Perforated Sheet Leveler Machine

The KINGREAL CEILING MACHINERY Perforated Sheet Leveler Machine is an industrial machine designed for the leveling of perforated sheet metal, specifically designed to help customers solve the problem of warped edges and unevenness of perforated sheet metal.

Helping customers to solve the problem of fine flatness of products is the direction that KINGREAL CEILING MACHINERY always insists on.

- KINGREAL CEILING MACHINERY

- CHINA

- 90 DAYS

- 9999

Details

Video About Plate Leveller

Description About Perforated Sheet Leveler Machine

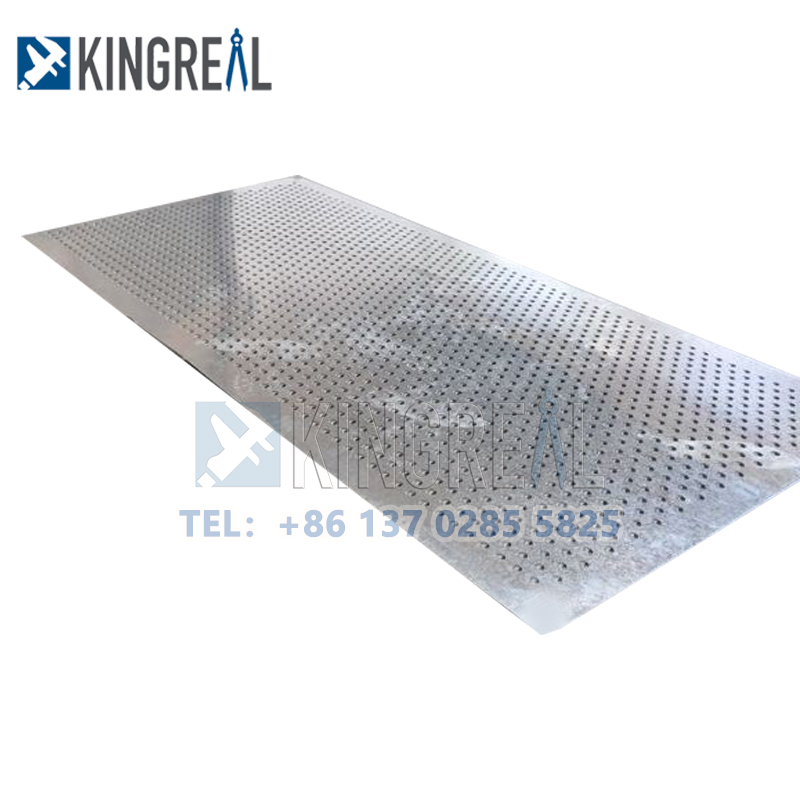

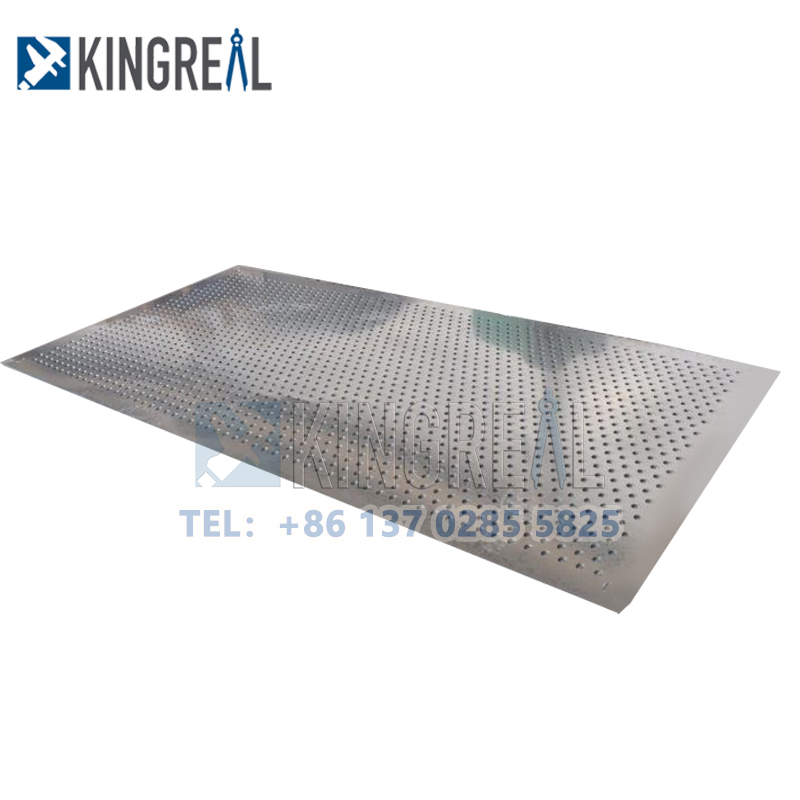

KINGREAL CEILING MACHINERY PERFORATED PLATE LEVELER is a kind of industrial equipment specialized in the leveling of punched metal plates. Unlike the traditional leveler, due to the discontinuity of the entire surface of the product caused by the specificity of the hole diameter of the punched plate, it is necessary to add more sets of rolls and adjust the distance between the rolls in order to more closely meet the leveling requirements of punched metal plates.

