quality.

(3) Strong anti-fouling rollers

The rollers of KINGREAL CEILING MACHINERY steel plate flattening machines are extremely anti-fouling, which means that during long-term operation, dirt and metal chips are not easy to accumulate on the surface of the equipment, and maintenance work is also easier. Cleaning the rollers can be completed with a simple cleaning step, which greatly reduces the downtime caused by cleaning work. Strong anti-fouling not only extends the service life of the sheet metal straightener, but also reduces maintenance costs, so that enterprises benefit in long-term operations.

(4) High-precision flatness

The flatness of KINGREAL CEILING MACHINERY sheet metal flattening machines can reach up to 0.1mm/m², which is very competitive in the industry. The high-precision leveling effect ensures the consistency and stability of the processed metal parts in subsequent processing and application, meeting the strict requirements of high-end manufacturing. For example, in aerospace and automotive manufacturing, the accuracy of the material is crucial to the performance of the final product. By using KINGREAL CEILING MACHINERY steel plate flattening machines, companies can effectively reduce production defects caused by material unevenness and improve product qualification and market competitiveness.

(5) Versatility and applicability

KINGREAL CEILING MACHINERY sheet metal straighteners are not only suitable for leveling metal sheets, but can also handle a variety of metal objects such as perforated mesh, metal rods, metal parts, etc. This versatility enables the sheet metal flattening machine to meet the needs of different industries and provide customers with more comprehensive solutions. Whether it is the manufacturing industry, construction industry or automotive industry, KINGREAL CEILING MACHINERY sheet metal leveling machines can provide customers with high-quality leveling services.

1. KINGREAL CEILING MACHINERY can Provide Different Types of Sheet Metal Flatteners

KINGREAL CEILING MACHINERY provides a variety of steel plate flattening machines, of which the two most popular ones are 4 high roller sheet metal straighteners and 6 high roller sheet metal leveling machines. They have their own characteristics in working principle, design structure and application scope, which can meet the needs of different customers.

1.1 4 high roller sheet metal leveling machine

The 4 high roller sheet metal flattening machine works by using the "Bausinger effect" of the material. This sheet metal flattener achieves multiple alternating bending in positive and negative directions through repeated stretching and compression between the upper and lower rollers. This process gradually transforms the multiple curvatures into a single curvature, and finally makes the metal sheet flat and uniform. The residual stress of the flattened sheet is small and evenly distributed, which is suitable for manufacturing industries such as engineering machinery, metallurgy, vehicles, metal structures, ships, pressure vessels and chemical machinery.

✦Design features of 4 high roller steel plate flattening machine

(1) Widened design of support rollers: The widened design of the support rollers and the double bearing design ensure the very precise concentric operation of the support rollers, thereby improving the running rigidity of the leveling rollers.

(2) Reduce surface texture: The design of the support rollers greatly reduces the leveling texture on the surface of the parts caused by the support rollers, ensuring the surface quality of the treated metal.

✦Application areas of 4 high roller sheet metal flattening machine

The 4 high roller sheet metal leveling machine is suitable for various industries, especially in metal material warehousing, sheet distribution and other industries. Users can use it alone, or match it with various sheet and strip processing and forming equipment as needed to achieve a wider range of functional extensions.

1.2 6 high roller sheet metal leveling machine

The working principle of the 6 high roller sheet metal leveling machine is different from that of the 4 high roller sheet metal straightener. In this machine, the flexural force generated by the leveling roller and auxiliary roller is borne by the support wheel. The joint action of multiple support wheels greatly improves the stress state of the leveling roller, which is conducive to the conduction of the leveling pressure.

✦Materials and Technology of 6 high roller sheet metal flattener

The leveling roller of the 6 high roller sheet metal straightener uses high-grade alloy steel Gcr15 processed by smelting and forging. After the roller body is heat-treated, the surface is chrome-plated to improve wear resistance and corrosion resistance. Its surface hardness can reach HRC60-64, and its mechanical properties are excellent, with tensile strength ≤900N/mm, yield limit ≤800N/mm, and elongation coefficient ≥15%. These characteristics make the 6 high roller sheet metal leveling machine perform well in processing high-strength metals.

✦Application Fields of 6 high roller sheet metal straightener

The 6 high roller sheet metal flattening machine is suitable for processing metal materials with higher requirements, and is widely used in aerospace, automobile manufacturing, heavy industry and high-end equipment manufacturing.

2.KINGREAL CEILING MACHINERY Sheet Metal Flattener can Level Different Types of Objects

KINGREAL CEILING MACHINERY sheet metal leveling machine can level various metal materials, including iron, aluminum, steel, copper, stainless steel, etc. And KINGREAL CEILING MACHINERY steel plate flattening machine can not only process metal sheets, but also a variety of metal objects, including perforated mesh, metal rods, metal parts, metal strips and metal plates. After leveling, these objects can significantly improve their flatness and quality to meet different industrial needs.

(1)Perforated mesh

Perforated mesh is a common metal material widely used in the construction, filtration and decoration industries. After leveling, the hole position accuracy and overall flatness of the perforated mesh are significantly improved, which enables it to better meet the design requirements in the application. The leveled perforated mesh is not only beautiful, but also can effectively improve its load-bearing capacity and durability during use.

(2)Metal rod

Metal rods are commonly used in machinery manufacturing, construction and automotive industries. The surface of the metal rod after leveling is smooth and the size is accurate, which can effectively improve its processing accuracy and strength in subsequent processing. This is especially important in many high-demand applications.

(3)Metal parts

Metal parts play an important role in the manufacture of aerospace and automotive parts. Leveling can eliminate stress, improve strength and durability of parts, and ensure stability under high load and high temperature environments. Leveled metal parts can better adapt to complex assembly requirements and improve the quality of the overall product.

(4)Metal strips

Metal strips are important materials for manufacturing furniture, buildings and machinery. Through leveling, the flatness and straightness of metal strips are improved, which not only improves the appearance of the product, but also ensures accuracy during installation, making the entire structure more stable.

(5)Metal plates

Metal plates are widely used in manufacturing, especially in welding and processing industries. After leveling, metal plates are suitable for welding and processing with higher requirements, which can significantly improve the quality and strength of welding, reduce welding defects, and improve the qualified rate of products.

3. Advantages of KINGREAL CEILING MACHINERY Sheet Metal Straightener

(1) Adjustable leveling roller gap

The leveling roller gap of KINGREAL CEILING MACHINERY sheet metal flattening machine can be precisely adjusted through the advanced touch screen human-machine interface. This design enables the operator to quickly set the optimal roller gap according to the thickness and characteristics of different materials to achieve the best leveling effect. The adjustable roller gap not only improves the flexibility of leveling, but also enables the equipment to adapt to the processing needs of various metal types. For example, for thicker metal sheets, the operator can increase the roller gap to ensure sufficient pressure and uniform leveling effect. Conversely, for thin metal, reducing the roller gap can effectively prevent damage and deformation of the material.

(2) Flexible feed speed adjustment

The feed speed of the KINGREAL CEILING MACHINERY sheet metal leveling machine can be adjusted according to the actual production situation to ensure an efficient working rhythm in different production links. This function is particularly suitable for industrial environments that require rapid production. Operators can make dynamic adjustments based on the fluidity, processing requirements and production efficiency of the material. Flexible feed speed adjustment not only improves production efficiency, but also reduces energy consumption, allowing enterprises to achieve the goal of energy conservation and emission reduction while ensuring product quality.

(3) Strong anti-fouling rollers

The rollers of KINGREAL CEILING MACHINERY steel plate flattening machines are extremely anti-fouling, which means that during long-term operation, dirt and metal chips are not easy to accumulate on the surface of the equipment, and maintenance work is also easier. Cleaning the rollers can be completed with a simple cleaning step, which greatly reduces the downtime caused by cleaning work. Strong anti-fouling not only extends the service life of the sheet metal straightener, but also reduces maintenance costs, so that enterprises benefit in long-term operations.

(4) High-precision flatness

The flatness of KINGREAL CEILING MACHINERY sheet metal flattening machines can reach up to 0.1mm/m², which is very competitive in the industry. The high-precision leveling effect ensures the consistency and stability of the processed metal parts in subsequent processing and application, meeting the strict requirements of high-end manufacturing. For example, in aerospace and automotive manufacturing, the accuracy of the material is crucial to the performance of the final product. By using KINGREAL CEILING MACHINERY steel plate flattening machines, companies can effectively reduce production defects caused by material unevenness and improve product qualification and market competitiveness.

(5) Versatility and applicability

KINGREAL CEILING MACHINERY sheet metal straighteners are not only suitable for leveling metal sheets, but can also handle a variety of metal objects such as perforated mesh, metal rods, metal parts, etc. This versatility enables the sheet metal flattening machine to meet the needs of different industries and provide customers with more comprehensive solutions. Whether it is the manufacturing industry, construction industry or automotive industry, KINGREAL CEILING MACHINERY sheet metal leveling machines can provide customers with high-quality leveling services.

Get the latest price? We'll respond as soon as possible(within 12 hours)