The perforated sheet leveler eliminates warping, waving or bending deformation of the sheet after punching by inter-roll pressure and repeated bending operations. Due to the unique nature of perforated sheets, the leveler requires finer control to ensure that no further damage is caused to the sheet during the leveling process.

Technical Specification

Roller Diameter | φ30mm |

Roller Number | 21 |

Speed | 0-10m/Min |

Leveled Width | <1600mm |

Rated Plate Thickness | 0.5~2.0mm |

Maximum Thickness | 3 |

Shortest Workpiece | 60mm |

More Technical Details About Perforated Sheet Leveling

1. The perforated sheet leveling machine usually has several sets of upper and lower leveling rollers, sometimes it may have more rollers than the ordinary leveling machine, especially the small diameter rollers, in order to better adapt to the hole structure of the perforated sheet. At the same time, the distance between the rolls can also be adjusted according to the thickness of the plate to ensure that different thicknesses and hole densities of the plate can be effectively leveled. In order to ensure the stability of the leveling rolls during processing, the support roll system supports the work rolls and prevents them from deforming. At the same time, the support system handles the perforated material in such a way as to avoid excessive forces being concentrated in the perforated area, thus preventing damage to the material.

2. Due to the presence of discontinuous holes in the punched material, the pressure distribution needs to be very precise, so the equipment is usually equipped with a more advanced pressure control system, utilizing hydraulics or servo systems to achieve precise pressure regulation.

3. The shape, thickness and hole distribution of perforated sheets vary greatly, so the leveler needs to be highly adaptable, allowing flexible adjustment of parameters for different sheets.

Features Of Perforated Sheet Leveler Machine

1.Greater leveling accuracy is ensured by the auxiliary wheel, which narrows the space between the upper and lower straightening rollers;

2. PLC control, visual input, editing, modifying, and storing process parameters; a 10-inch high-precision touch screen display; Raise and lower the descent point;

3. It only takes a few minutes to make stamped plates, parts, and parts flat and nearly stress-free;

4. A metal plate is bent repeatedly via a number of staggered leveling rollers in a precision leveling machine; the amount of bending can be changed to accomplish the necessary bending plan for leveling lock without causing damage to the plate's appearance;

5. The length of the metal fibers gradually stabilizes after repeated bending of the sheet metal, and the material's internal tension is also removed. The metal sheet flattens naturally.

6. The precision leveling machine has significantly increased leveling efficiency and entered the continuous production line by utilizing continuous and repeated bending technology, which has eliminated the technical dependence on traditional leveling experience and saved a significant amount of labor costs;

7. Using an universal joint transmission joint results in stronger, more consistent transmission force, quieter, and longer-lasting equipment.

Application Of Perforated Plate Leveler Machine

Perforated sheet leveling machines are widely used in industries and application scenarios where precision is required for perforated metal sheets. Perforated sheets have good air permeability, weight reduction properties, etc.

They are commonly used in perforated sheets that require aesthetics and leveling, such as curtain walls and ceilings, to make ventilation panels with good air permeability, perforated panels in the automotive industry, and in the manufacture of filters and screens, where leveling is a key step to ensure functionality and precision.

KINGREAL CEILING MACHINERY After-sales Service

KINGREAL CEILING MACHINERY has a professional team dedicated to providing exceptional service and support to its customers. The specific team composition is as follows:

Customer service team

KINGREAL CEILING MACHINERY's customer service team provides 24-hour online service, through online meetings, phone calls, emails and other forms, timely reply to customer inquiries about the perforated sheet metal straightener. Customer service staff are professionally trained in perforated plate leveler knowledge to answer customer questions quickly and accurately, ensuring that customers have access to the necessary support and information at any time. This efficient response mechanism allows customers to get help quickly when they encounter problems, reducing the inconvenience in production.

Engineer team

KINGREAL CEILING MACHINERY can also send professional engineers to the customer's plant to provide training services on the installation and operation of the perforated plate leveler. Engineers will provide on-site guidance according to customers' specific requirements to ensure that customers can fully grasp the use and maintenance skills of the perforated plate leveler. In addition, if there is a failure during use, KINGREAL CEILING MACHINERY will send engineers to the site as soon as possible to quickly find out the problem and solve it to ensure that the customer's production activities are not affected.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)